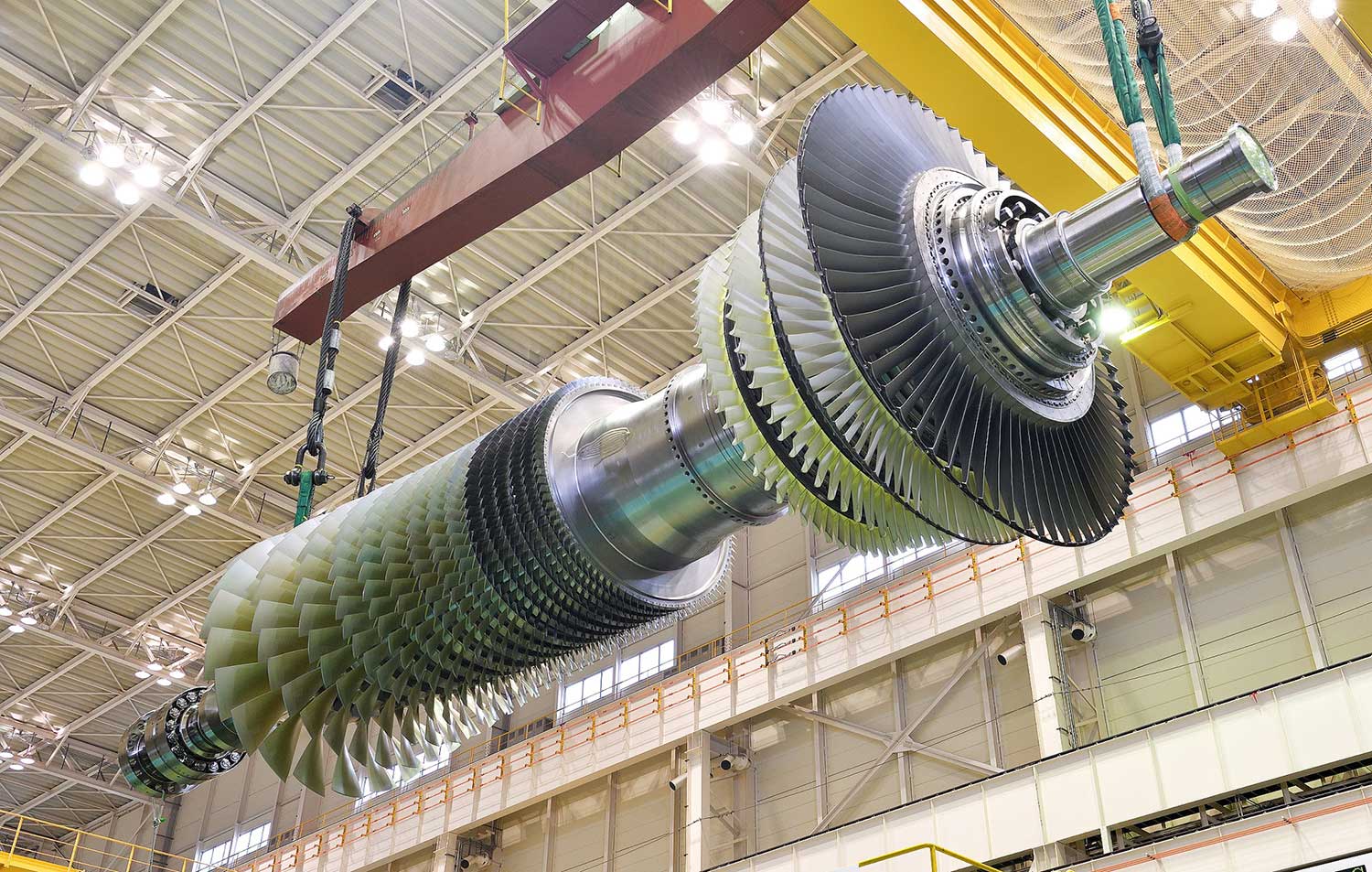

World's most efficient large GTCC power plant

Mitsubishi Heavy Industries, Ltd.

Outline

As the most reliable and effective strategies to realize a decarbonized society, we have been committed to improving the efficiency of a natural gas-fired gas turbine, a thermal power system with the lowest CO2 emissions.

Since 2004, MHI Group has participated in the national project “1,700 ℃ class Ultrahigh-Temperature Gas Turbine Component Technology Development” and developed the latest technology necessary for higher temperature/efficiency.

Utilizing this technology, we have introduced the world's first 1,600 ℃ class, high efficiency gas turbine around the world.

