Technical Development and Popularization of Efficient CO2-Use Concrete

The Chugoku Electric Power Company, Incorporated

Outline

We have been working on the technical development and popularization of environmentally friendly concrete that provides efficient use of CO2 (product name: CO2-SUICOM). This concrete is produced by using special materials/methods that can absorb CO2 from various emission sources (such as thermal power stations). Additionally, materials with low CO2 emissions (such as coal ash and blast furnace slag) are used as much as possible so that, together with the CO2 absorption amount, CO2 emissions can be substantially reduced to zero or less. As one type of carbon recycling technology contributing to the realization of a carbon-free society, we are working on reducing the cost of this environmentally friendly concrete and to expand the applicable products in order to further popularize and expand its usage.

Description

We have been working on the technical development and popularization of environmentally friendly concrete that provides efficient use of CO2 (product name: CO2-SUICOM (CO2-Storage and Utilization to Infrastructure by Concrete Materials)).

This concrete includes a special admixture that absorbs CO2 as it hardens. During the production process, the concrete is placed in a curing tank before it has hardened, and CO2 is drawn into the curing tank to be absorbed by the concrete as it hardens. This allows CO2 from various emission sources, such as that emitted by thermal power stations, to be efficiently used.

Due to the special admixture of CO2-SUICOM that absorbs CO2 as the concrete hardens, the amount of cement used is greatly reduced in addition to CO2 absorption. Although with regular concrete blocks, approximately 300 kg of CO2 is emitted from the materials used per 1 m3 of concrete, industrial byproducts with low CO2 emissions (such as coal ash and blast furnace slag) are used in CO2-SUICOM as much as possible so that, together with CO2 absorption, CO2 emissions (from materials used) can be substantially reduced to zero or less. Once absorbed, the CO2 undergoes a chemical reaction to harden inside the concrete so that CO2 cannot be desorbed from the concrete after production.

CO2-SUICOM can be made as strong as regular concrete. Additionally, the excellent wear-resistance and low efflorescence allow plants to readily thrive, a positive feature not provided by regular concrete.

This new concrete is mainly being used currently for pre-cast concrete products such as road and pavement blocks that are factory-produced. Various products are already actually being used. Although some of the products are used for long periods, the durability is completely equal to regular concrete products.

However, the special materials and methods included in the production process results in a higher cost in comparison with regular concrete products. Moreover, it is currently difficult to apply to products containing reinforced steel and cast-in-place concrete.

As one type of carbon recycling technology contributing to the realization of a carbon-free society, we will continue technical development to reduce the cost and expand the range of applicable products in order to further increase its use.

(Division of roles for each company)

The Chugoku Electric Power Co., Inc.: Production verification testing (Thermal power stations)

Kajima Corp.: Product development and design

Denka Co., Ltd.: Special admixture development

Landes Co., Ltd.: Production and sales of pre-cast products

Mitsubishi Corp.: Business development and marketing

Partner(s)

Kajima Corp., Denka Corp., Landes Corp., Mitsubishi Corp.

Supplementary information

https://www.energia.co.jp/assets/press/2010/p110113-1.pdf

https://www.energia.co.jp/press/2014/771.html

https://www.energia.co.jp/press/2014/717.html

(Press release materials related to CO2-SUICOM on the Chugoku Electric Power website)

Other Innovation Challenges

Demonstration and development of the ultimate high-efficiency coal-fired power generation (IGFC)

The Chugoku Electric Power Company, Incorporated

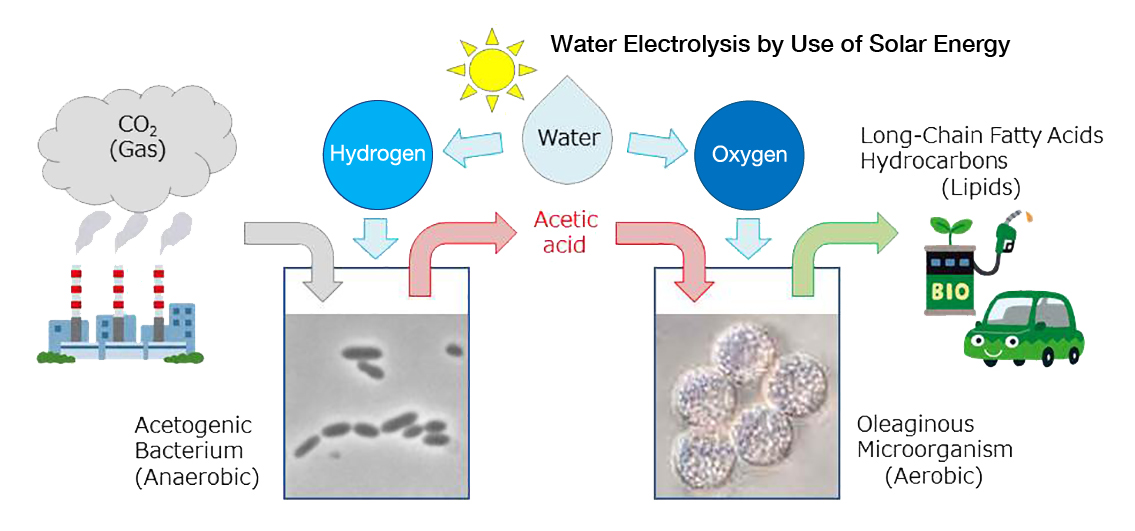

Development of a novel bioprocess to recycle CO2

The Chugoku Electric Power Company, Incorporated

Reusing Coal Ash as Civil Engineering Material Through CO₂ Absorbing Technology Using Microwave Irradiation

The Chugoku Electric Power Company, Incorporated

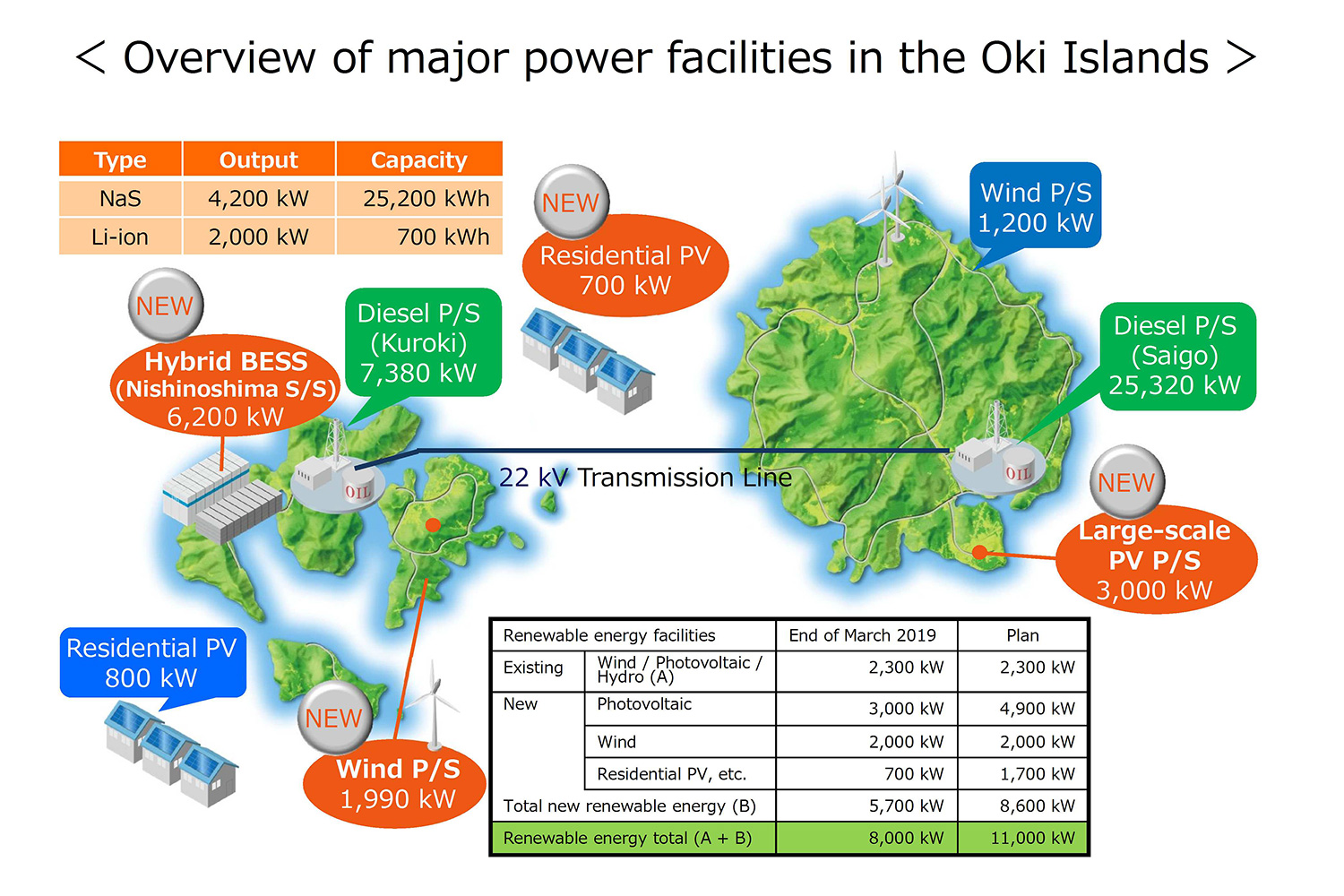

The Installation of a Hybrid Battery for Expansion of Renewable Energy Introduction in Oki Islands

The Chugoku Electric Power Company, Incorporated

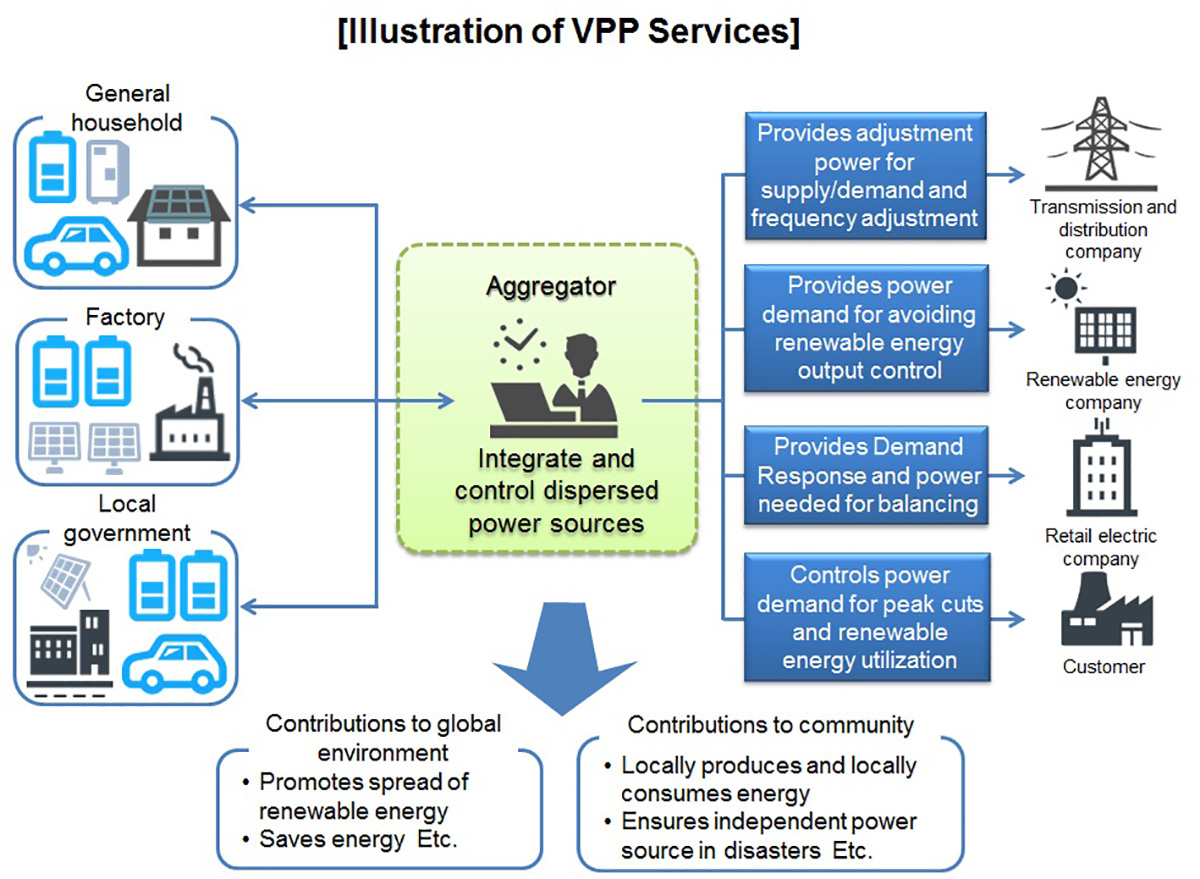

VPP Demonstration Project for Reuse Technology of EV Drive Batteries

The Chugoku Electric Power Company, Incorporated

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION