Reduce CO2 emissions globally by developing and disseminating RENKEI control technology

Azbil Corporation

Outline

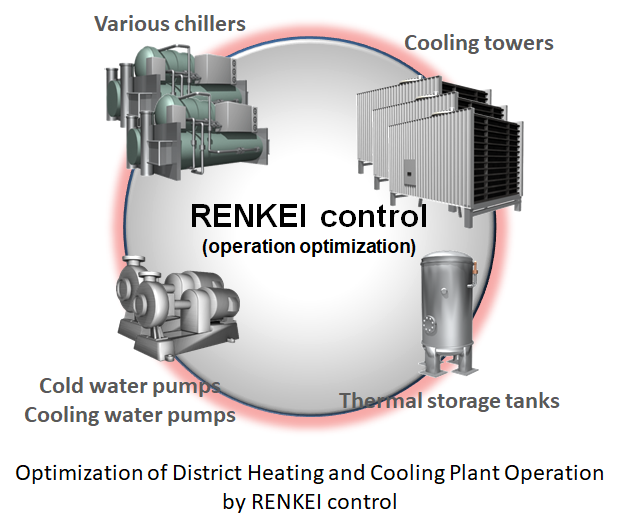

RENKEI control is a control concept that was established by Working Group1 (Energy Management) of the Control and Energy Management Committee of JEITA (the Japan Electronics and Information Technology Industries Association). RENKEI control aims at helping factories and offices to reduce their overall energy consumption.

RENKEI control maximizes overall energy efficiency by coordinating the operation of individual devices, thus reducing overall energy use.

Azbil has been working for some time on the optimization and advanced control of process plants and district heating and cooling systems. Based on that experience, we demonstrated the effectiveness of RENKEI control in a project for the Japanese government’s Joint Crediting Mechanism (JCM; see the METI URL for additional information).

Going forward, Azbil intends to expand the range of applicable applications of RENKEI control by further developing and implementing the technology of cooperative control. In so doing, we will help to improve productivity and reduce CO2 emissions by saving energy at the installation destinations.

Description

Since RENKEI control is the optimization of equipment operation, it does not require upgrading of the existing equipment. Therefore, the energy-saving approach using RENKEI control has the triple advantage of 1) a shorter project period, 2) less required investment, and 3) greater cost-effectiveness than an energy-saving approach that replaces equipment.

RENKEI control is not limited to a specific control algorithm or the like, but some optimization engine is essential.

As this optimization engine, Azbil uses its multivariable model predictive control package, which has many accomplishments in the area of advanced (optimization) control of process plants.

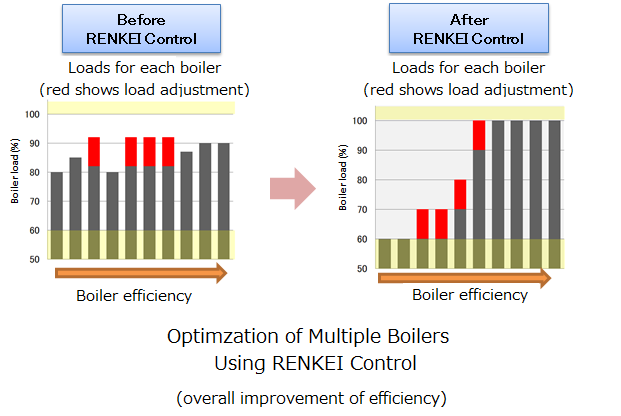

Commonly, the equipment and facilities of factories and buildings are designed to meet maximum demand. Therefore, when operated at intermediate demand, adjustments are required. If there are multiple pieces of equipment supplying energy, there is an opportunity to increase the efficiency of energy use by allocating the load based on the differing energy-efficiency levels of the equipment. Also, on the energy demand side, if multiple pieces of equipment are configured in parallel, there is similarly room for improving the overall energy efficiency.

For this reason, in factories and buildings that operate with a combination of various pieces of equipment, even if individual pieces of equipment with excellent energy-saving performance are installed, there can be a supply-demand mismatch and resulting energy waste, so that the expected energy reduction effect may not be achieved.

RENKEI control optimizes the entire system by making its parts cooperate with each other, thereby reducing supply-demand mismatch and waste and achieving overall energy reduction. This method is cost-effective, and it also has the advantage of providing benefits even in a market downturn (because RENKEI control’s effectiveness is greater when there is a surplus of equipment capacity).

In addition, if some equipment or devices are added or modified after installation, only those parts of the system need to be modified. There is no need to redesign the entire system. This is important for maintaining the effectiveness over a long period of time.

Azbil has already applied RENKEI control to plants in Japan and overseas and has achieved great results, so the concept’s effectiveness has been proven.

Until now, RENKEI control was mainly introduced in environments where there was a DCS (distributed control system) in place, such as process plants or district heating and cooling systems. However, we expect the field of application to expand with the development of IoT and cloud environments.

In order to apply this concept to various new fields in the future, and to contribute to further reduction of CO2 emissions, we are continuing to develop the technology.

Supplementary information

Other Innovation Challenges

Azbil’s virtual power plant (VPP) business integrates and controls various energy resources using the automatic DR system

Azbil Corporation

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION