Challenge for development of super‐innovative technologies focusing on “Carbon‐recycling Blast Furnace+CCU”

JFE Holdings, Inc.

Outline

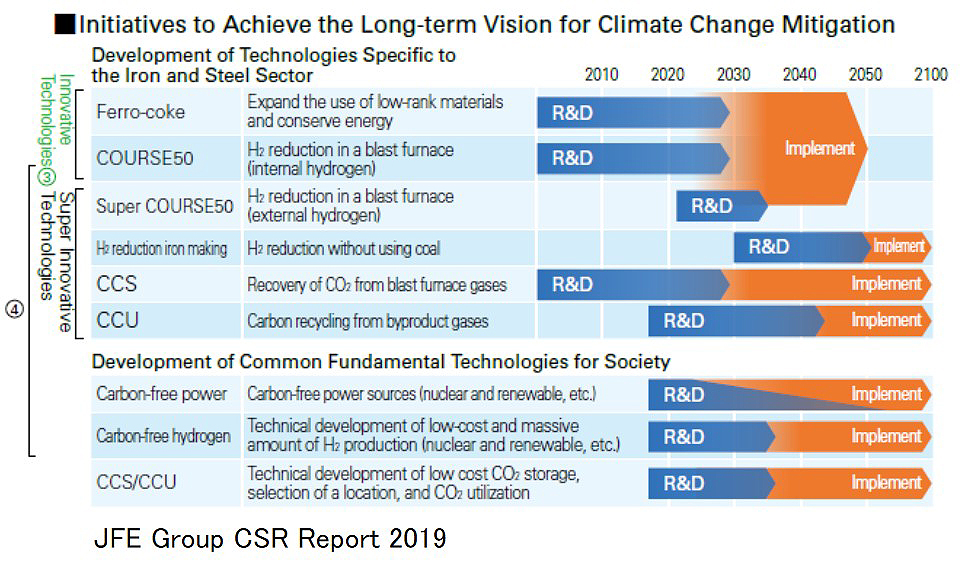

JFE group regards climate change is an extremely important issue from the perspective of business continuity, global climate-change issues, such as increasingly abnormal weather, must be addressed urgently. Therefore, based on our corporate philosophy of contributing to society with the world's most innovative technology, JFE group will accelerate our research and development of new technologies and pursue super-innovative technologies to combat climate change and to achieve carbon neutrality in 2050. In addition to addressing our business risks, we will seek business opportunities that allow us to help realize a more sustainable world and enhance our corporate value by contributing to CO₂ emissions reduction across society.

Description

Current practicable steelmaking processes have advantages and disadvantages that require multi-track technological development. The most world popular blast furnace process has many advantages such as stable mass production, or being able to manufacture high-grade steel, still it has disadvantages such as emission of CO₂ during reduction of iron ore. JFE steel will adopt multi-track approach to develop super-innovative technologies, focusing on carbon recycling blast furnace (CRBF)+CCU and hydrogen ironmaking (direct reduction) and maximize utilization of industry-leading electric arc furnace technology.

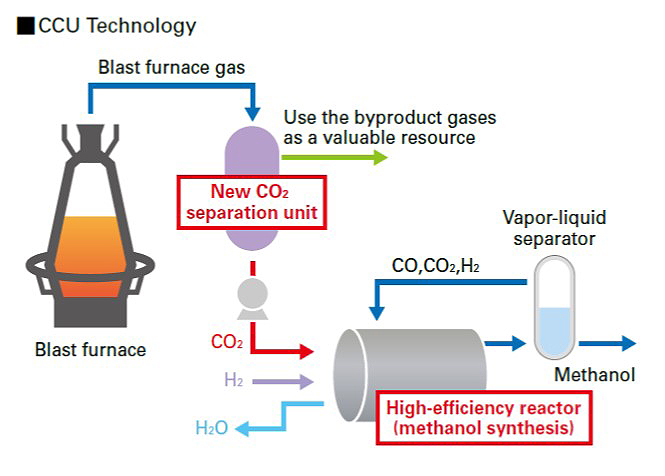

CRBF is an innovative process to replace coal origin reducing agent for blast furnace with methane (carbon-neutral methane) transformed (methanation reaction) from steel work off-gas with green hydrogen using renewable energy. That means CO₂ generated from blast furnace is converted to methane and used repeatedly as reducing material. Surplus CO₂ is reduced by being transformed into basic chemical product such as methanol.

The oxygen blast furnace can maximize the amount of blasting carbon-neutral methane volume, because combustion heat which is necessary for heating nitrogen gas in the conventional BF can be applied to heating methane instead by blasting 100% oxygen and methane. Developing an all-new technology to reduce CO₂ emissions by blasting large amount of carbon-neutral methane with oxygen is the world's first challenge.

And zeroing out nitrogen in blast furnace gas reduces amount of exhaust gas by about half, and increasing CO₂ concentration enables CO₂ separation process to be downsized since less energy is required. Interlock operation with large-scale methanation facilities is another world's first as well.