Currently, for further improvement in efficiency, we have been preparing for demonstration of the next generation 1,650 ℃ class gas turbine, using an enhanced air-cooled system for cooling the combustor, ultra-thick TBC (thermal barrier coating) and a compressor with a high pressure ratio as core technologies.

After the commercialization of 1650℃ class gas turbine, we will continue research and development toward the commercialization for further efficiency and operability, thereby contributing to the conservation of global environment and the stable supply of energy.

Description

【Objective】

Natural gas-fired gas turbine combined cycle (GTCC) is the most efficient and has the lowest CO2 emissions of any commercial thermal power plant. Our objective is to improve the power generation efficiency of approx. 62% (LHV) of the current 1600℃ class gas turbines, thereby saving energy and reducing CO2 emissions.

【Issues and Actions】

To improve the efficiency of a gas turbine, it is required to increase combustion temperature and increase the pressure ratio of the compressor. In order to increase the combustion temperature, cooling and heat shielding of components in both combustors and turbines are required to maintain the temperature of the each part below the designed temperature.

Regarding the combustor, the steam-cooled system has been adopted for the 1600℃ class gas turbine, on the other hand, the enhanced air-cooled system using discharged air from the air compressor is adopted for the 1650℃ class. Using this system, further improvement in the thermal efficiency and the operability of the entire plant is expected.

Regarding the turbine, it is important to ensure the durability of the thermal barrier coating (TBC) due to the increase in its thickness. The durability of TBC developed based on the technology resulting from the national project was confirmed through the thermal-cycle-test and the actual equipment verification.

In order to increase the pressure ratio of the compressor, the flow area at the outlet of compressor is reduced, which may affect the stability of the compressor during start-up. However, the actual equipment verification of the compressor confirmed good starting characteristics and good aerodynamic performance.

These component technologies have been verified as individual components, and actual equipment verification of the 1650℃ class gas turbine is planned at the verification facility in our Takasago Works. After verifying the reliability and the operability of the gas turbine, we are aiming for its commercialization.

【Effect】

When the 1650 ℃ class gas turbine is adopted to a natural gas-fired GTCC, power generation efficiency of 64% (LHV) can be achieved, which can reduce CO2 emissions by approx. 50% compared with conventional coal-fired power plant. This will lead to important contribution to the conservation of global environment and the stable supply of energy.

Partner(s)

Mitsubishi Power, Ltd.

Other Innovation Challenges

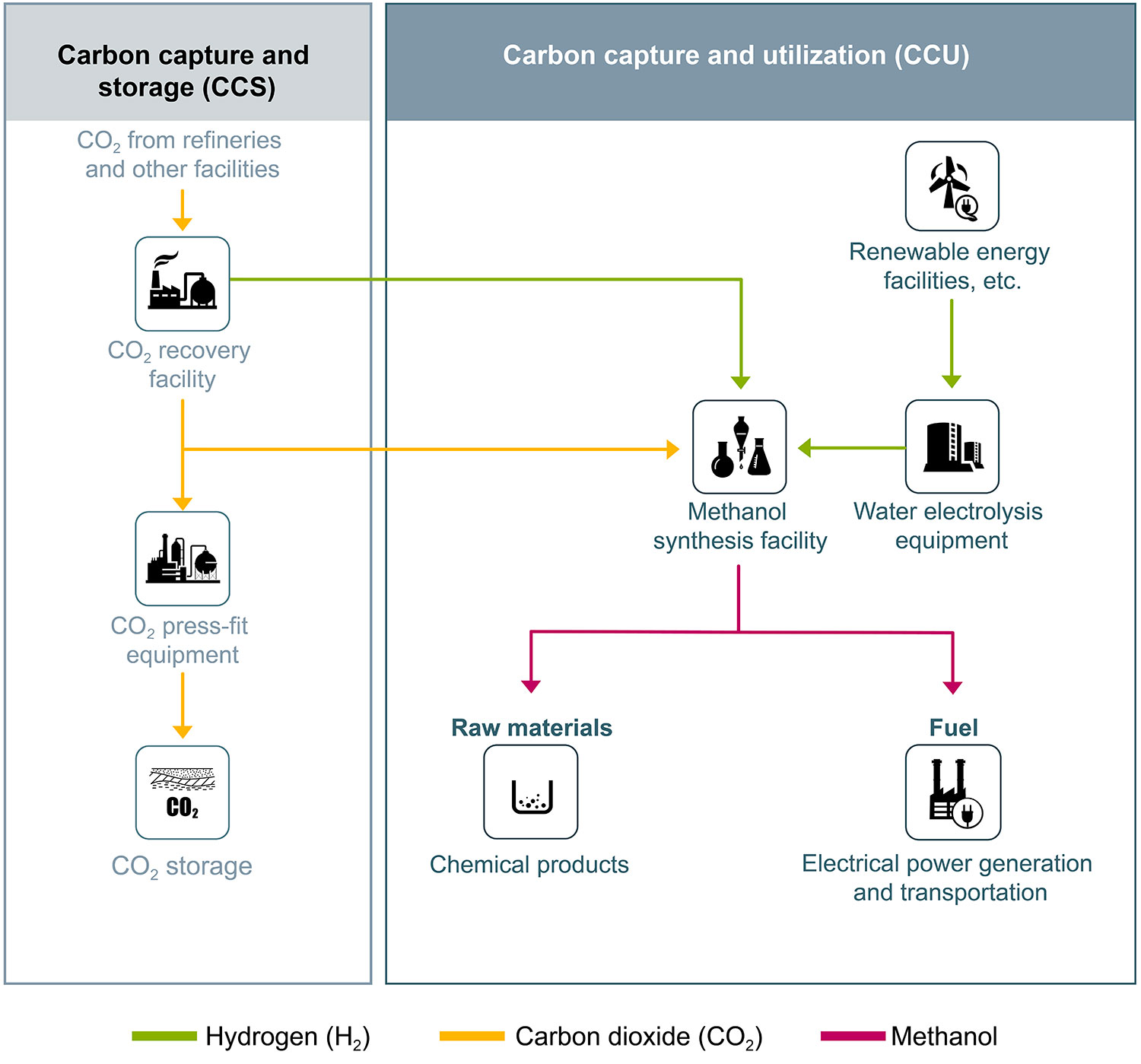

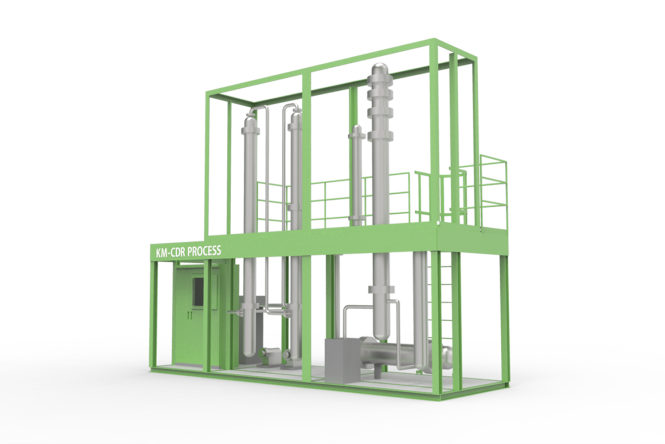

Commercialization of “carbon neutral” and “carbon negative” by implementing carbon capture technology

Mitsubishi Heavy Industries, Ltd.

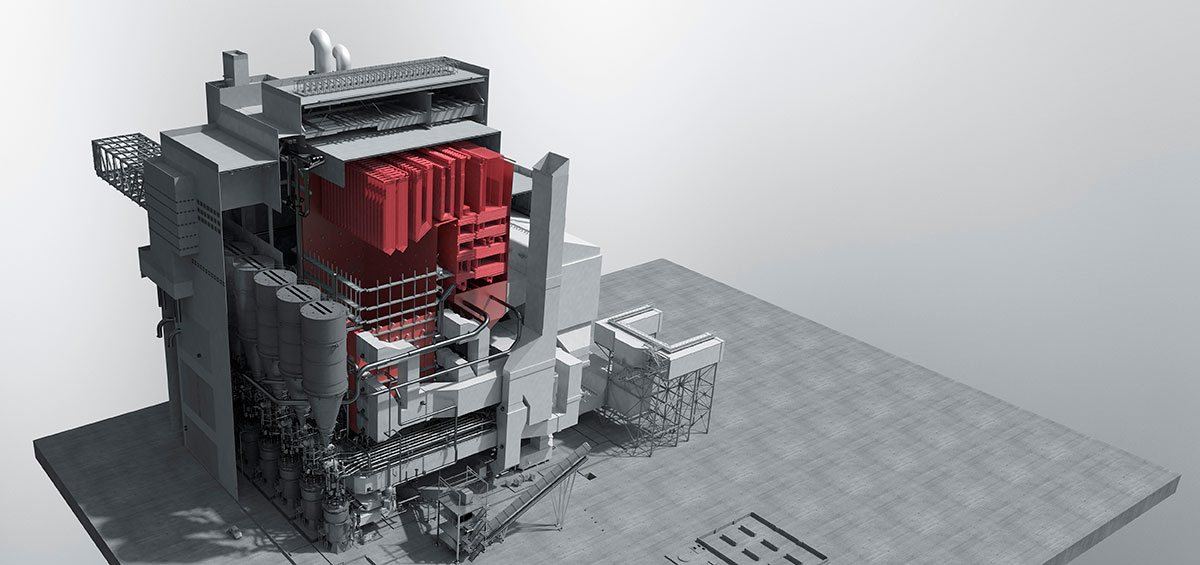

Decarbonization technology of Waste to Energy Facilities

Mitsubishi Heavy Industries, Ltd.

Dissemination of Low-Carbon Stable Energy Infrastructure Based on IGCC Technology

Mitsubishi Heavy Industries, Ltd.

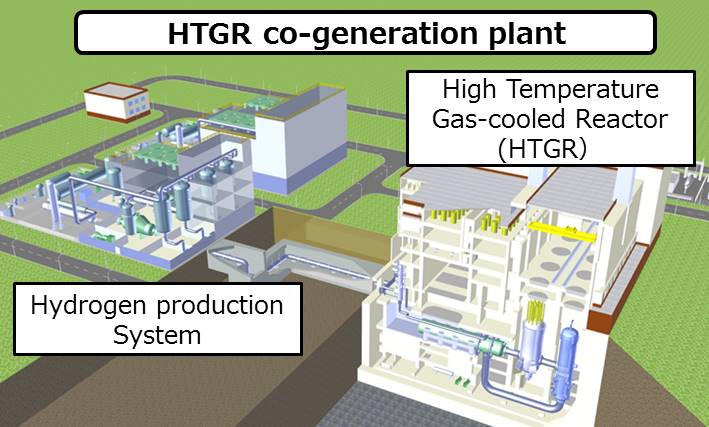

High-Temperature Gas-cooled Reactor co-generation for hydrogen production

Mitsubishi Heavy Industries, Ltd.

Promotion of centrifugal chillers using low-GWP refrigerant across full capacity range

Mitsubishi Heavy Industries, Ltd.

QoEnTM approach – A Quantitative Index to suggest the direction toward High-quality Energy Infrastructure

Mitsubishi Heavy Industries, Ltd.

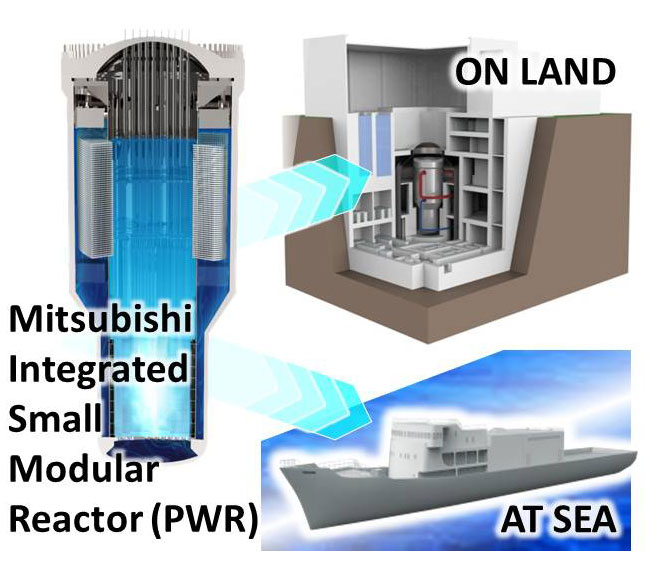

SMR Development for Small Grit Power Reactors and Mobile Reactors

Mitsubishi Heavy Industries, Ltd.

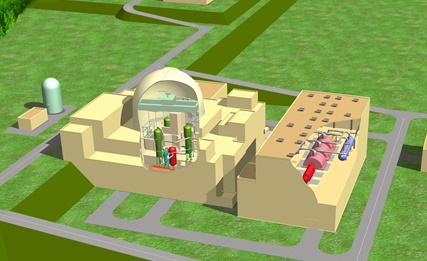

the next-generation light water reactor achieving the world's highest safety and economic efficiency

Mitsubishi Heavy Industries, Ltd.

Triple hybrid stand–alone power generation system

Mitsubishi Heavy Industries, Ltd.

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION