Development of a novel bioprocess to recycle CO2

The Chugoku Electric Power Company, Incorporated

Outline

With over 40% of Japanese energy/generated electricity is provided by coal and petroleum thermal power generation, the development of CO2 recycling technology is a pressing issue as CO2 accounts for the majority of greenhouse gases subject to reductions.

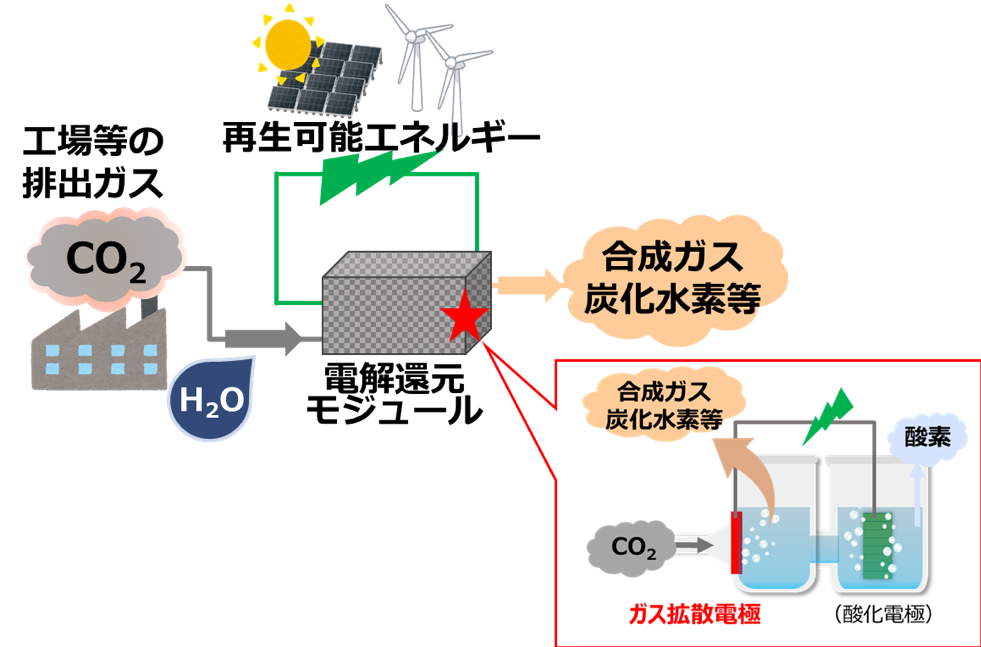

The goal of this project is to develop a novel bio-process capable of recycling CO2 by establishing a compound fermentation method that combines various micro-organisms capable of high-speed high-density culturing in a dark place to produce fats (lipids) used as fuels and chemical products from the exhaust gas of power generation.

Description

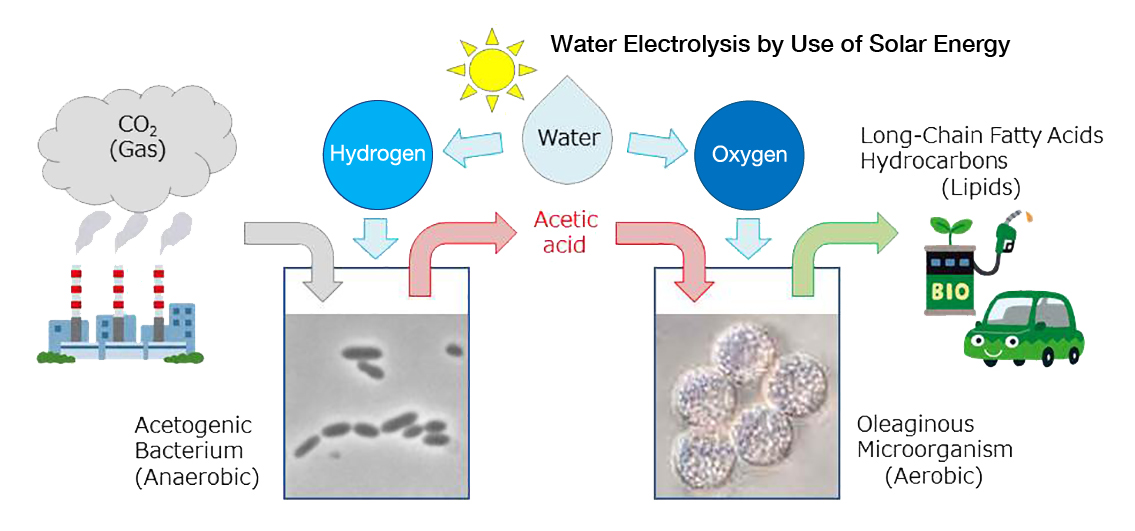

This technology is called a two-step fermentation system because it consists of fermenting two types of micro-organisms, Acetobacterium woodii and Aurantiochytrium, and called "Gas-to-Lipids" because it generates fats from CO2 (gas).

The first step of this two-step fermentation system uses Acetobacterium woodii to fix the CO2 emitted by thermal power stations and generate acetic acid. Acetobacterium woodii generates only acetic acid as a final product from the CO2 and hydrogen. This micro-organism is extremely promising as a CO2-fixing microbial catalyst due to the high CO2-to-acetic acid conversion rate.

Next, Aurantiochytrium is used in the second-step fermenter. The acetic acid generated in the first-step fermentation is supplied to the Aurantiochytrium culture tank so that Aurantiochytrium can use the acetic acid as a nutrient source to generate and accumulate useful lipids inside the cells of the Aurantiochytrium. These lipids can be used for fuels such as long-chain saturated fatty acids, polyunsaturated fatty acids and carotenoids, as well as for the raw materials of cosmetics, health foods, and other products.

In this way, the lipids that are final products of the second-step fermentation can be utilized as the raw materials for a wide variety of products including fuel, cosmetics, and health foods.

Issues and Concrete Actions to Overcome in Achieving the Challenge

・ Goal: To achieve acetic acid formation when the Acetobacterium woodii fermentation equipment is increased in scale.

・ Goal: To achieve lipids formation from the generated acetic acid by Aurantiochytrium fermentation.

・ Verification of the integrated production process construction of H2-CO2 supplied => Acetic acid produced => Fats/Oils produced.

* Specific values will be determined during research and development activities.

CO2 Reduction Effectiveness, etc.

・ If, for example, 400,000 tons of fuel oil were produced, it is predicted that the corresponding amount of recycled raw material CO2 could reach 1.12 million tons.

・ This technology is expected to be deployed all across the world as global standard technology if it can be applied to the exhaust gas from thermal power stations, which is rapidly increasing in countries such as China, by use of applied-international patents.

Partner(s)

Hiroshima University, Idemitsu Kosan Co., Ltd.

Supplementary information

Refer to p. 36 of "Example Cases of Carbon Recycling Technology" (Ministry of Economy, Trade and Industry)

https://www.enecho.meti.go.jp/category/others/carbon_recycling/tech_casebook/

Other Innovation Challenges

Demonstration and development of the ultimate high-efficiency coal-fired power generation (IGFC)

The Chugoku Electric Power Company, Incorporated

Reusing Coal Ash as Civil Engineering Material Through CO₂ Absorbing Technology Using Microwave Irradiation

The Chugoku Electric Power Company, Incorporated

Technical Development and Popularization of Efficient CO2-Use Concrete

The Chugoku Electric Power Company, Incorporated

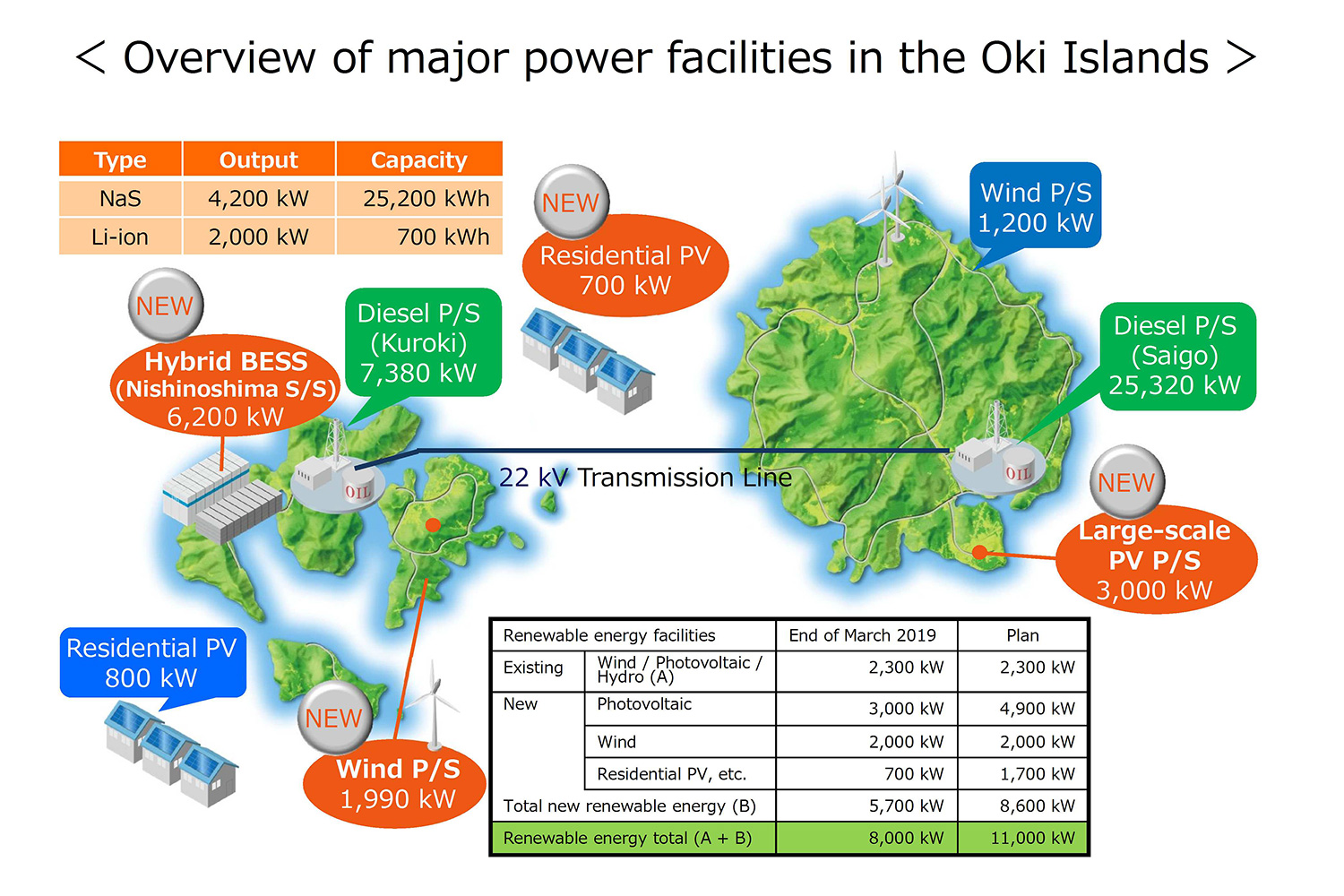

The Installation of a Hybrid Battery for Expansion of Renewable Energy Introduction in Oki Islands

The Chugoku Electric Power Company, Incorporated

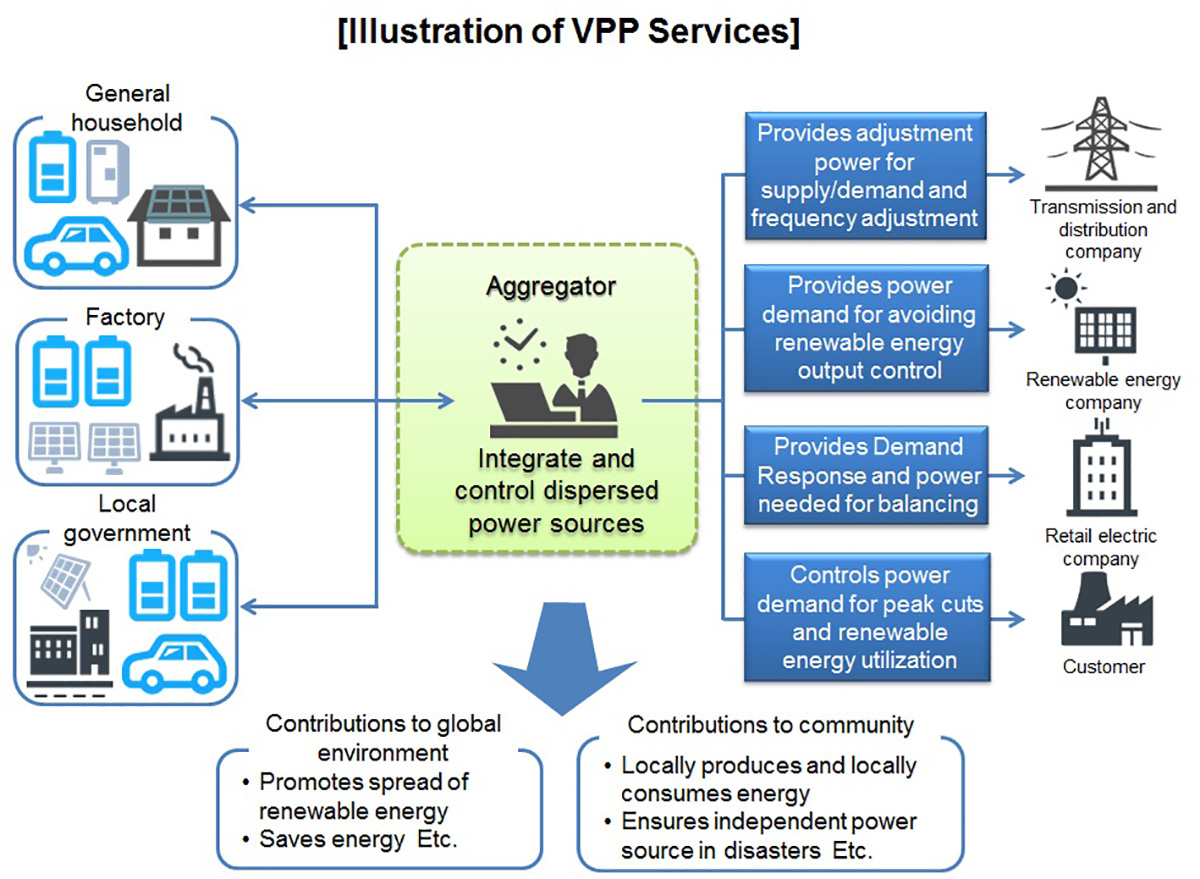

VPP Demonstration Project for Reuse Technology of EV Drive Batteries

The Chugoku Electric Power Company, Incorporated

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)