Application in CRBF with CCU for CO₂ emissions reduction currently is jointly being developed by JFE and Research Institute of Innovative Technology for the Earth (RITE). New type of reactor for CCU methanol synthesis uses steel works exhaust gas to produce methanol significantly lower cost compared to conventional reactors.

We will conduct elemental technology development and small-scale testing for both CRBF and CCU methanol synthesis, targeting completion of proof-of-principle process by 2027.

Elemental technology developments for CRBF are; (1) Develop simulation model, (2) Design operations and facility (furnace shape, etc.) based on analysis of in-furnace phenomena (gas flow and temperature distribution), (3) Maximize combustion efficiency through pure oxygen methane burner combustion experiments and (4)Develop optimum methanation technology adapting BF off-gas. And a large-volume city gas blasting test at Keihin No.2 blast furnace before shutdown will be conducted as a partial demonstration of CRBF.

CCU elemental technologies developments are (1) Develop low-cost CO₂ separation technology for CCU, and (2) Develop high efficiency methanol synthesis reactor. Then, basic designs as (1) Conduct CO₂ separation lab tests to evaluate CO₂ separation efficiency and determine operation method, and (2) Conduct methanol synthesis lab tests to evaluate reaction rate and simulate reaction rate maximization will be carried out.

Partner(s)

Research Institute of Innovative Technology for the Earth (RITE)

Supplementary information

“JFE Group Environmental Vision for 2050”

https://www.jfe-holdings.co.jp/investor/management/plan/index.html#20210525

“RITE Inorganic Membranes Research Center”

https://www.rite.or.jp/membranes/

Other Innovation Challenges

Multi-site integrated energy network services for energy saving

JFE Holdings, Inc.

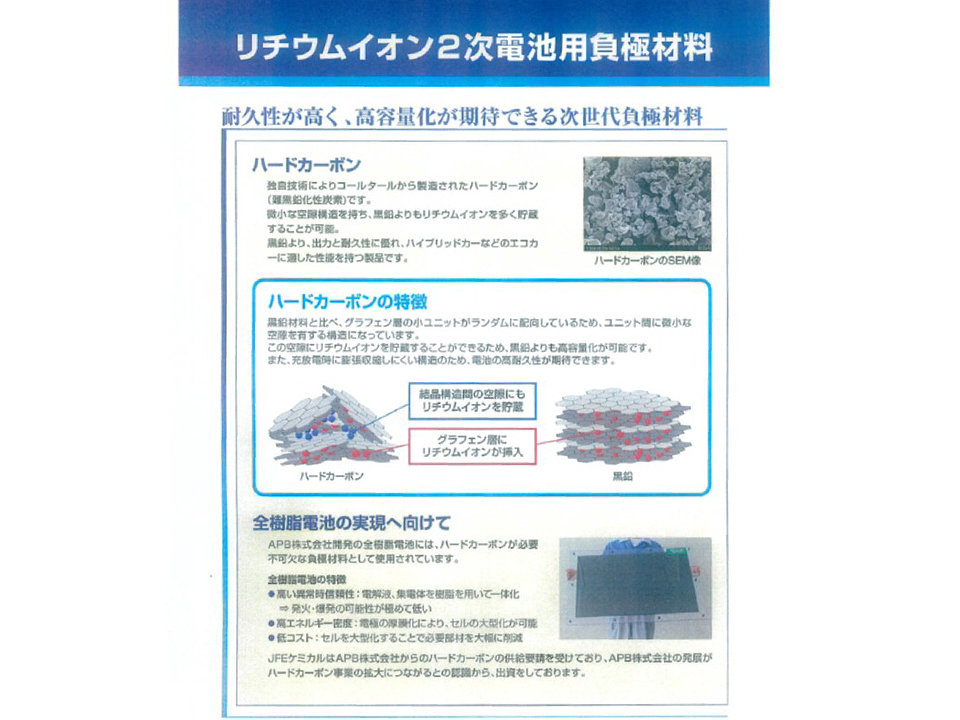

Realization of decarbonization by developing hard carbon for next-generation lithium-ion battery "All-polymer battery"

JFE Holdings, Inc.

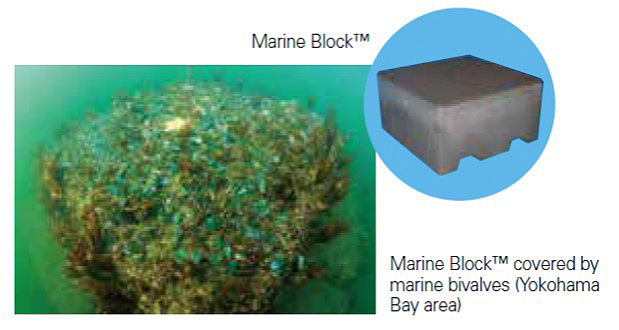

Technology of improving water quality of sea area by use of steel slag products

JFE Holdings, Inc.

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION

.png?id=2&tid=812&imageNumber=1)