Promotion of centrifugal chillers using low-GWP refrigerant across full capacity range

Mitsubishi Heavy Industries, Ltd.

Outline

MHI Group is leading the industry by establishing a product line-up of centrifugal chillers using low-GWP refrigerant across full capacity range. It is our intention to promote the accelerated introduction of them to the market and in the extent contribute to the reduction of exhaust of the greenhouse effect gases at the “transitional” stage.

Description

1. Background

Until recently, it was dominant to use the HFC-134a, which has relatively high GWP of 1300 (GWP: Global Warming Potential, where CO2 has index as 1), as the refrigerant of centrifugal chillers. The situation changed in 2016, when Kigali Amendment to the Montreal Protocol has reached agreement, and by law established in Japan, a milestone was set to terminate the production of equipment using higher GWP refrigerant. (*1)

(*1) Japanese related law requires every air-conditioning equipment manufacturers to bring down their weighted average GWP to 100 or below by year 2025 each, where currently products widely available are relying on refrigerants with GWP ranging from 675 to 2000s.

2. Target to Achieve

MHI Group will strive to encourage the promotion of such low-GWP refrigerant centrifugal chillers in the market. To be specific, although it will become automatically virtually impossible to sell centrifugal chillers using HFC-134a under related legislations in Japan after 2025, we estimate the market penetration by the low-GWP chillers will be as low as around 50% by 2023 if we leave the market as it goes.

Our target is to enhance this penetration ratio to 75% by then.

3. Quantitative contribution when the target is achieved

Presuming all the centrifugal chillers operating in Japanese domestic market will be replaced with our low-GWP refrigerant units, the environmental impact by emission of refrigerants, a kind of green-house effect gas, in the air will be reduced by 99.94% from 8,296 thousand ton-CO2 per year (*2) to around 6 thousand ton-CO2 a year.

In addition to the above, as the new units will require 40% less energy for operation compared to the existing units they are going to replace, a further reduction of 168 thousand ton-CO2 could be expected.

(*2) Source : METI, Japan.

4. Challenges to achieve the target

The new centrifugal chiller with low-GWP refrigerant costs 10 to 40 per cent more compared to the established models, depending on its capacity.

5. Actions to take

There are group of users who explicitly declare the commitment and responsibility to preserving the environment and such companies are gradually becoming early adopters of our low-GWP centrifugal chillers. It is our priority to achieve the cost-effectiveness of the new units to exceed the expectations of such customers, and to entrench our position in the market before the majority of users start to explore the low-GWP chiller options.

Partner(s)

Mitsubishi Heavy Industries Thermal Systems, Ltd.

Supplementary information

ETI-Z (Low GWP Refrigerant) :

http://www.mhi-mth.co.jp/en/products/detail/centrifugal_chiller_introduction.html

Other Innovation Challenges

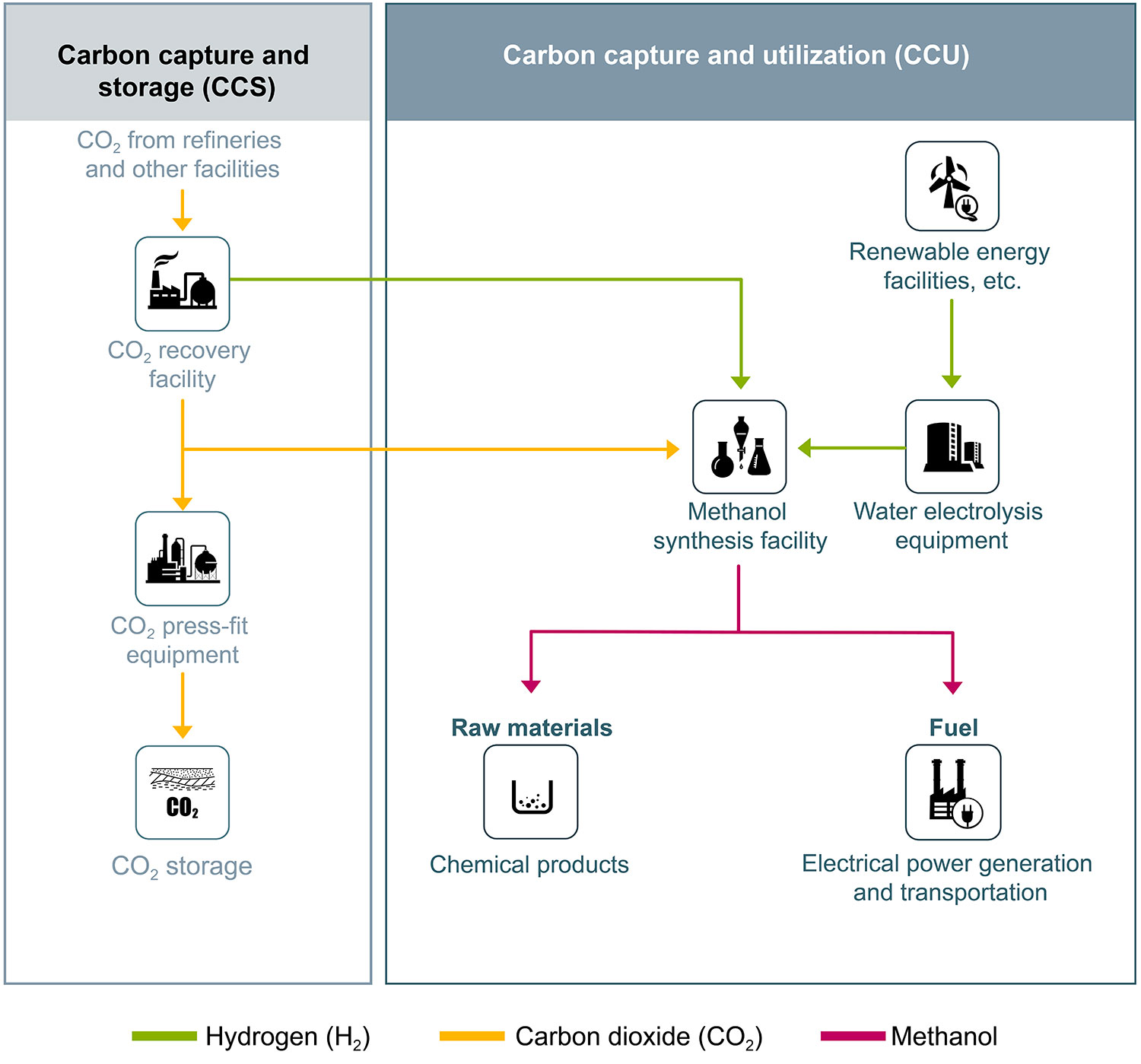

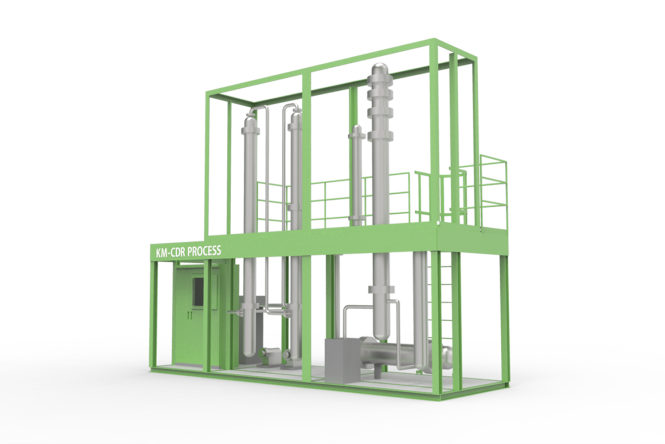

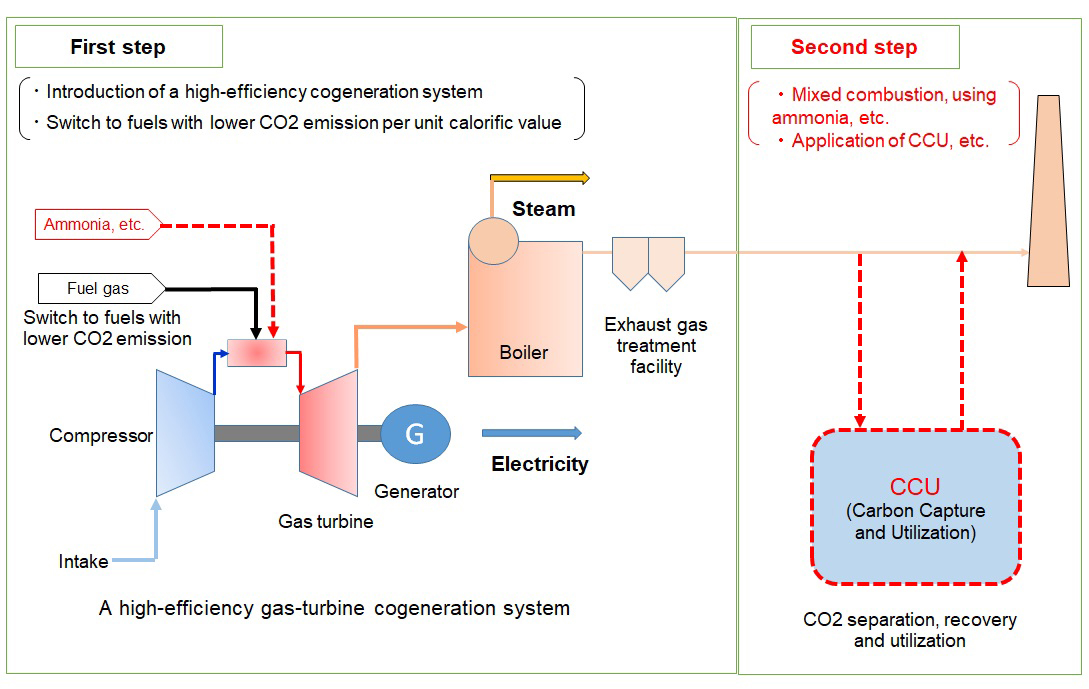

Commercialization of “carbon neutral” and “carbon negative” by implementing carbon capture technology

Mitsubishi Heavy Industries, Ltd.

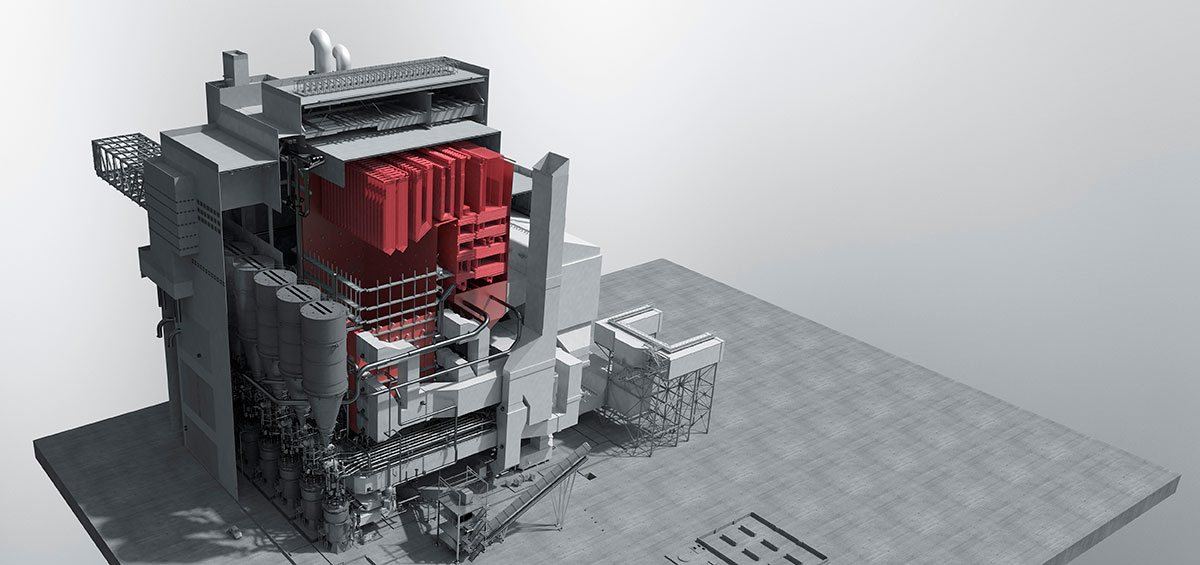

Decarbonization technology of Waste to Energy Facilities

Mitsubishi Heavy Industries, Ltd.

Dissemination of Low-Carbon Stable Energy Infrastructure Based on IGCC Technology

Mitsubishi Heavy Industries, Ltd.

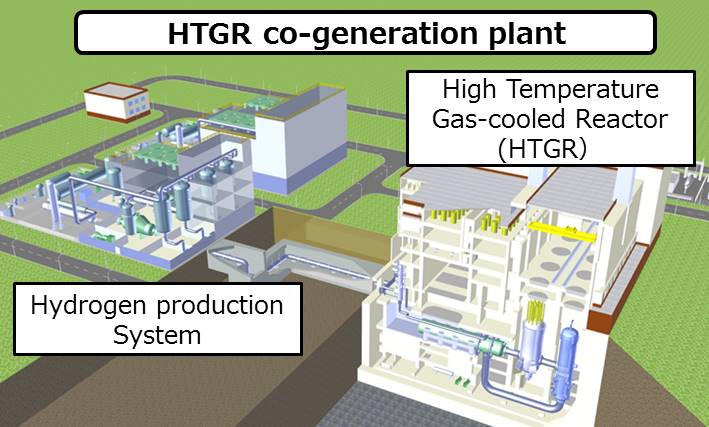

High-Temperature Gas-cooled Reactor co-generation for hydrogen production

Mitsubishi Heavy Industries, Ltd.

QoEnTM approach – A Quantitative Index to suggest the direction toward High-quality Energy Infrastructure

Mitsubishi Heavy Industries, Ltd.

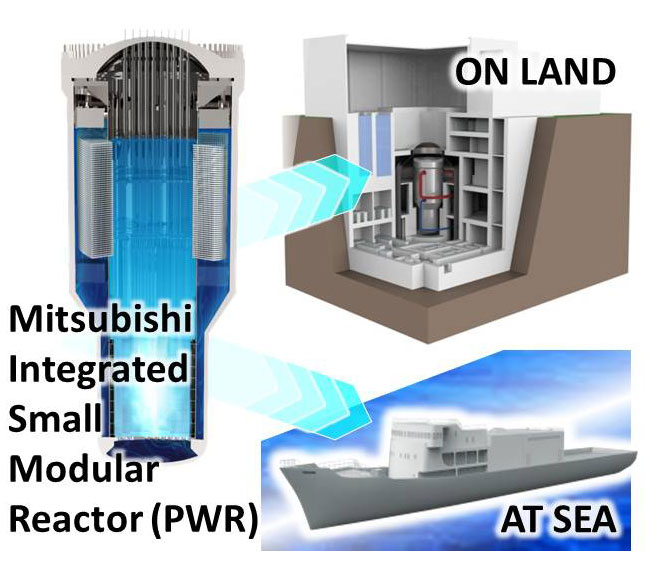

SMR Development for Small Grit Power Reactors and Mobile Reactors

Mitsubishi Heavy Industries, Ltd.

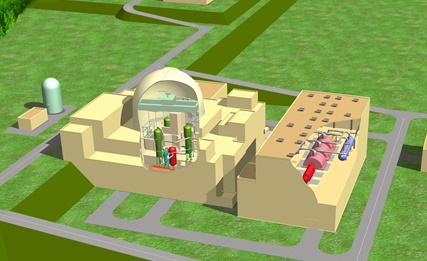

the next-generation light water reactor achieving the world's highest safety and economic efficiency

Mitsubishi Heavy Industries, Ltd.

Triple hybrid stand–alone power generation system

Mitsubishi Heavy Industries, Ltd.

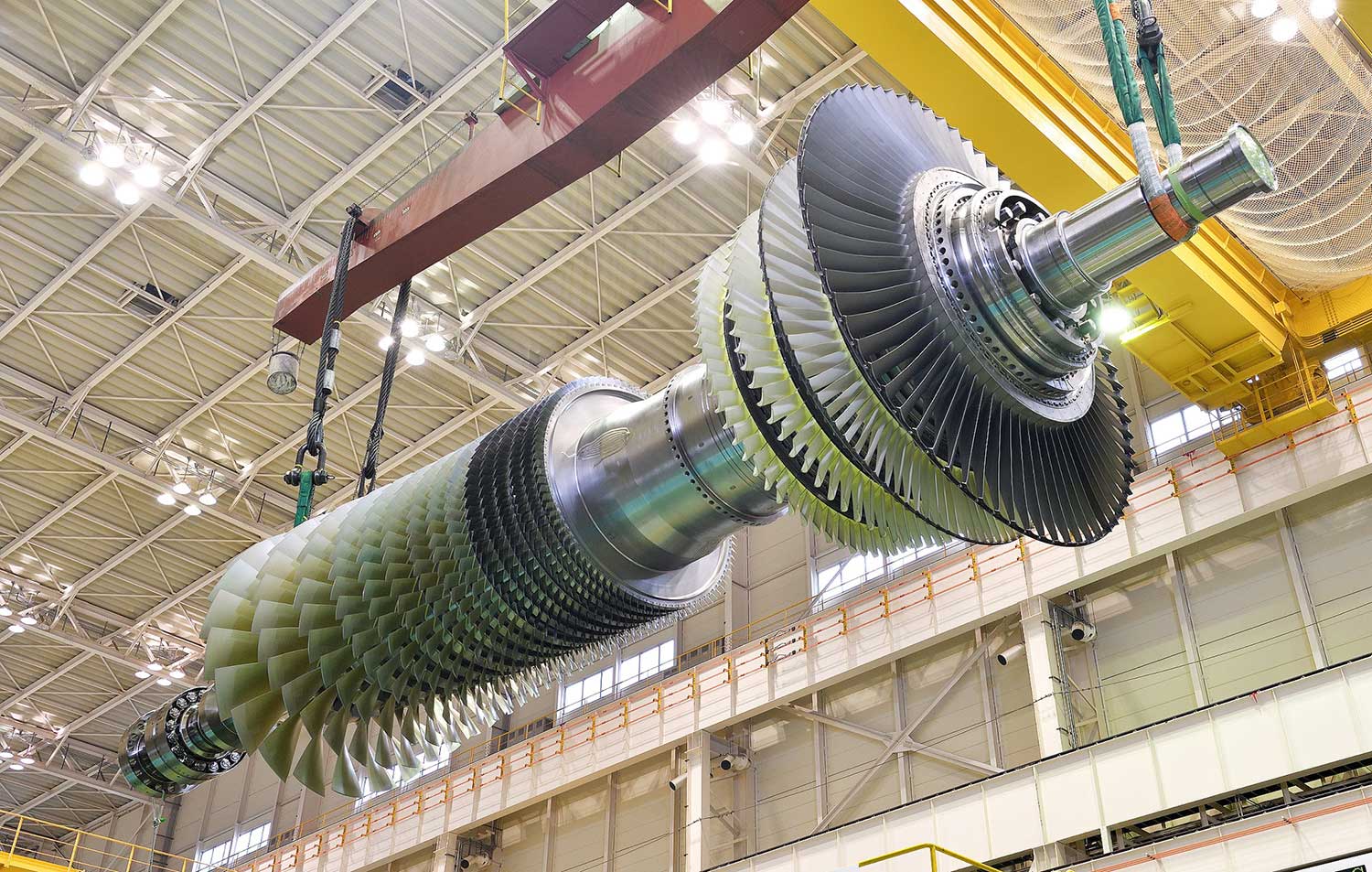

World's most efficient large GTCC power plant

Mitsubishi Heavy Industries, Ltd.

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

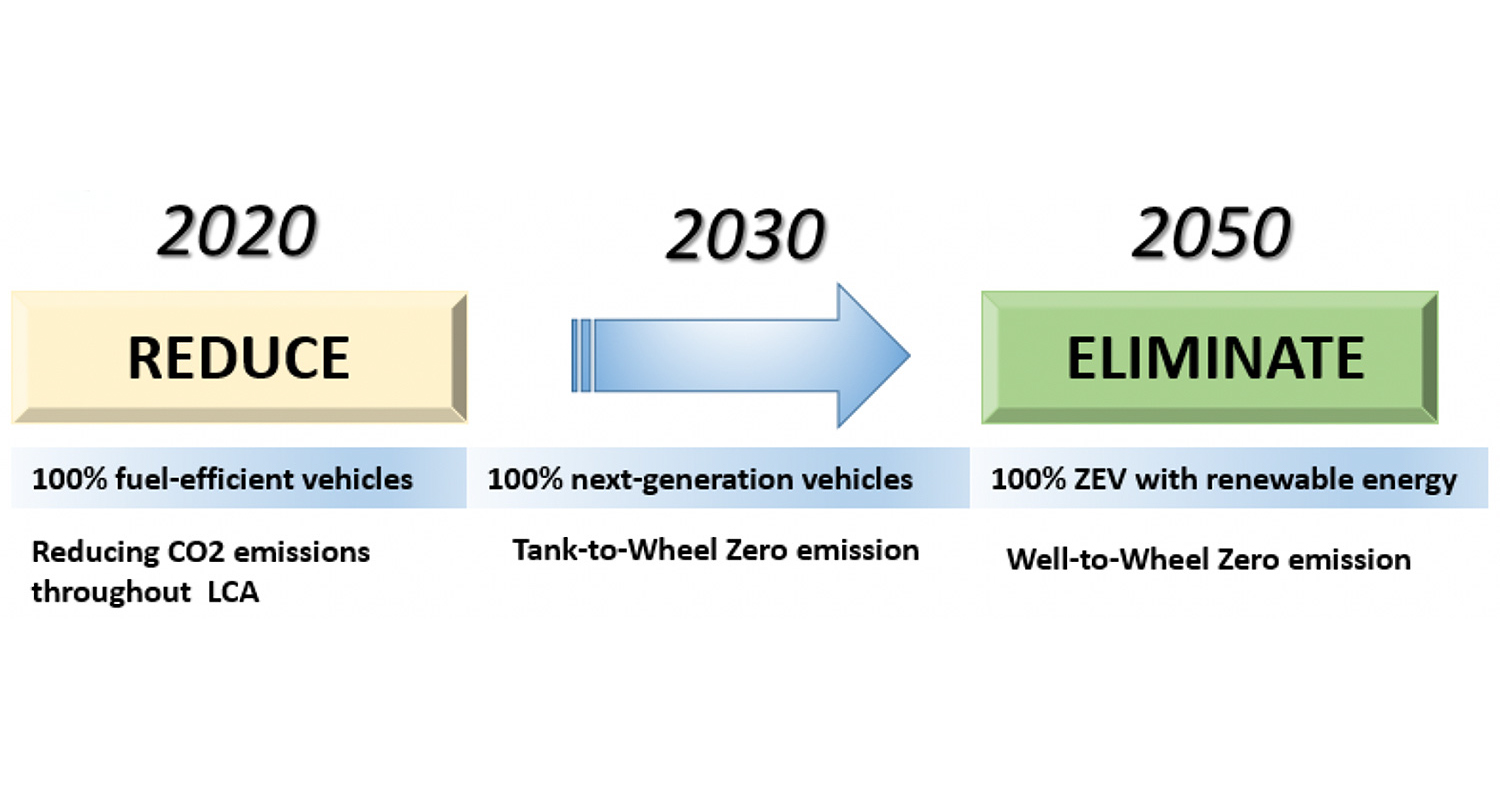

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.