Technology of CO2 utilization

JFE Holdings, Inc.

Outline

【JFE Steel Corporation】

JFE Steel Corporation has been promoted NEDO*1 project*2. JFE Steel Corporation is working on an initiative together with RITE*3 to develop new technologies for separating and recovering CO2 from blast furnace gas and utilizing.

*1 New Energy and Industrial Technology Development Organization

*2 “Development of next-generation thermal power generation technologies / Development of basic technologies for next-generation thermal power generation / Development of CO2 utilization technology”

*3 Research Institute of Innovative Technology for the Earth

Description

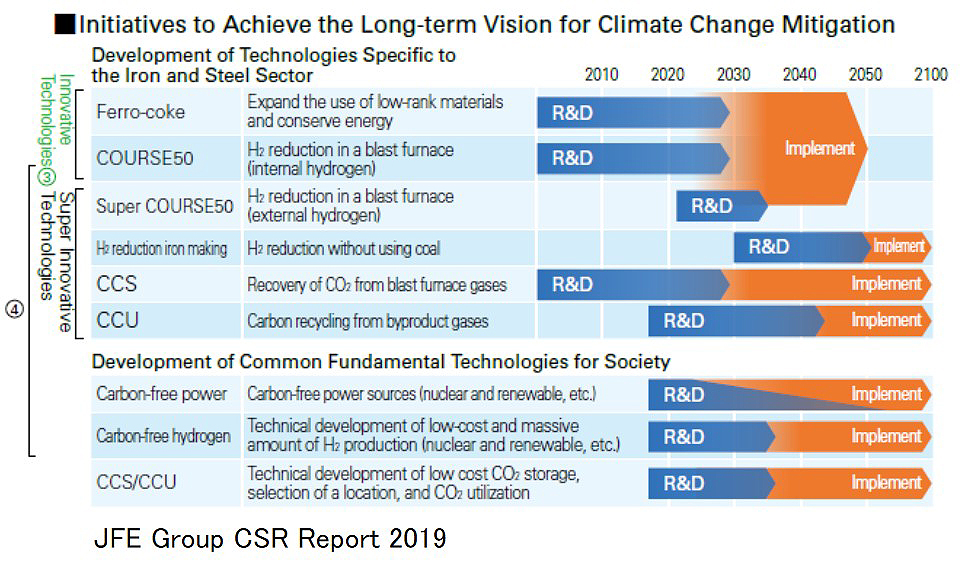

In order to reduce CO2 emissions from the steel manufacturing process, JFE Steel Corporation is actively engaged in the development of new technologies to separate and recover CO2 from blast furnace gas. This is in line with the JISF’s COURSE50 project (CO2 Ultimate Reduction System for Cool Earth 50), which focuses on hydrogen reduction of iron ore and separation and recovering of CO2 from blast furnace gas. JFE Steel Corporation has been working on developing for practical use a physical adsorption technology for separating and capturing CO2, which could then be fed to carbon capture and storage (CCS).

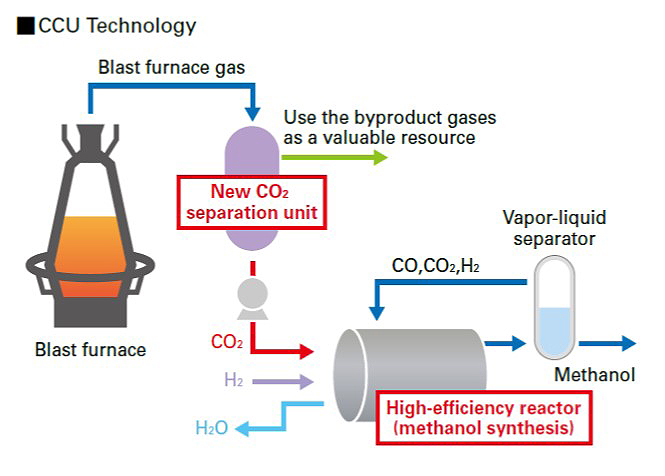

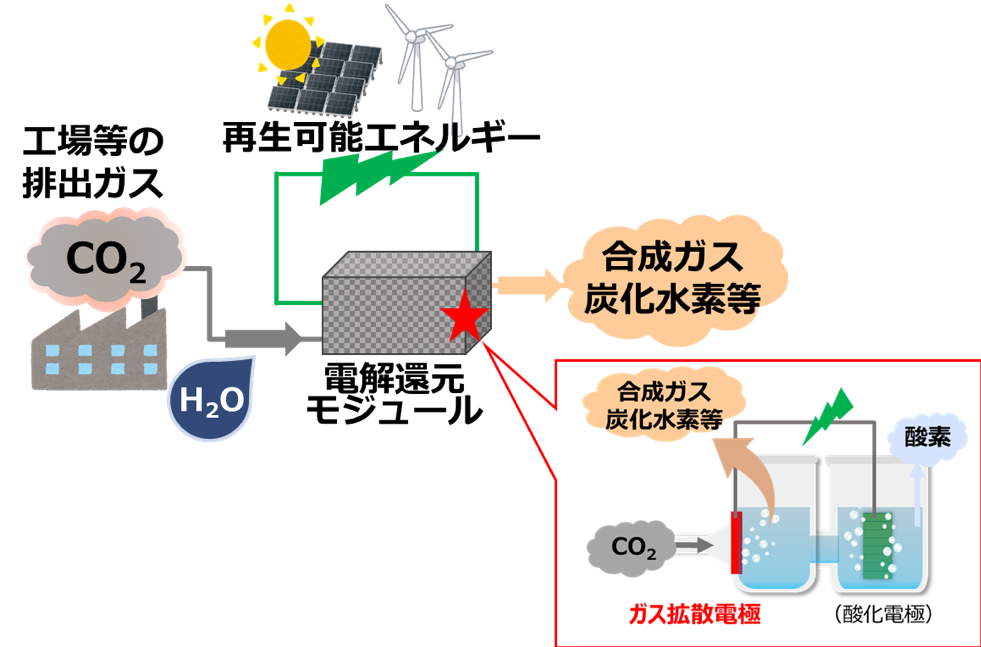

More recently, JFE Steel Corporation has also initiated R&D into the effective use of CO2 separated and recovered from blast furnace gas and is one of the first domestic steel manufacturers to explore this field. JFE Steel Corporation is a participating member of NEDO projects for the development of next-generation thermal power generation technologies / development of basic technologies for next-generation thermal power generation / development of CO2 utilization technology project, and as such, it is working on an initiative together with RITE to develop new technologies for separating and recovering CO2 from blast furnace gas and utilizing it to synthesize methanol (CH3OH).

In this project, JFE Steel Corporation is developing technologies that lower the cost of CO2 separation and recovery that meets the objectives of CCU and process design for effective CO2 utilization. The expertise in CO2 separation and recovery technologies it has acquired through the COURSE50 project is applied to CCU.

Technical overviews are as follow;

- PSA technology has a cost advantage for CCU which does not require high-purity CO2 gas.

- Methanol was chosen as a target product and a membrane as a reactor. The reasons are methanol is an initial material of chemicals which market is large, and high reaction rate exceeded equilibrium can be obtained with a membrane reactor.

Technical targets of the project are as follow;

- Investigation of CO2 transformation/utilization technologies projected to save energy and cut cost by CCU adaptation.

- Overall optimization study of energy-saving type CCU process from CO2 emission source and CO2 recovery to transformation process.

- Planning of process concept through small evaluation tests with chosen promising technologies*.

* chosen promising technologies are PSA technology as a CO2 separation, and production of methanol as a transformation process (CCU).

- JFE Steel Corporation will extract technological development subjects to be solved and will clarify implementation scenarios through planning research and development for practical application of promising systems.

Expected effects are as follow;

- Reduction of CO2 emission for 1 ton of methanol production is 2ton.

- To continue research and development for practical application. JFE Steel Corporation will investigate partnership or scheme of business toward practical application of CCU using CO2 in emitted gas as material from steel work.

Partner(s)

The Institute of Applied Energy, RITE (Research Institute of Innovative Technology for the Earth), INPEX Corporation and Hitachi Zosen Corporation

Other Innovation Challenges

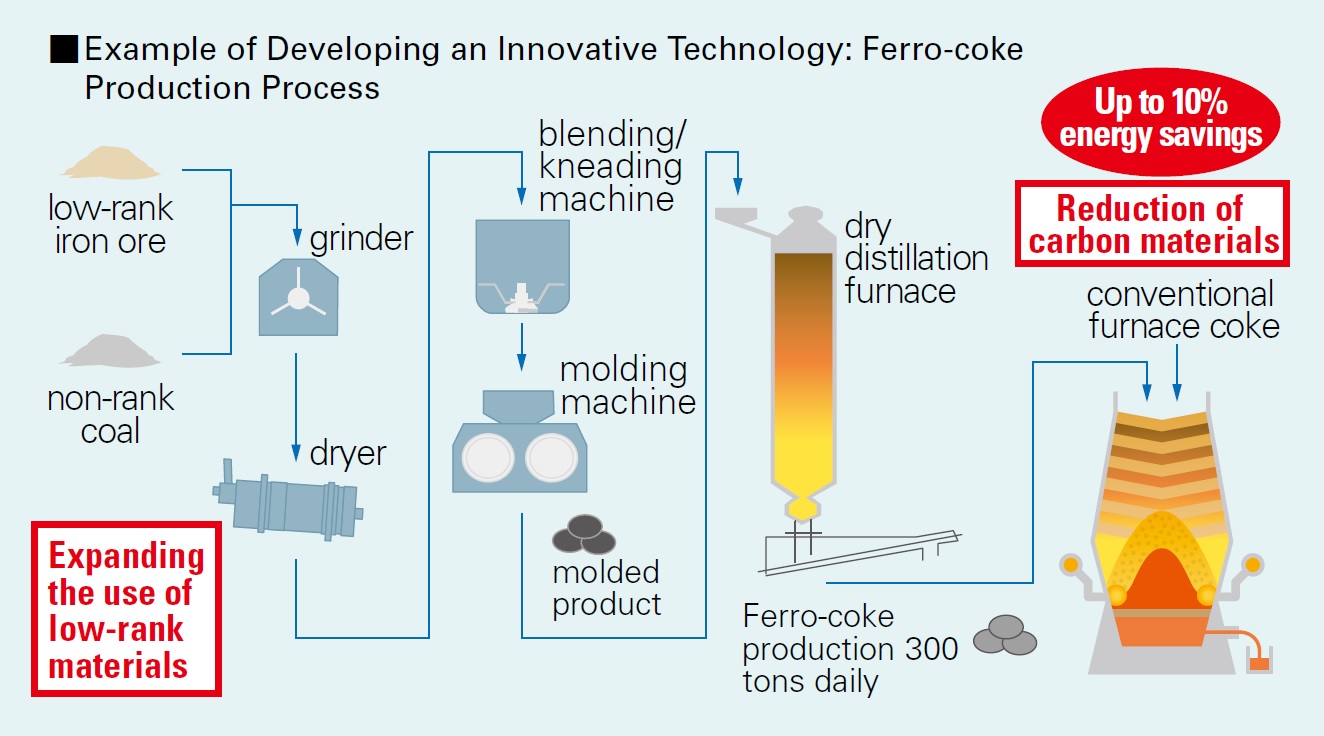

Challenge for development of super‐innovative technologies focusing on “Carbon‐recycling Blast Furnace+CCU”

JFE Holdings, Inc.

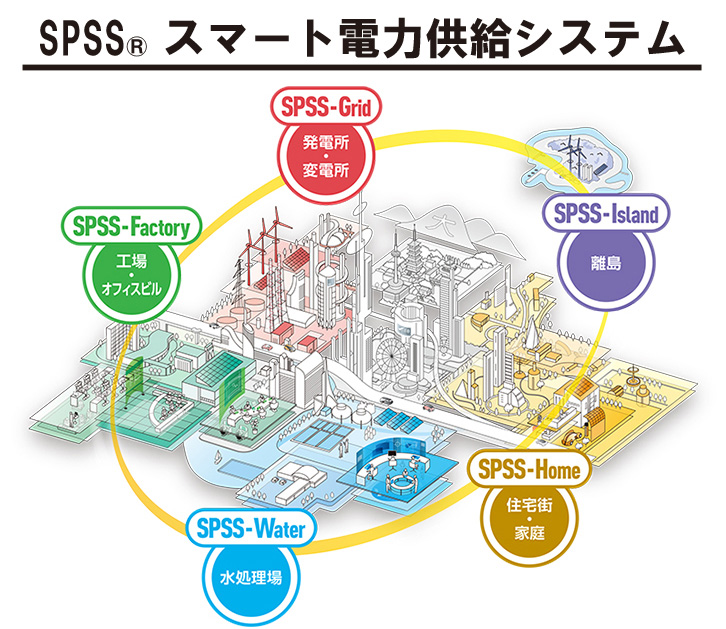

Multi-site integrated energy network services for energy saving

JFE Holdings, Inc.

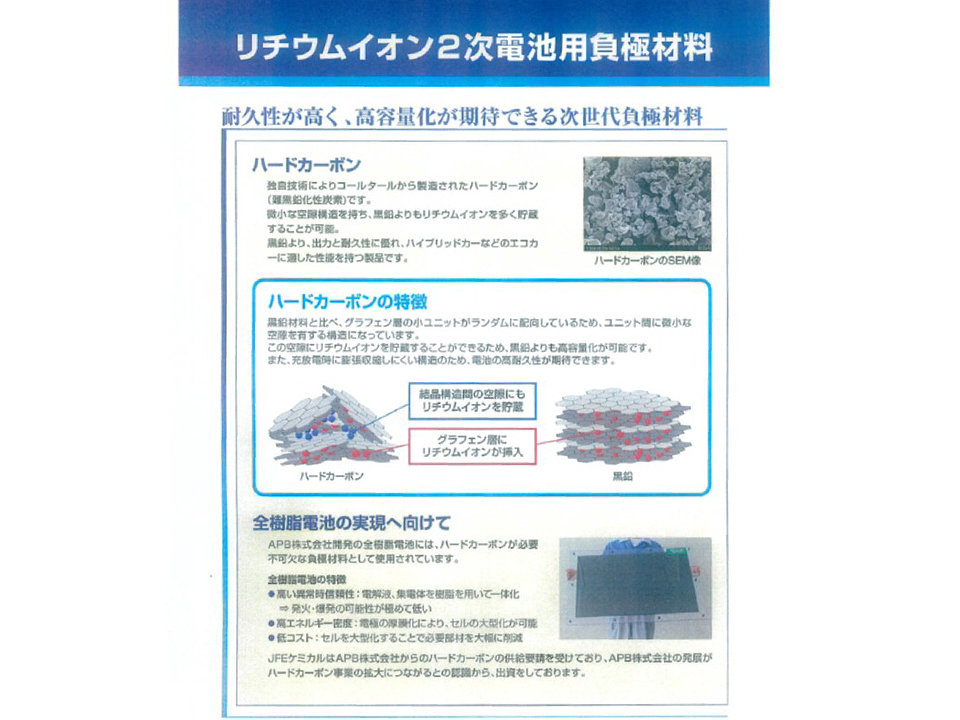

Realization of decarbonization by developing hard carbon for next-generation lithium-ion battery "All-polymer battery"

JFE Holdings, Inc.

Technology of improving water quality of sea area by use of steel slag products

JFE Holdings, Inc.

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

.png?id=2&tid=812&imageNumber=1)

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)