Reduction of CO2 emissions from automobiles

Shin-Etsu Chemical Co., Ltd.

Outline

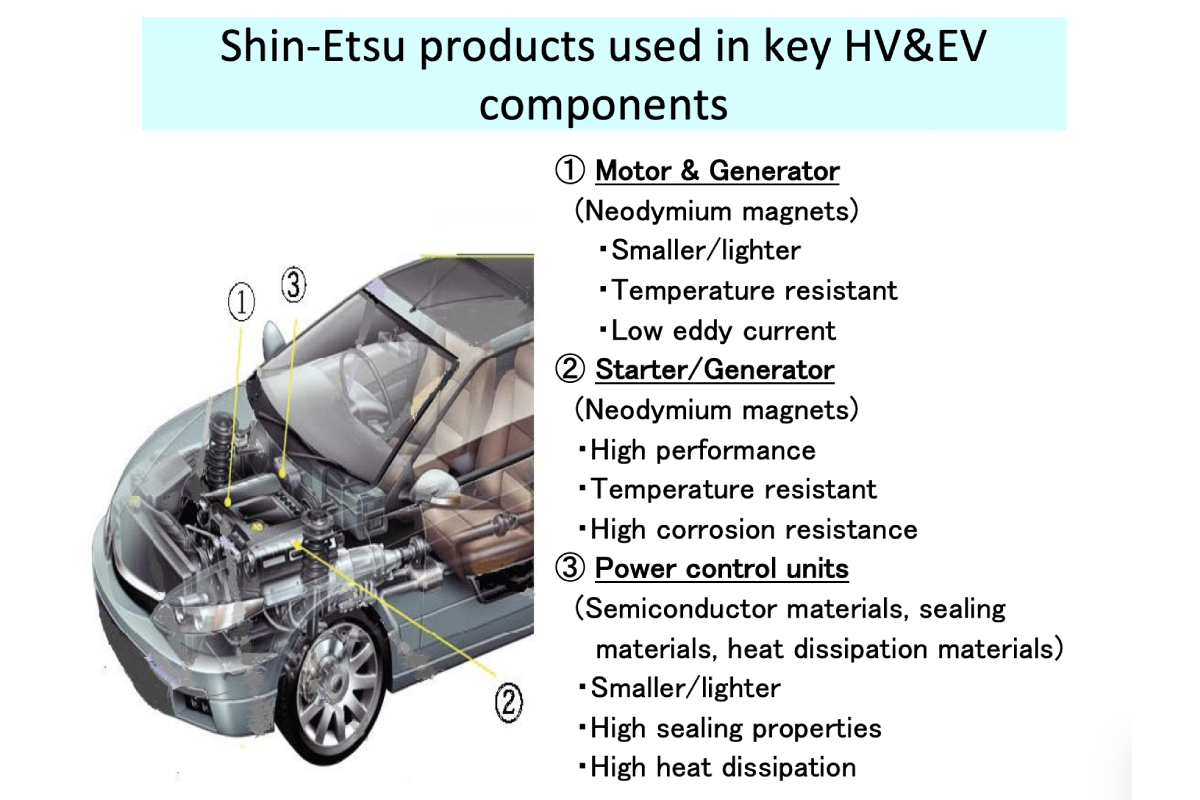

Our neodymium magnets are used in drive motors and generators, which are the most important components of energy-saving vehicles such as HV (hybrid vehicles) and EV (electric vehicles). Our semiconductor materials, sealing materials, and heat dissipation materials are also used in power control units for system control. Energy-saving vehicles can significantly reduce the quantity of CO2 in exhaust gases compared to conventional gasoline vehicles. Carbon dioxide emissions have been reduced by approximately 40% for HV vehicles and 100% for EV vehicles. (Source: Keidanren, Contributing to Avoided Emissions through the Global Value Chain; hereinafter referred to as Keidanren Material)

Our neodymium magnet production base is in Fukui and Vietnam, and the placement of the main factory takes the environment into consideration. Hokuriku Electric Power: 25% of renewable energy ratios, electricity of Vietnam: 38%, which is significantly higher than the national average. We are developing a number of products that can meet the requirements of HV and EV vehicles, which are an aggregate of advanced technologies, such as high-quality magnets, semiconductor materials, sealing materials, and heat dissipation materials, and are increasing the shipping volume year by year. We intend to make significant contributions to CO2 reductions in light of the increasingly accelerated adoption of worldwide energy-saving vehicles.

Description

The fuel efficiency of conventional gasoline vehicles is defined as 7.5 liters/100 km, and the fuel efficiency of energy-saving vehicles is defined as half (50%). (Source: Keidanren Material) Also, the current CO2 reductions are calculated from our current shipments of neodymium magnets for energy-saving motors and generators, assuming that the average annual travel distance of a typical automobile is 10,000 km and the average amount of neodymium magnets used per energy-saving vehicle is 1 kg (based on information from users).

The number of energy-saving vehicles manufactured using our magnets is estimated to be approximately 1.2 million units based on shipments in 2019. The annual gasoline consumption for all conventional gasoline vehicles is:

1.2 million units/year × 10,000 km × 7.5/100 = 900,000 kl/year.

CO2 emissions calculated based on a CO2 emission factor of 0.624 tons per kiloliter of gasoline (Source: Emission factor in the Keidanren Low Carbon Society Action Plan) are: 900,000 × 0.624 = 561,600 tons/year.

As mentioned above, the fuel efficiency of energy-saving vehicles is half that of conventional gasoline vehicles (50%). Therefore, the volume of CO2 reduced by our neodymium magnets and other products is:

561,600 × 0.5 = 280,800 tons/year.

Furthermore, assuming that the life of the vehicle is 10 years on average, energy-saving vehicles using our magnets and other products shipped last year will contribute to CO2 reductions of about 3 million tons over a 10-year period.

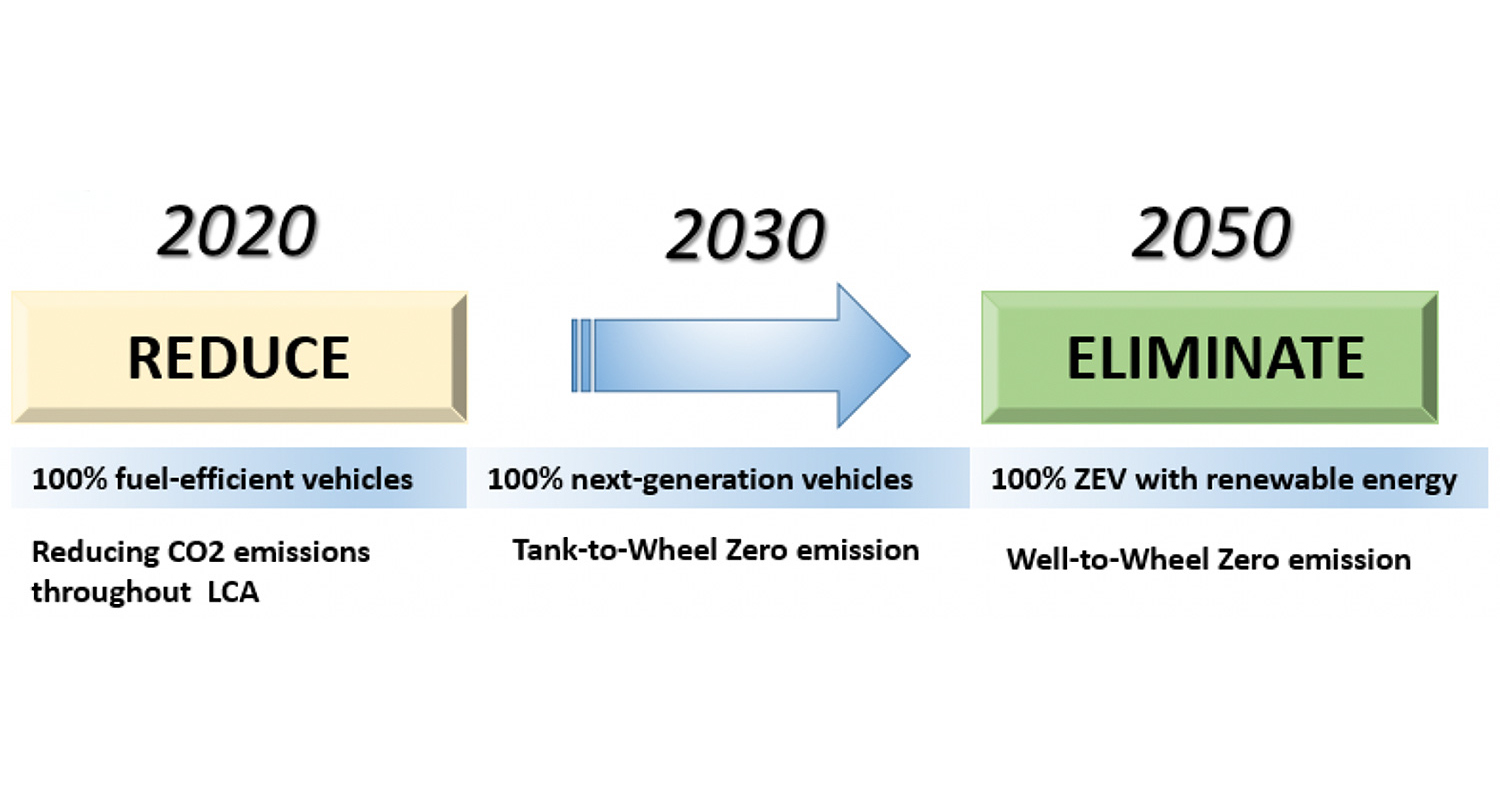

The percentage of energy-saving vehicles is expected to increase rapidly in the future, and the goal is to reach 50% to 70% by 2030 from the current 40%. (Source: Japan Economic Revitalization Headquarters, Growth Strategy 2017) In 2050, energy-saving vehicles will become more popular, and CO2 emissions in automobiles can be expected to be significantly reduced compared to 2019.

Future issues and challenges

〇Responding to increased demand and higher performance due to the spread of energy-saving vehicles

・ Neodymium magnets: Stable supply by expanding production facilities, Establishment of recycling technology, Performance enhancement, miniaturization and weight reduction of magnets

・ Semiconductor materials: Corresponding to miniaturization

・ Encapsulation materials: Realization of high encapsulating and high electric insulation

・ Heat dissipation materials: Realization of high heat dissipation

Partner(s)

Each automobile manufacturer

Supplementary information

Keidanren, Contributing to Avoided Emissions through the Global Value Chain

Keidanren, Low Carbon Society Action Plan

Japan Economic Revitalization Headquarters, Growth Strategy 2017

Other Innovation Challenges

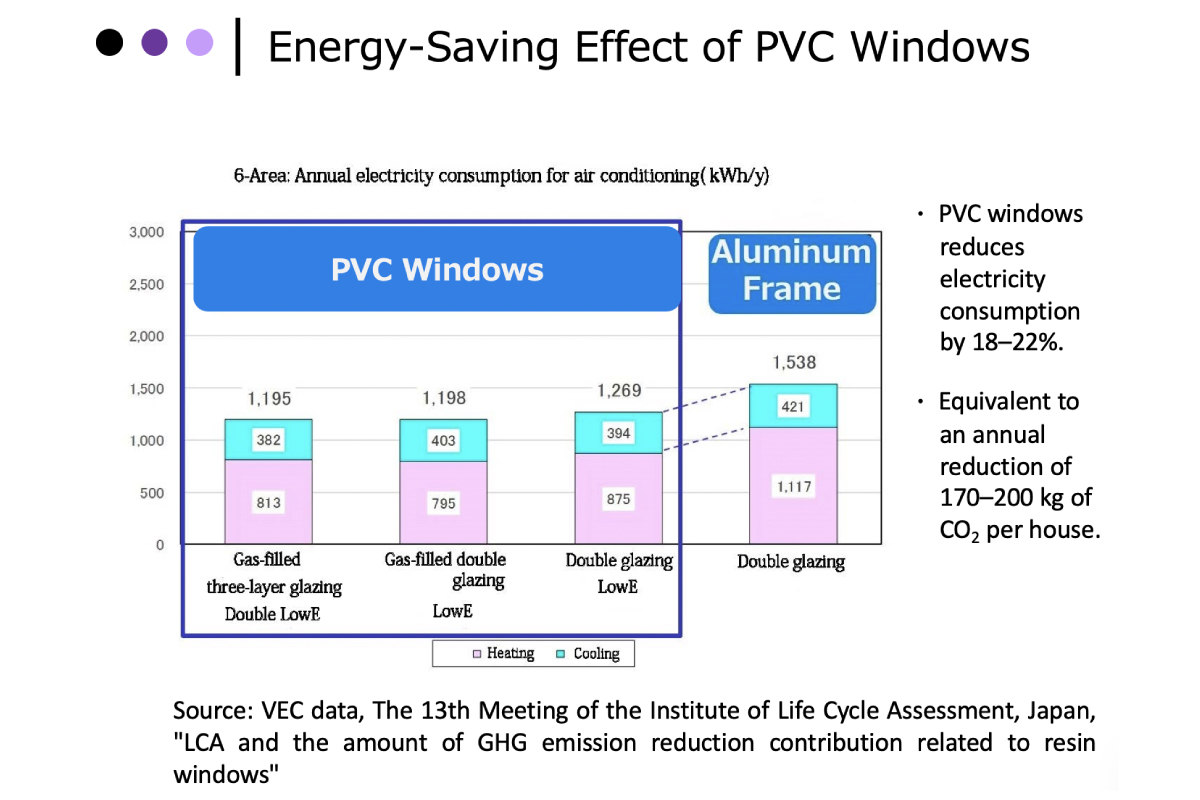

Energy saving and reduction of CO2 emissions by PVC windows

Shin-Etsu Chemical Co., Ltd.

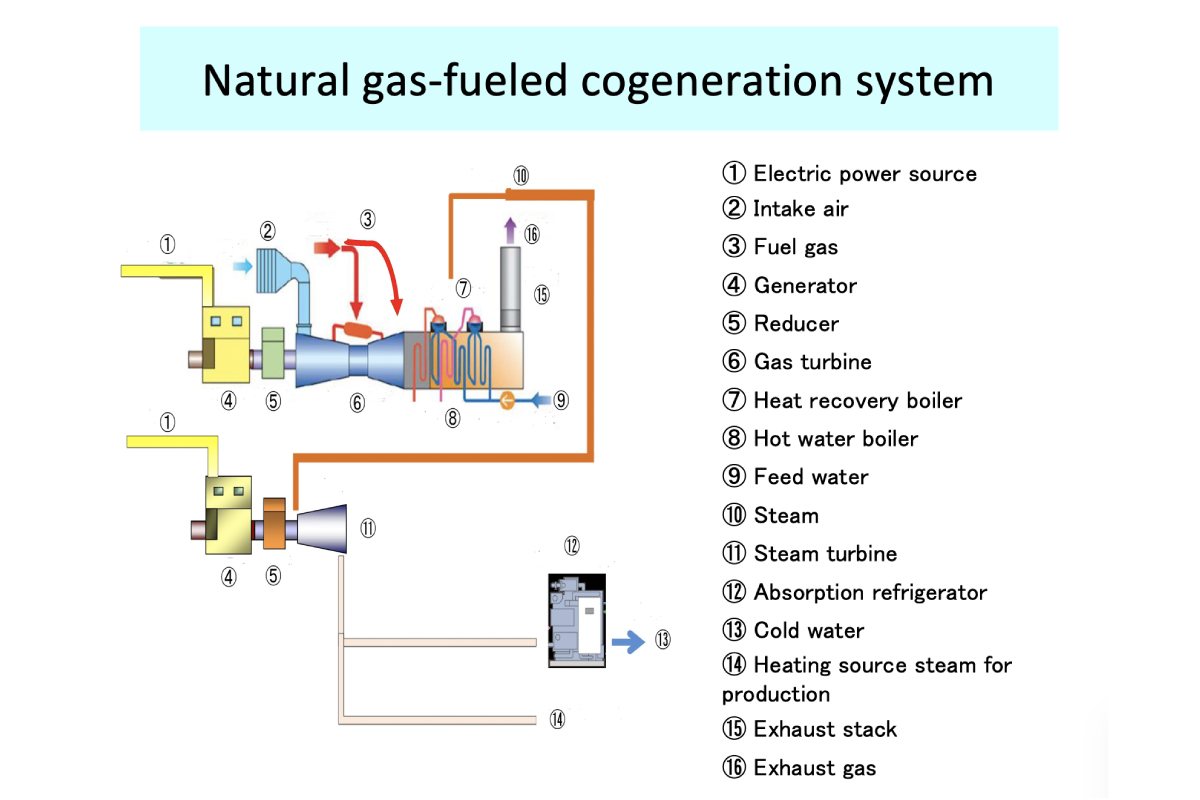

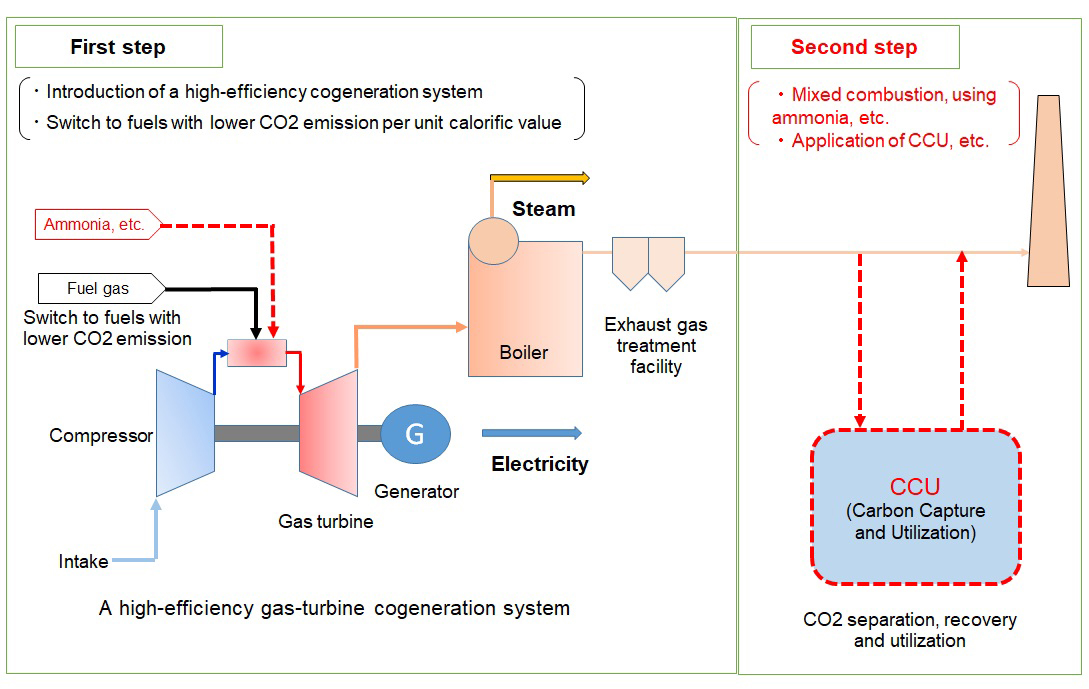

Reduction of CO2 gas by highly efficient gas cogeneration

Shin-Etsu Chemical Co., Ltd.

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.