Realization of "green refrigerant" for various applications

AGC Inc.

Outline

Refrigerant (gas) used to cool air is one of the key factors in the performance of air conditioners and freezers. It must have not only excellent thermophysical properties leading to energy saving, but also various properties such as low toxicity and nonflammability, which do not destroy the ozone layer, assuming a leak. Conventionally, as CFCs and HCFCs alternatives, HFCs have been used as refrigerants, but there is a problem that its impact of global warming is extremely high. Therefore, it was agreed internationally to gradually reduce the amount of HFCs used and switch to a “green refrigerant” that has significantly reduced impact on global warming.

In response to this new issue, AGC Inc. has succeeded in developing three types of green refrigerants (compositions and proprietary manufacturing methods) according to applications, utilizing the molecular design and organic synthesis technologies cultivated in its chemicals business. Under the next-generation refrigerant brand AMOLEA®, though we may face lots of difficulties to realize commercial production and supply of the green refrigerants, we will promote the spread and stable supply of these green refrigerants, contributing to the reduction of greenhouse gases in the world.

Description

Refrigerant (gas) used to cool air is one of the key factors in the performance of air conditioners and freezers. It must have not only excellent thermophysical properties leading to energy saving, but also various properties such as low toxicity and nonflammability, which do not destroy the ozone layer, assuming a leak. Conventionally, as CFCs and HCFCs alternatives, HFCs have been used as refrigerants, but there is a problem that its impact of global warming is extremely high. Therefore, it was agreed internationally to gradually reduce the amount of HFCs used and switch to “green refrigerants”, such as Hydro Fluoro Olefines (HFO), or natural refrigerants like CO2, that has significantly reduced impact on global warming. Similar changes are also required for blowing agents used in the production of thermal insulation foams, and cleaning solvents for semiconductors manufacturing process and for precision equipment parts.

“Green refrigerants” (refrigerants, blowing agents, cleaning solvents, etc.) are required to have these various properties, this is why the different chemical substances tend to be used depending on each application. For example, there is a trade-off between flammability and reducing the impact on global warming. It is extremely difficult to discover the optimal balanced substances, furthermore, to develop a process enables stable mass production for such substances at the lowest possible cost.

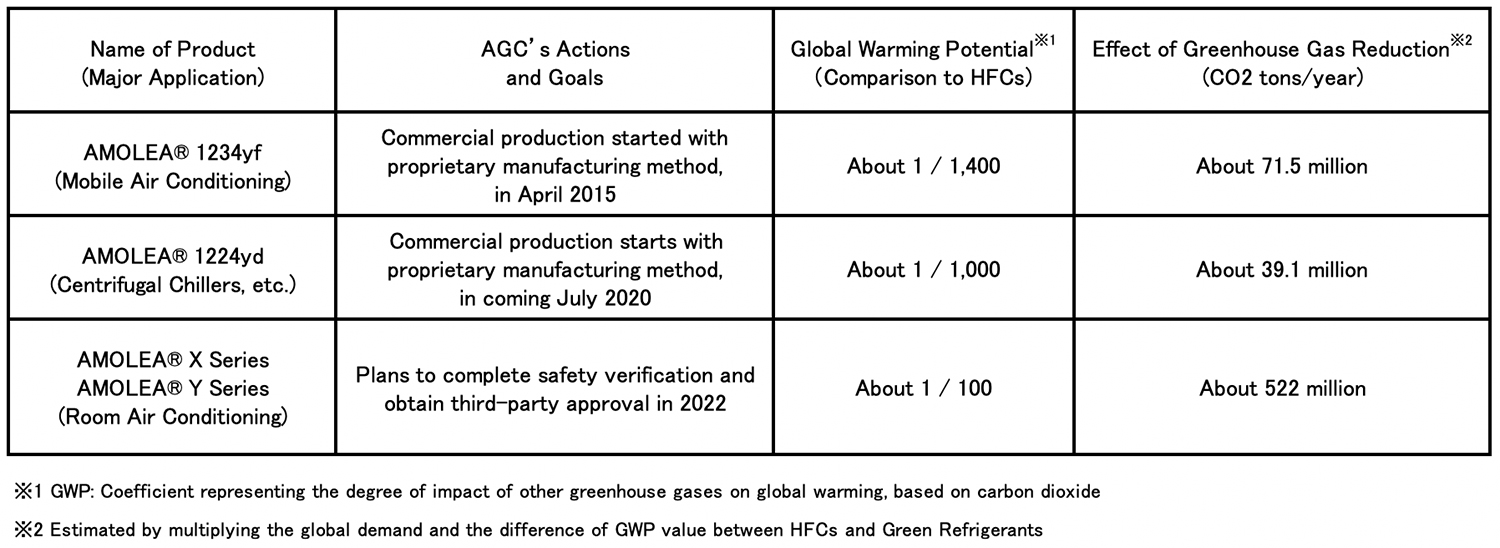

Under the next-generation refrigerant brand AMOLEA®, AGC Inc. has succeeded in developing three types of green refrigerants (two (2) unique compounds, three (3) proprietary manufacturing methods) according to applications, utilizing the molecular design and organic synthesis technologies cultivated in its chemicals business. The developed HFO products are AMOLEA® 1234yf, AMOLEA® X and Y series, which are mainly used as refrigerants, and AMOLEA® 1224yd, which are mainly used as refrigerants and blowing agent, respectively. The potential for global warming (GWP) has been greatly reduced, while maintaining their performance and important properties, such as non-flammable or mildly flammable, and low toxicity. Furthermore, the commercialization and stable supply of two new HFO products has been realized in 2015 through 2019, by developing proprietary reaction process, highly efficient reaction catalyst, and maximizing the use of the existing chemical chain (manufacturing process).

Through the progress of switching to these three types of HFO products, AGC Inc. is committed to lead to the sustainable reduction of environmental impact and the suppression of global warming in Japan and other countries around the world.

Partner(s)

AMOLEA® 1224yd and AMOLEA® X and Y series are developed as a subsidy project of the New Energy and Industrial Technology Development Organization (NEDO).

Related links (in Japanese language only): https://www.nedo.go.jp/activities/ZZJP_100114.html

Supplementary information

Related brochures issued by NEDO

Fluorinated Reduction Technologies 2014 - Toward the Prevention of Global Warming –

https://www.nedo.go.jp/content/100555304.pdf

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION