Carbon Recycling Methanol Production

Mitsubishi Heavy Industries, Ltd.

Outline

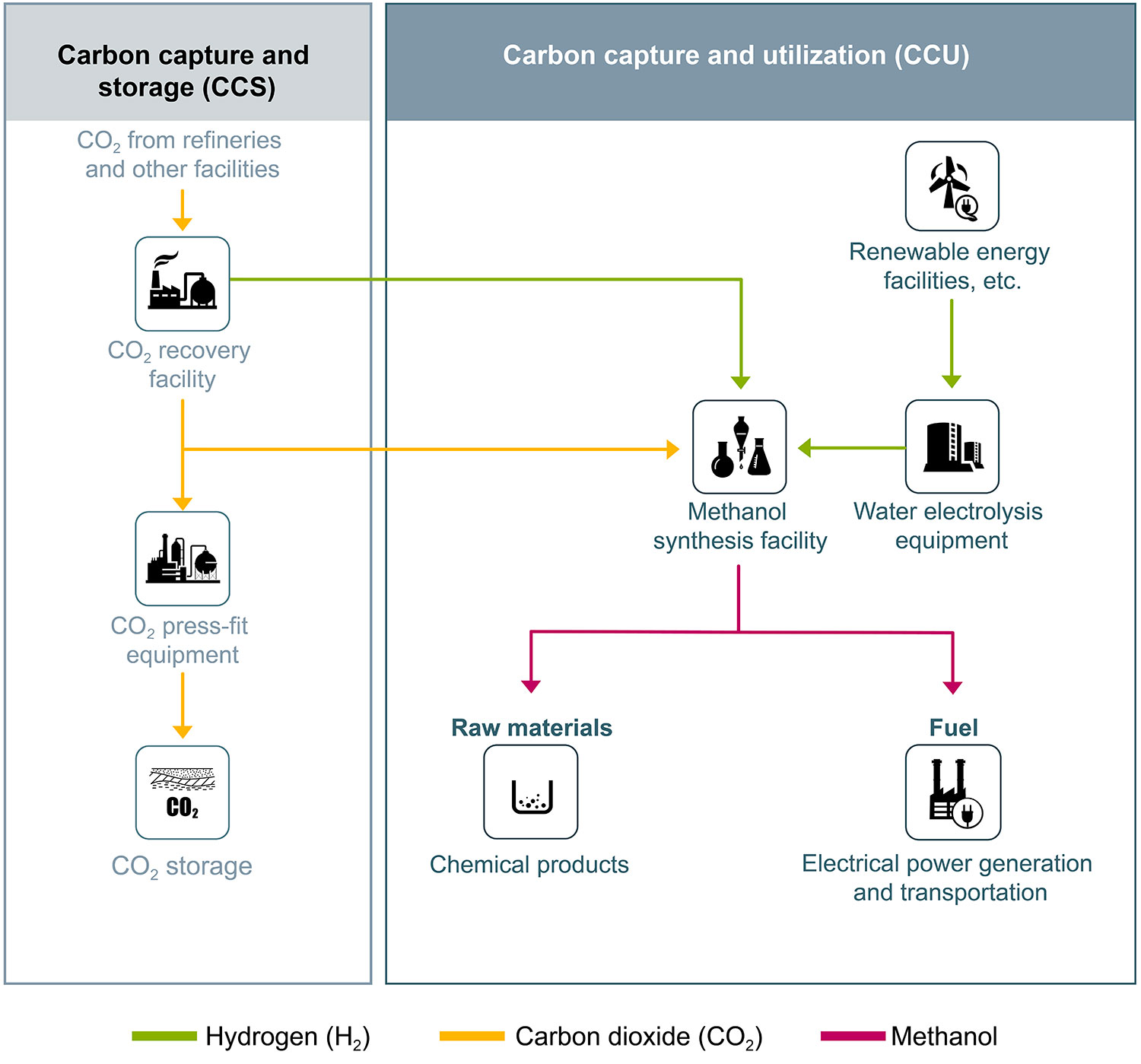

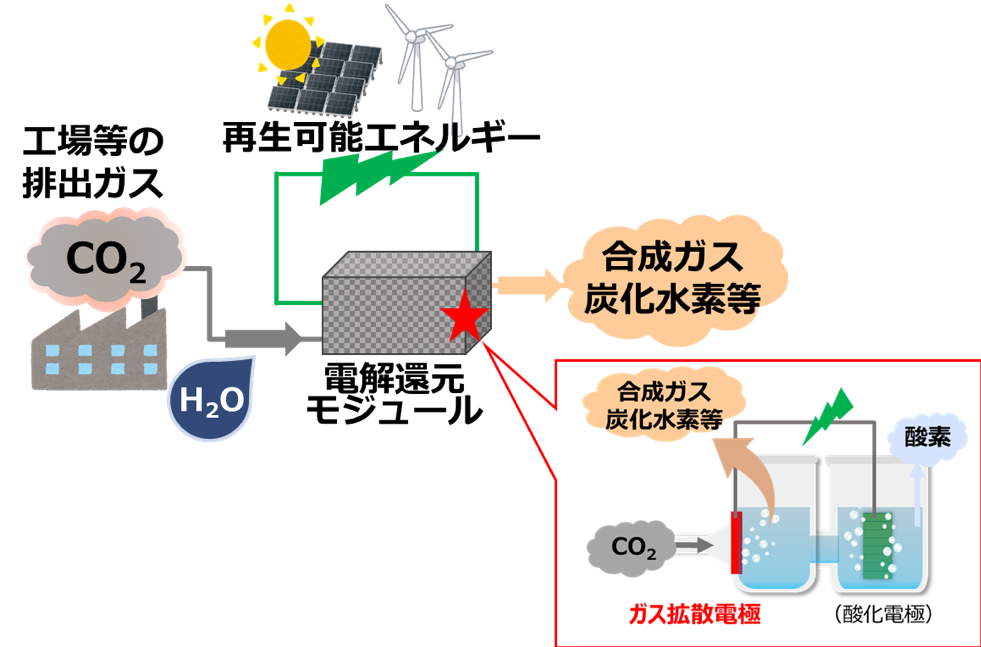

Stepping toward the realization of decarbonized society, MHI Group will take on a challenge to enhance further development of producing methanol synthesized by non-fossil raw materials carbon dioxide (CO2) captured from various emitted flue gases and hydrogen (H2) processed by renewable energy.

Methanol as raw material with stable demand for chemical products as well as fuel for electric power generation and transportation is one of the chemical products to be produced utilizing the technology for “Carbon Recycling” which considers carbon dioxide (CO2) as a source of carbon and enables to reduce CO2. Taking into account the effects of reducing the environmental load, the technology development trends and potential technical capacity of renewable hydrogen, we will proactively contribute to establish a decarbonized society through relevant demonstration projects.

Description

Methanol is generally produced from a synthesis gas mainly composed of H2 and carbon monoxide (CO) processed from fossil oriented hydrocarbon as a raw material, but methanol can also be synthesized from raw material gases of H2 and CO2. However, reaction efficiency of CO2 is significantly lower than that of synthesis gas, furthermore, the same amount of accessory water is simultaneously produced as methanol. Therefore, in order to utilize CO2, establishment of an optimal methanol synthesis whole process, which enables to perform long term stable synthesis, is required.

In addition, one of the widely recognized challenges for producing methanol with carbon recycling technology by renewable hydrogen is its economics of project. Our Group considers that it is also important to conduct comprehensive analysis for scale-up effect to small-scale standardized efficiency for the purpose of reducing overall cost.

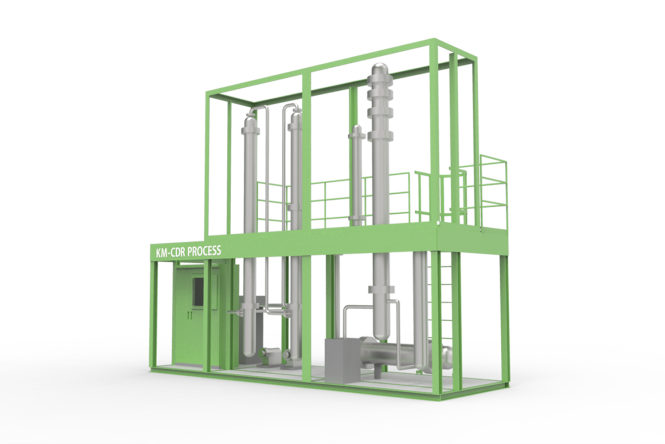

MHI Group future prospect includes an examination of basic design for optimizing plant configuration to produce approximately 10 to 20 metric ton per day of methanol by captured CO2 with H2 processed through water electrolysis having maximum capacity of 10MW, which is currently under development.

Producing methanol by carbon recycling is economically less efficient than the methanol derived from conventional fossil raw materials, however, pursuing further cost reduction by employing for the latest element technologies and expecting consolidation of legislations related to global warming countermeasures, we aim for bringing the same market value as the methanol on the basis of fossil material.

MHI Group will actively continue to contribute to the establishment of a carbon-free society and driving economic development while ensuring environmental conservation.

In addition, MHI Group and Mitsubishi Gas Chemical Company (MGC) will collaborate on research activities for CO2 Capture and Utilization (CCU) in order to produce methanol from captured CO2 by utilizing the demonstration plant currently employed for CO2 Capture and Storage (CCS) at Tomakomai City, Hokkaido, Japan on the project selected by the New Energy and Industrial Technology Development Organization (NEDO). The research is expected to run until February 2021.

Partner(s)

Mitsubishi Gas Chemical Company. Inc

Mitsubishi Heavy Industries Engineering, Ltd.

Mitsubishi Power, Ltd.

Other Innovation Challenges

Commercialization of “carbon neutral” and “carbon negative” by implementing carbon capture technology

Mitsubishi Heavy Industries, Ltd.

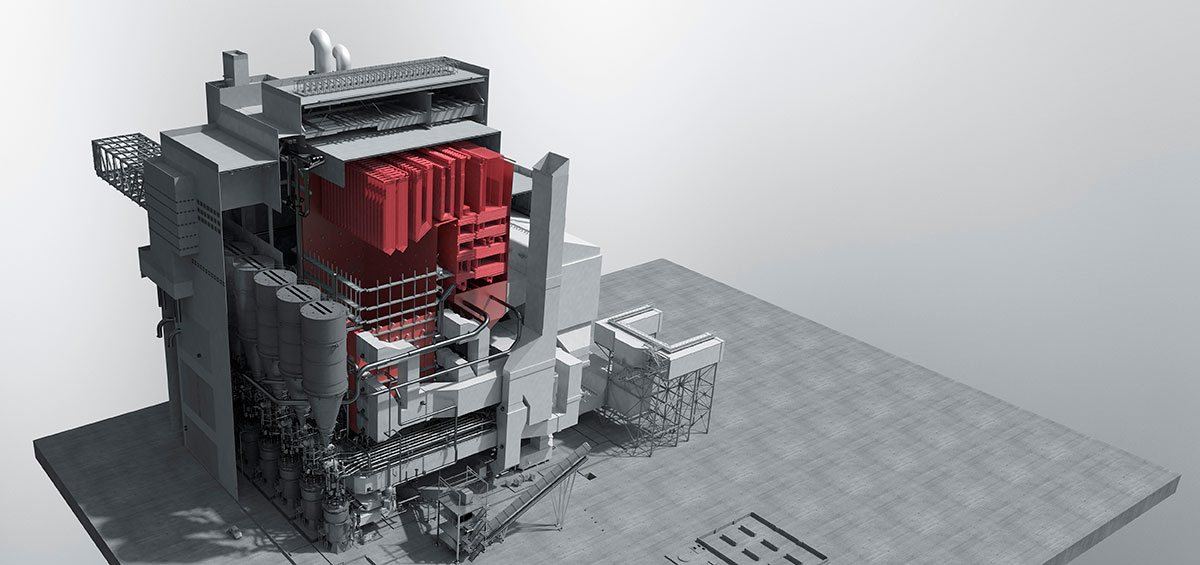

Decarbonization technology of Waste to Energy Facilities

Mitsubishi Heavy Industries, Ltd.

Dissemination of Low-Carbon Stable Energy Infrastructure Based on IGCC Technology

Mitsubishi Heavy Industries, Ltd.

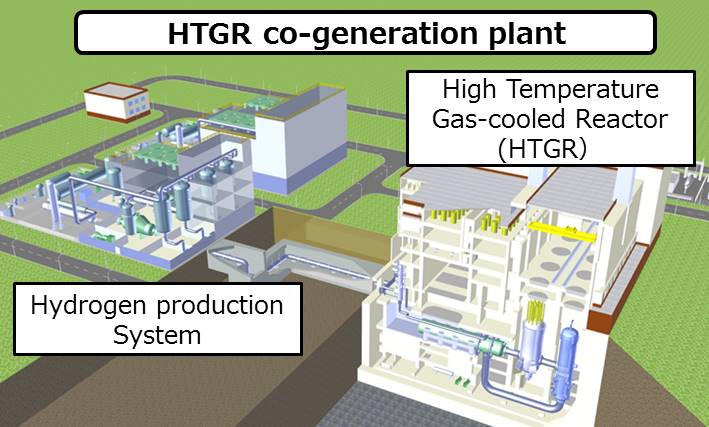

High-Temperature Gas-cooled Reactor co-generation for hydrogen production

Mitsubishi Heavy Industries, Ltd.

Promotion of centrifugal chillers using low-GWP refrigerant across full capacity range

Mitsubishi Heavy Industries, Ltd.

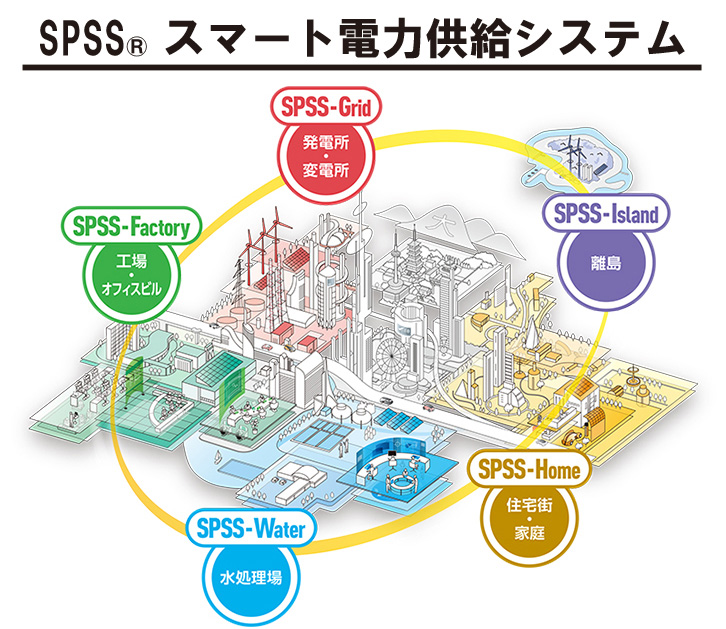

QoEnTM approach – A Quantitative Index to suggest the direction toward High-quality Energy Infrastructure

Mitsubishi Heavy Industries, Ltd.

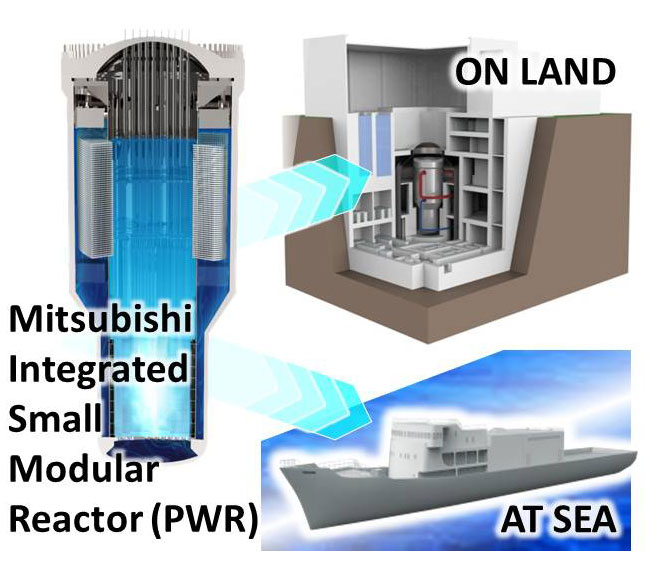

SMR Development for Small Grit Power Reactors and Mobile Reactors

Mitsubishi Heavy Industries, Ltd.

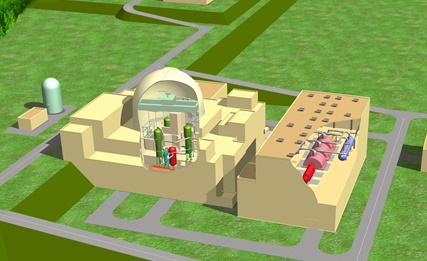

the next-generation light water reactor achieving the world's highest safety and economic efficiency

Mitsubishi Heavy Industries, Ltd.

Triple hybrid stand–alone power generation system

Mitsubishi Heavy Industries, Ltd.

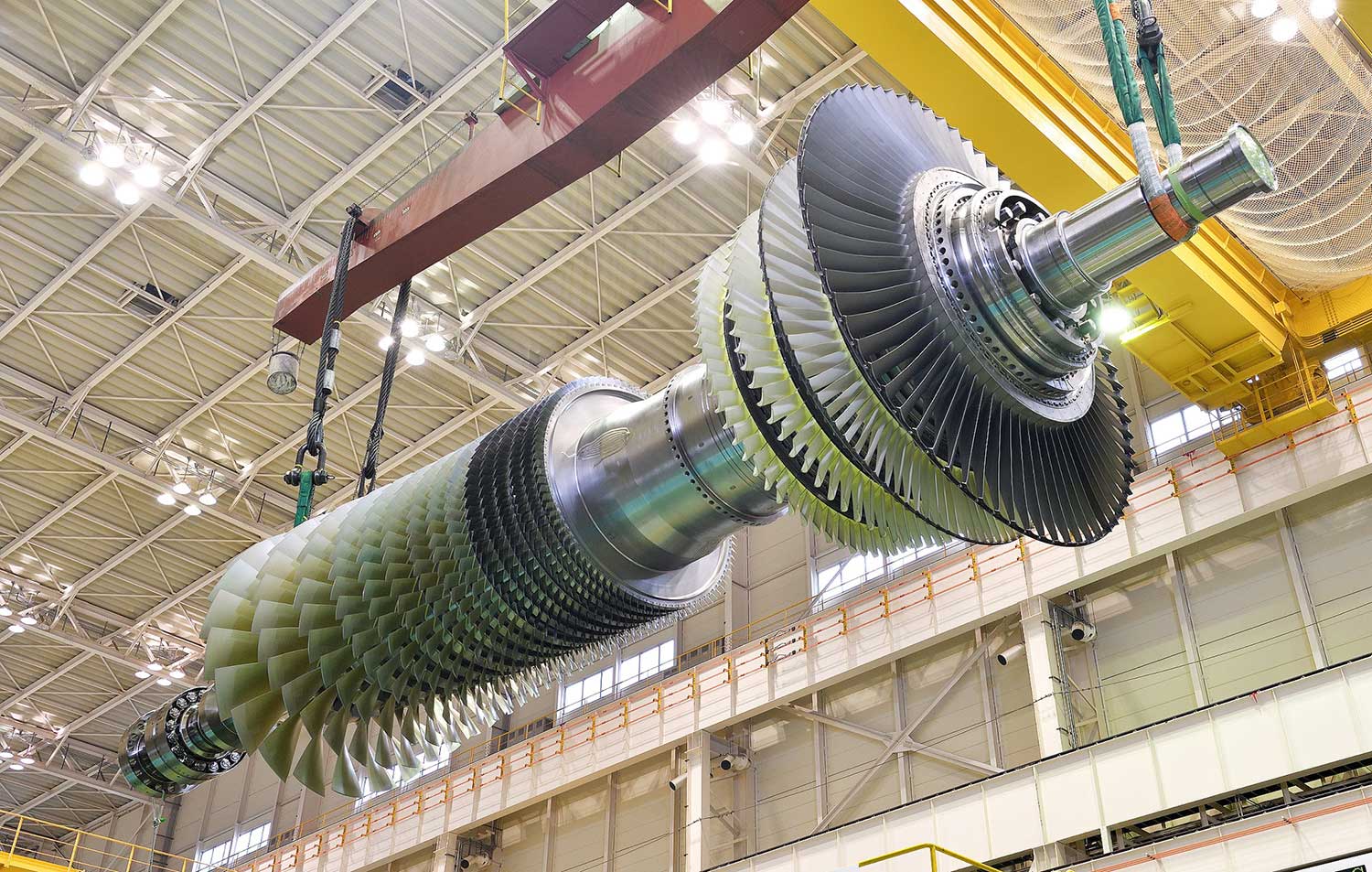

World's most efficient large GTCC power plant

Mitsubishi Heavy Industries, Ltd.

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)