Installation of “Seawing”, an automated kite system utilizing natural energy

Kawasaki Kisen Kaisha, Ltd.

Outline

We have decided to install the automated kite system “Seawing” * 1 to a large bulk carrier

owned by our company. “Seawing” is mounted on the bow of the vessel and assists propulsion power of the vessel with utilize wind force effectively, which was developed by AIRSEAS * 2

spin off from AIRBUS SE, the major aircraft manufacturer.

“K”Line and AIRSEAS have agreed cooperate on further improvement of the “Seawing” by utilizing the operation and performance data obtained from the ship operation and performance

management system "Kawasaki Integrated Maritime Solutions"(K-IMS)*3 installed in our fleet vessels.

Description

“Seawing combines aeronautical know-how with maritime technology to create a breakthrough in assists propulsion power utilizing wind force, natural energy. A simple switch launches or unfolds, operates and refolds autonomously the kite from the bridge.

The system collects and analyzes weather and marine data in real time, and utilizes that information to optimize performance and ensure maximum safety. Seawing is unfolded by simple operation from the bridge under certain conditions of wind power and wind direction, and assists propulsion power of the vessel with utilize wind force effectively.

In the installation of this system, we carry out intense assessment "Seawing" performance and innovative technology for two years under the close cooperation of AIRSEAS, and confirm that this system can greatly contribute to the reduction of the environmental load associated with the ship's operation. In a case, the bulk carrier can reduce emissions by more than 20%, about 5,200 tons of CO2 annually.

In addition, we and AIRSEAS cooperate on further improvement of their solution by utilizing the operation and performance data obtained from the ship operation and performance management system "Kawasaki Integrated Maritime Solutions"*3 installed in our fleet vessels.

*1 Seawing

Seawing combines aeronautical know-how with maritime technology to create a breakthrough in the maritime transportation sector. A simple switch launches or recovers the kite which unfolds, operates and refolds autonomously. The system collects and analyses meteorological and oceanic data in real-time. Seawing adapts to this information in order to optimize its performance as well as to ensure maximum safety.

*2 AIRSEAS

AIRSEAS as a spin-off of AIRBUS combines aeronautical know-how in modelling and control laws with maritime technology to bring a game changing energy efficiency solution to shipping.

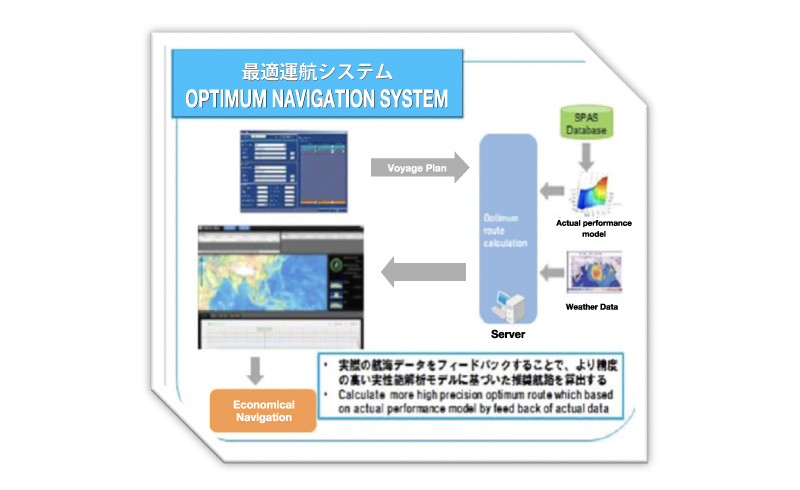

*3 K-IMS(Kawasaki – Integrated Maritime Solutions)

As part of making our principle firm, “K” Line and Kawasaki Heavy Industries, Ltd Group have developed “K-IMS” ; Integrated vessel operation and performance management system, which enables us to utilize the real-time operation data from vessels, so-called Big data, and also enables us to support vessel operation and manage vessel performance in an easy way by grasp of real-time vessel operating conditions, optimum safety route selection, the latest vessel performance and so on through the new data browsing system we have developed. Not only it has contributed to the safe operation and improvement in fuel efficiency of the ship, it also resulted in a dramatic improvement in operational management and ship management efficiency from offices on land.

Moreover, we applied for the “Project to support R&D of advanced technology for safe vessels” that Ministry of Land, Infrastructure and Transport invited the other day with Kawasaki Heavy Industries, Ltd and “K” Line Ship Management Co., Ltd. in our group and our development project “Enhancing analysis accuracy by automatic correction function with hull property model and applying it to safety operation” was adopted because it deserves to the development promotion of “advanced safe vessels” by IoT (Internet of Things) of vessels’ equipment with marine broadband and making use of Big data.

By the success of this project, the accuracy of the Optimum Navigation System in the “K-IMS” is much improved and further improvement of ship safety and economic operations by achievement of appropriate navigation route selection is expected.

K-IMS has been in full operation since March 2016, and further development of the system (Phase-2) was also implemented with the aim of continuously strengthening safety and economic operations even after the start of operation.

In addition to make further effective use of this system, including new features, such as deepening visualization of data obtained through additional development and evaluation of hull aging, etc. we will continue to focus on the development of engine plant operation support and failure prediction diagnostic functions currently under way. We will promote safer and more efficient operations than ever before.

Partner(s)

・ Joint research and development with AIRSEAS (“Seawing”)

・ Kawasaki Heavy Industries Group (K-IMS)

Supplementary information

Other Innovation Challenges

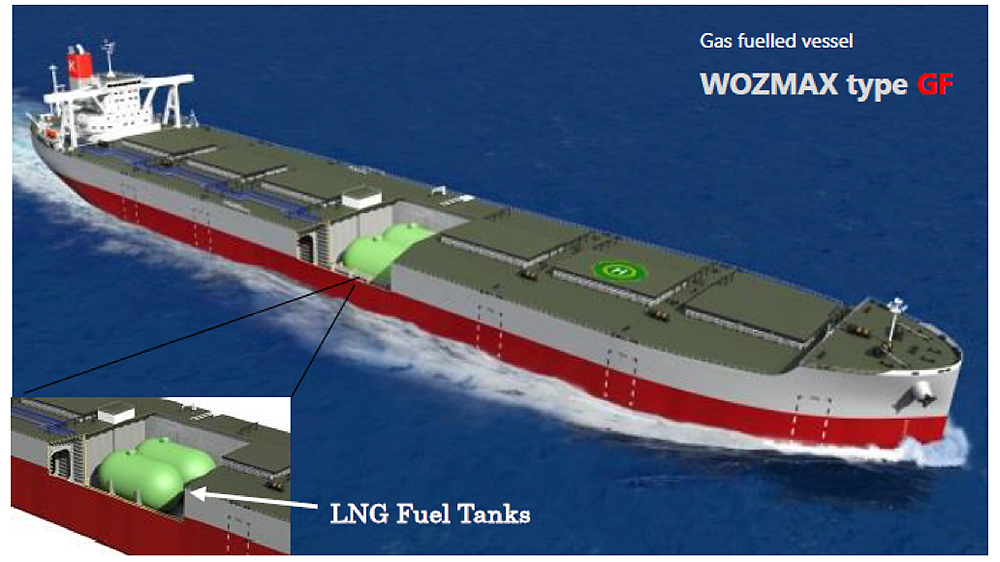

Construction of next-generation eco-friendly car carrier fueled by LNG and start of domestic LNG fuel supply business

Kawasaki Kisen Kaisha, Ltd.

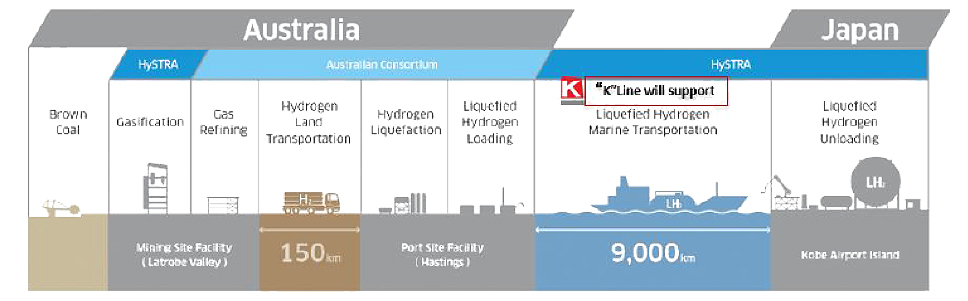

Participated in demonstration test of liquefied hydrogen transport as a general member of HySTRA

Kawasaki Kisen Kaisha, Ltd.

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION