Development of Hydrogen Steelmaking Process for Zero Emission

NIPPON STEEL CORPORATION

Outline

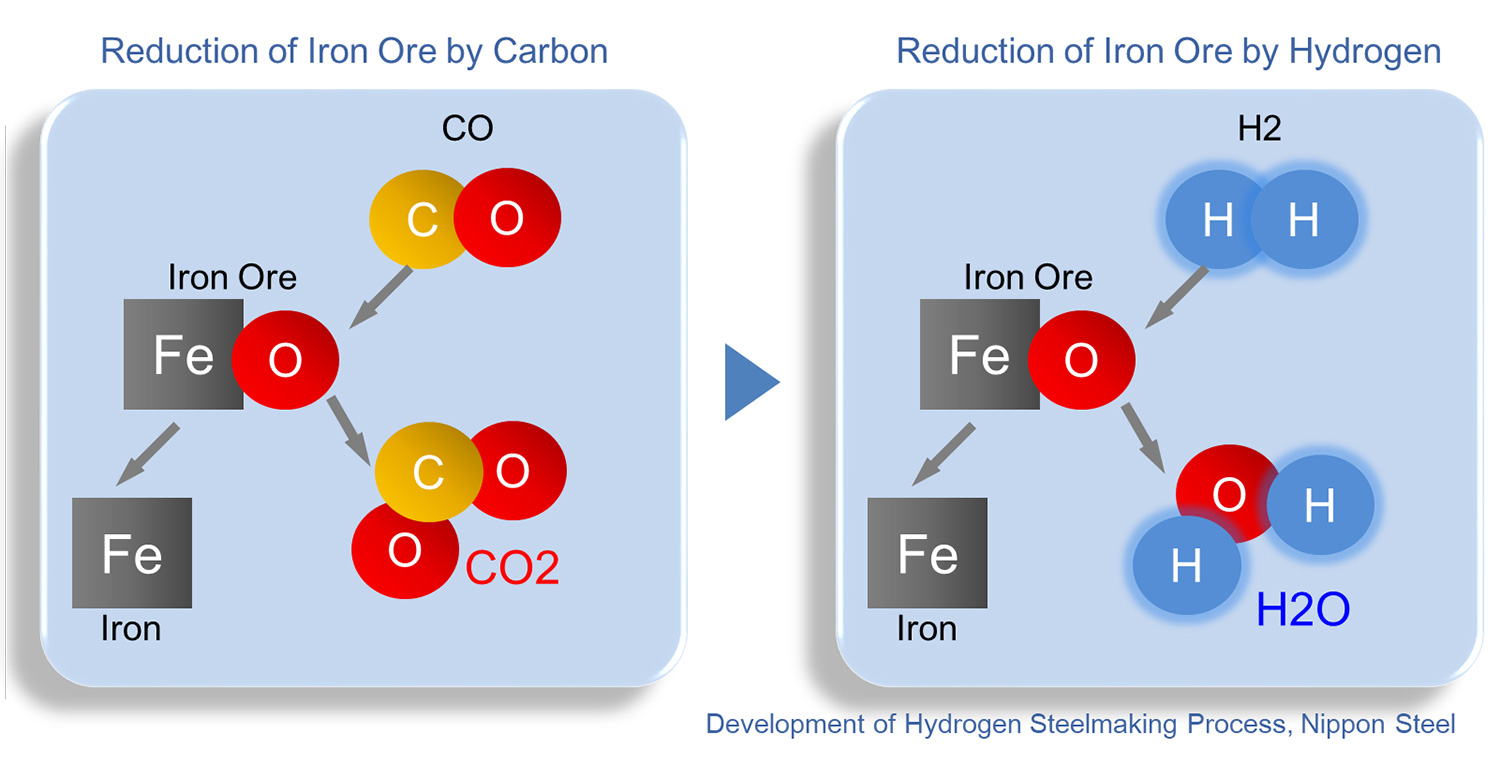

The steel industry accounts for about 9% of global CO2 emissions, and improving the energy efficiency of the steel industry's manufacturing processes is crucial for sustainable resource use and the preservation of the global environment. In this theme, in order to achieve net zero emissions in the steelmaking process, we will challenge the technology development of hydrogen reduction ironmaking technology, in which iron ore will be reduced by hydrogen as a reducing agent instead of coking coal.

Description

a) Achievement goal in challenge

We will establish a technology to reduce iron ore with 100% hydrogen, which does not use coal (carbon) and therefore does not emit CO2 at all.

b) Challenges to be overcome to realize the challenge

· About 70% of the CO2 emitted by the steel industry is generated in the process of pig iron production using blast furnaces (reduction reaction that removes oxygen from iron ore, which is iron oxide, to iron). Pig iron production in Japan's blast furnace technology has improved to near thermodynamic theoretical values, making further reduction of CO2 very difficult.

· Since the hydrogen reduction reaction of iron ore is an endothermic reaction, it is necessary to establish a technology to supply heat to the reactor from the outside and a technology to stably supply a large amount of hydrogen-based gas to the reactor in consideration of the combustion characteristics of hydrogen.

· The current blast furnace and converter method is extremely excellent in scale, productivity, raw material handling ability, cost competitiveness, and product quality, and requires the development of super-innovative technology to replace it. It is also important to consider the various conditions of the Japanese steel industry, such as restrictions on raw material procurement.

c) Nippon Steel’s strengths and specific actions

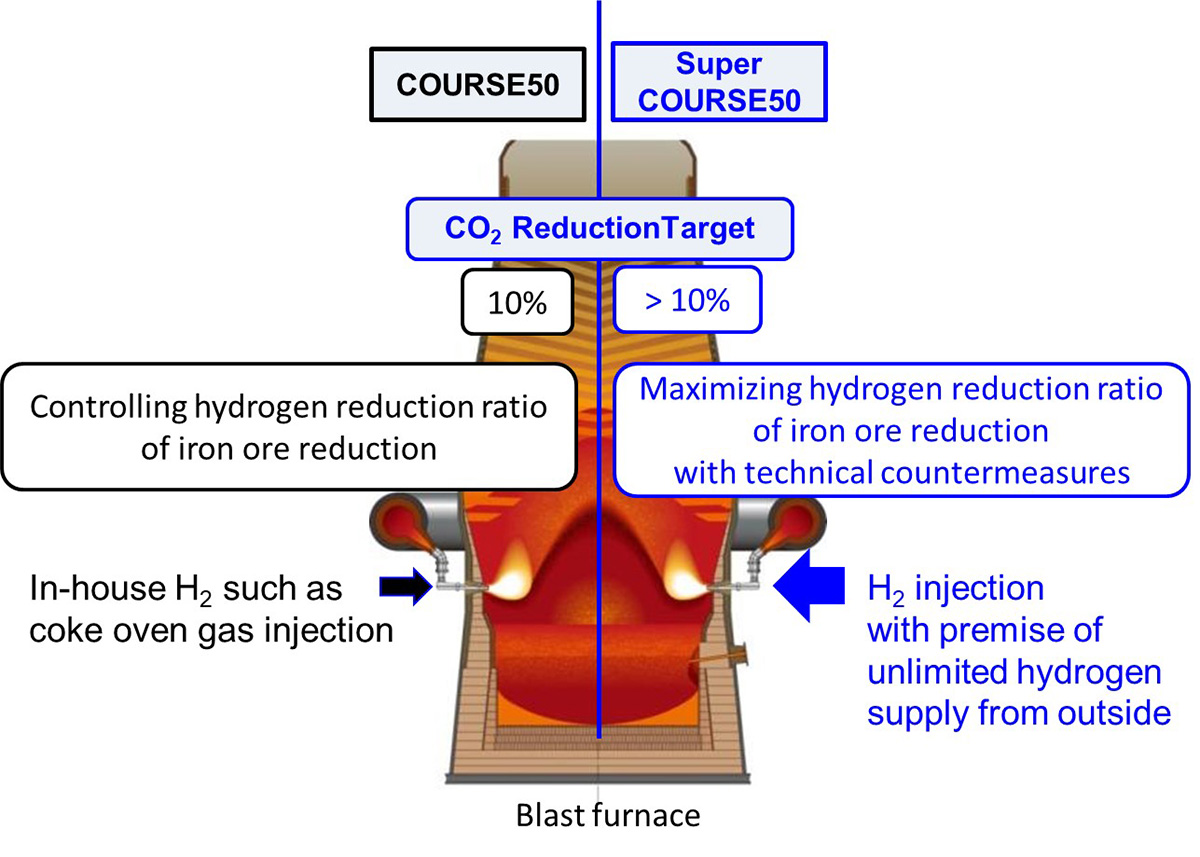

· In the national project called COURSE50 (CO2, Ultimate Reduction in System for Cool Earth 50), technology development of the blast furnace itself that replaces part of the reduction reaction in the blast furnace using hydrogen-based gas with hydrogen reduction (CO2 emission 10 % Reduction) since 2008, and has the advantage of accumulating knowledge and elemental technologies of hydrogen reduction steelmaking.

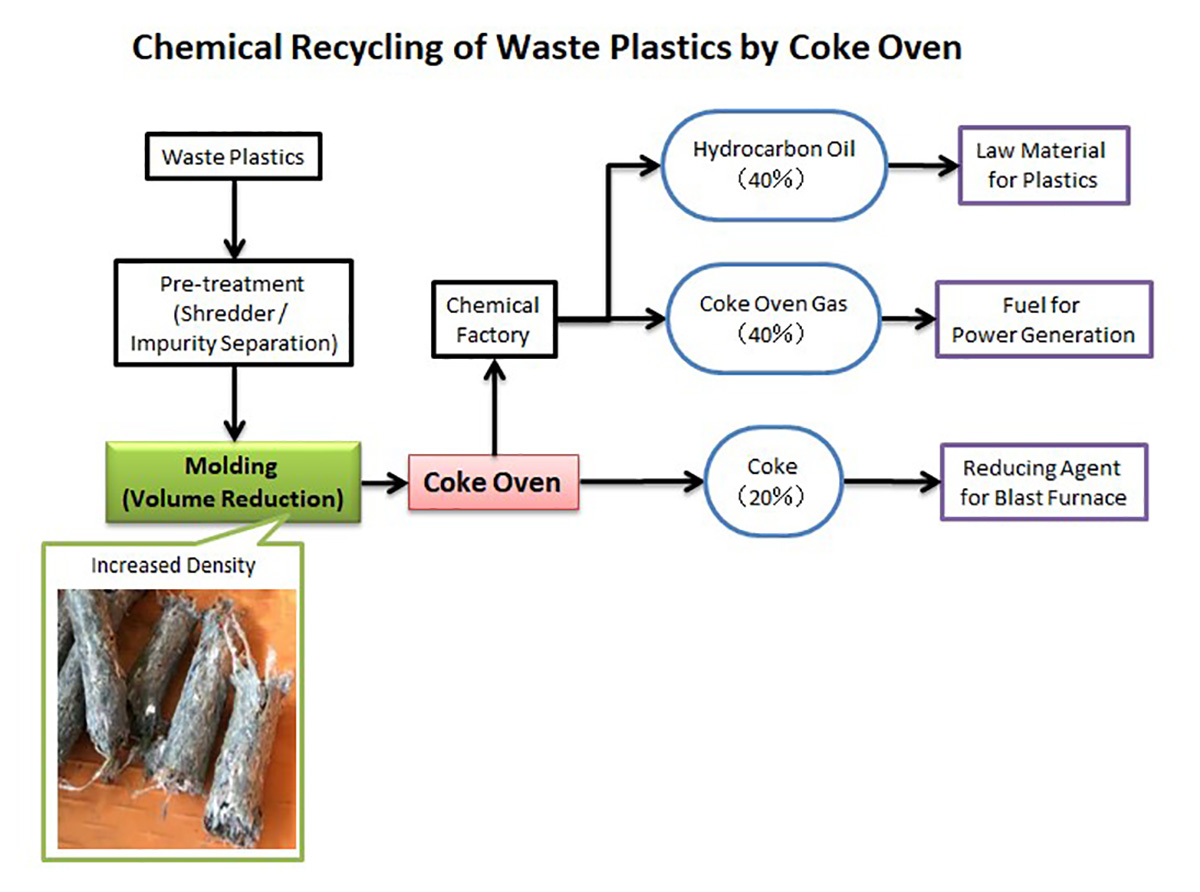

· The existing methods of iron ore reduction using gas, shaft reduction furnaces, and fluidized bed reduction furnaces are candidates for consideration. Work on development on a zero basis, including methods.

· In this challenge, blast furnace manufacturers will cooperate in technological development under the Japan Iron and Steel Federation.

· Hydrogen used in hydrogen reduction steelmaking is widely used not only in steelmaking but also in various sectors such as automobiles and households, so it is premised that it is developed and maintained as an energy carrier based on a common social infrastructure. In particular, hydrogen used in the production of steel is not only carbon-free, but also requires a large and inexpensive and stable supply. Therefore, we will work in cooperation with the government and industry.

d) Quantitative effects of realizing the challenge

· Mass supply of steel materials is our mission from the perspective of the SDGs. We will pursue to achieve zero emissions in domestic steel production and further disseminate the technology worldwide.

Partner(s)

Ministry of Economy, Trade and Industry (METI), Japan Iron and Steel Federation, JFE Steel Corporation, Kobe Steel, Ltd.,

Supplementary information

JISF long-term vision for climate change mitigation

https://www.jisf.or.jp/en/activity/climate/index.html

Other Innovation Challenges

CO2 uptake and carbon storage as blue carbon by utilizing steel slag

NIPPON STEEL CORPORATION

Contributing the hydrogen infrastructure formation by spreading usage of the specialized steel for hydrogen station

NIPPON STEEL CORPORATION

Development and dissemination of Eco ProductsTM that contribute to reductions in CO2 emissions at the point of product use

NIPPON STEEL CORPORATION

Development of CO2 emission reduction technology using hydrogen in blast furnace steelmaking

NIPPON STEEL CORPORATION

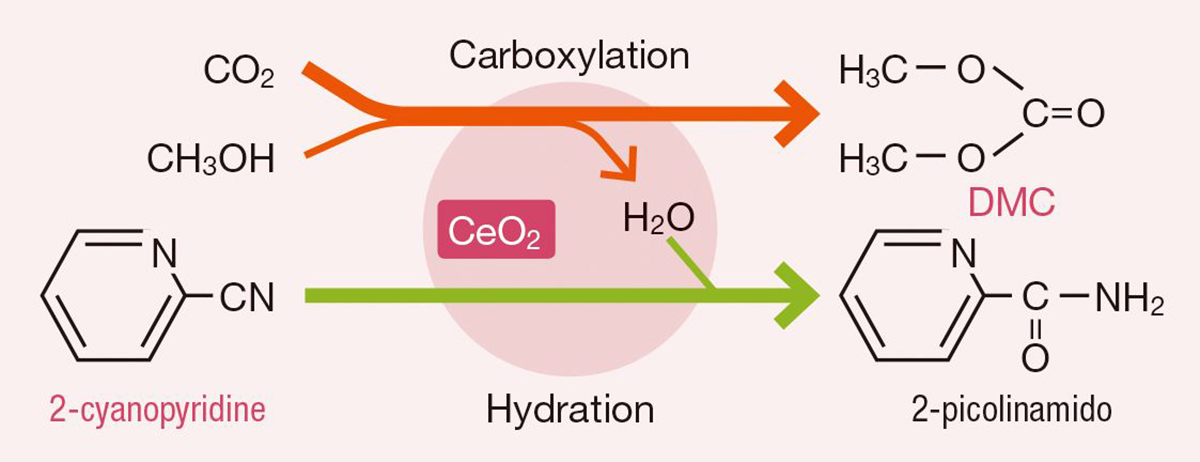

Establishment of dimethyl carbonate (DMC) production method using CO2 as raw material

NIPPON STEEL CORPORATION

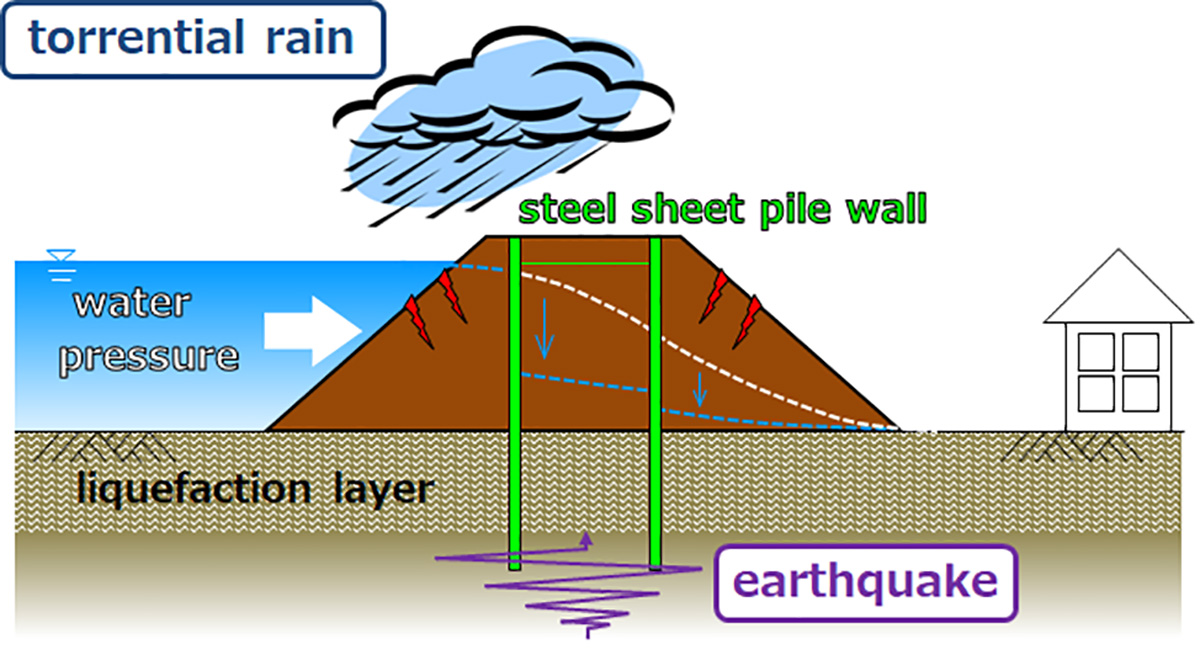

Provision of solutions for “National Resilience” aimed at adaptation to climate change

NIPPON STEEL CORPORATION

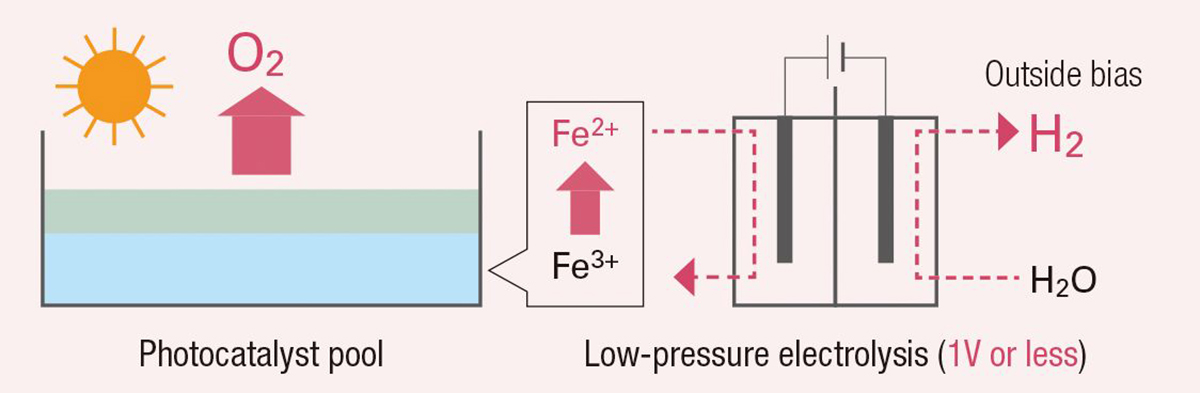

Zero emission hydrogen production technology by artificial photosynthesis

NIPPON STEEL CORPORATION

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION