Construction and operation of hydrogen stations and development of hydrogen usage technology for the sake of building hydrogen supply chains

Toho Gas Co., Ltd.

Outline

Together with moving forward on the construction and operation of hydrogen stations for the sake of decarbonization in the mobility field, we are anticipating the building of hydrogen supply chains and working on the development of hydrogen combustion technology in industrial fields. We will contribute to the attainment of net zero carbon in multiple fields through the use of hydrogen.

Description

【Construction and Operation of Hydrogen Stations】

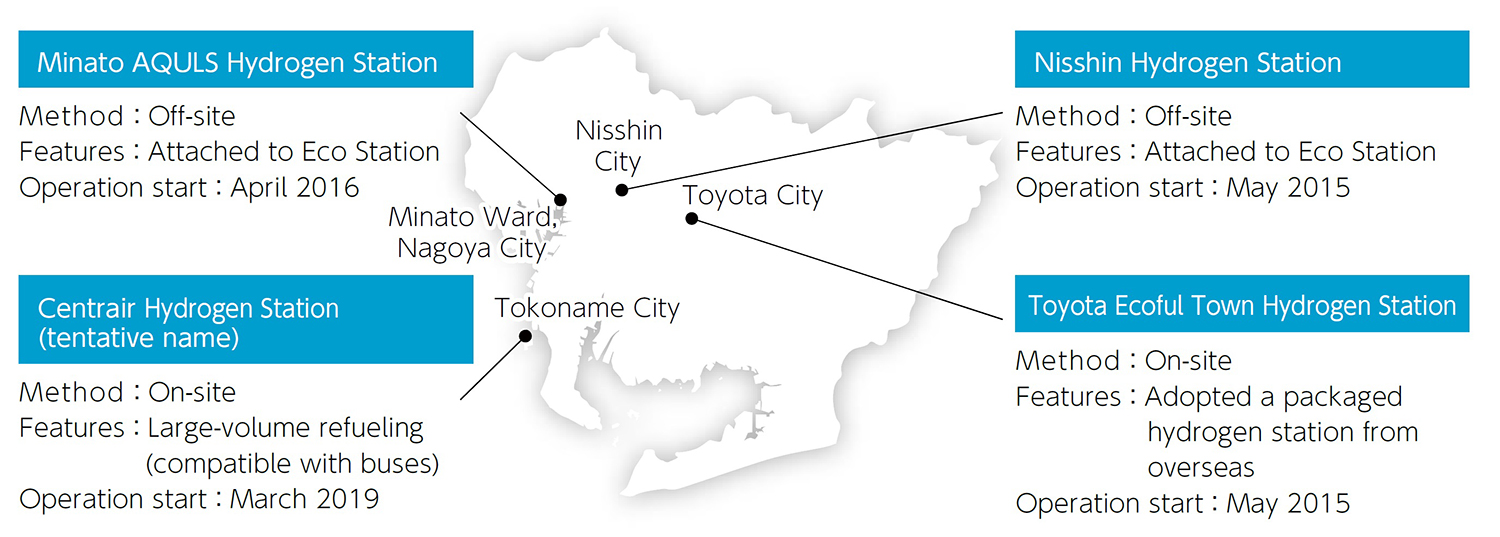

We have been working on constructing and operating four hydrogen stations. We are currently building a fifth hydrogen station, with completion target by the end of 2020. On the other hand, we have linked up with various relevant parties, including the national and local governments, hydrogen station operators and builders, and automobile manufacturers, and are tackling station construction and operation cost reduction through study of hydrogen station equipment and system standardization, regulation review, etc. We will continue these activities and contribute to the spread of fuel cell automobiles and the attainment of net zero carbon.

【Development of Hydrogen Usage Technology】

We are working on the development of hydrogen usage technology in industrial fields. Concretely, we are identifying and starting to work on technical issues for the use of hydrogen in entire industrial furnaces from the burners to the distribution pipes. For example, compared to city gas whose main component is methane, hydrogen has high combustion speeds and high flame temperatures, so measures are required against flashback and other combustion instability, against increased NOx emissions, against higher burner nozzle temperatures, etc. Also, because hydrogen flames are difficult to check with the naked eye, measures are necessary to make flame detection reliable. Measures are also necessary against leaks in the distribution pipes to the burners. In order to resolve such technical issues, we will work on developing technology for optimizing burner nozzle structure and combustion control, studying the application of solenoid valves and other auxiliary pipe equipment to hydrogen distribution pipes, developing new technology of them, and so on. And moving forward to practical viability in a wide range of heating processes, we will contribute to the attainment of net zero carbon.

Supplementary information

Toho Gas Group Integrated Report 2019

https://www.tohogas.co.jp/lang/en/corporate/document/annual/pdf/2019toho_tougou_en.pdf

Other Innovation Challenges

Development of high-density heat storage technology that contributes to the effective use of heat energy

Toho Gas Co., Ltd.

Establishment of both advanced energy management and enhanced resilience for the sake of spreading renewable energy and distributed power sources

Toho Gas Co., Ltd.

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION