CO₂ Emission Reduction by C1 Chemical Technology Which Carbon is Stored in Chemical Product

HighChem Company Limited

Outline

HighChem C1 Chemical business is based on large scale SEG® technology licensing in China. With such technology, HighChem makes it possible to produce Ethylene Glycol from non-petroleum sources using synthetic gas as raw material.

As SEG® technology, which has low environmental impact and is high economic efficiency, have been accepted by many Chinese companies. We have been signed a total of 23 licensing agreements of SEG® technology, with a total production capacity of approximately 9.4 million tons per year (as of August 2020).

In addition to energy sources such as coal and natural gas, off-gas from the production of carbide and steel can also be used. Moreover, the process has possibility to use biomass or CO₂ as raw materials so that we have positively tackled with development of these processes.

Description

What is C1 chemistry?

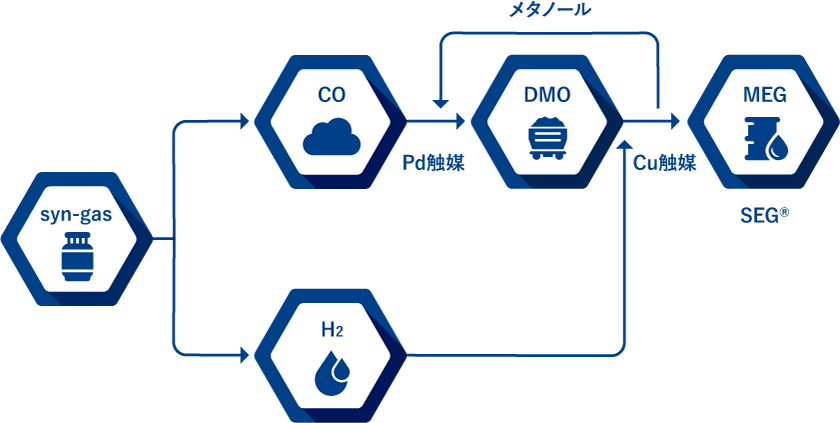

C1 chemistry is an efficiency chemical process for synthesizing chemical products from raw materials such as those that contain one carbon atom (CO, CO₂).

In recent years, the public and private sectors have been working together to recycle carbon by producing chemical raw materials from hydrogen and CO₂, and it is hoped that these efforts will help to reduce CO₂ emissions.

China, a country blessed with abundant coal resources, is developing this technology for coal ahead of Japan. With C1 Chemistry, the carbon atom is stored in the chemical product, significantly improving the efficiency of using the carbon atoms in coal and reducing the amount of CO₂ emission, which leads to more efficient usage.

Our C1 Chemistry Business

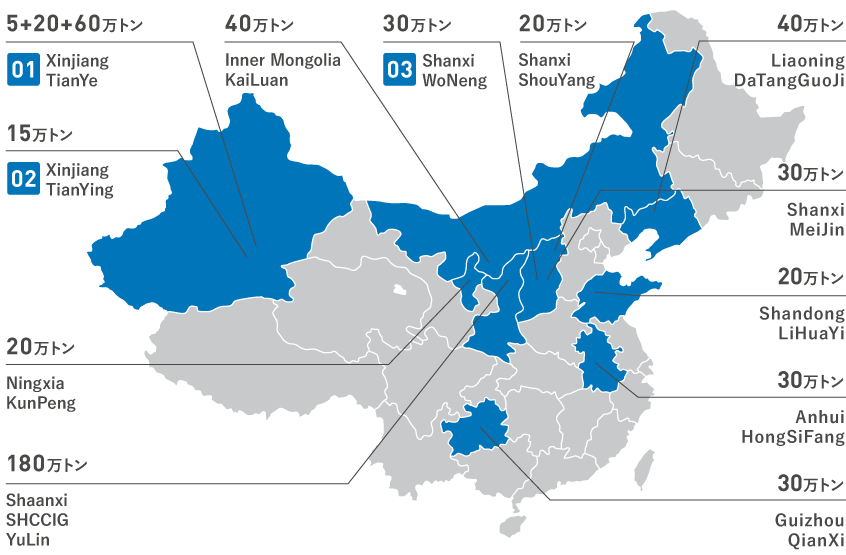

Based on C1 Chemistry business, HighChem is expanding its licensing business and catalyst manufacturing/sales business of SEG® technology on a large scale in China. HighChem, in collaboration with Ube Industries, Ltd., is developing a SEG® technology licensing business for energy-related companies in China. We have signed a total of 23 licensing agreements of SEG® technology, with a total production capacity of approximately 9.4 million tons per year. More than 1 million tons of capacity is under commercial operation (as of August 2020).

SEG® licensing business

Features

・ Low environmental impact and highly economical process

Conventionally, ethylene glycol is produced by the "ethylene method" using petroleum as a raw material, but the carbon atom utilization rate is as low as 70%, with 25% being emitted as the form of CO₂. However, the SEG® method achieves a carbon atom utilization rate of 95%, making it a process with low environmental impact and high economic efficiency. Therefore, half of the ethylene glycol produced in China has been changed to be produced by the SEG® method.

・A Wide Range of Raw Materials

In addition to energy sources such as coal and natural gas, off-gas from the production of carbide and steel can also be used.

In August 2020, the world's first plant to produce ethylene glycol from off-gas at a steel mill went into operation. This project is run by Shanxi Woneng Chemical Technology Co., Ltd., a wholly owned subsidiary of a major Chinese private steel company, with an annual production of 300,000 tons. If the plant operates all year, it is expected to reduce 560,000 tons of CO₂ emission annually.

There are total of 750,000 tons capacity of Ethylene Glycol using off-gas as raw material, and if all of these plants go into operation, it will reduce CO₂ emissions by about 1.25 million tons per year (as of August 2020).

Moreover, the process has possibility to use biomass or CO₂ as raw materials so that we have positively tackled with development of the process.

Partner(s)

Ube Industries, Ltd.

Other Innovation Challenges

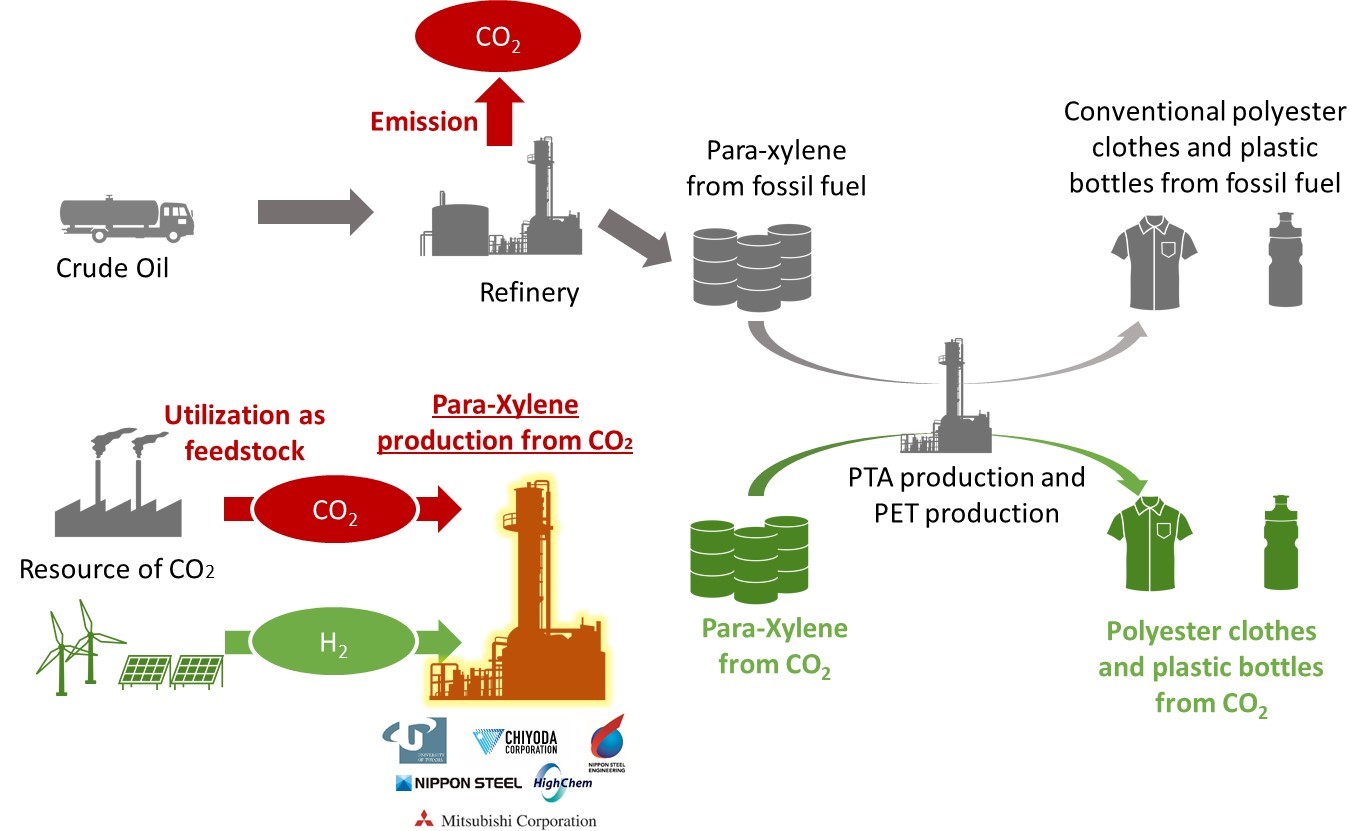

Initiation of “Technology Development for Para-xylene Production from CO₂”

HighChem Company Limited

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION