“Single-use plastics” can be mechanically recycled with a new fiber reinforcing technology for CO₂ emission reduction

Furukawa Electric Co., Ltd.

Outline

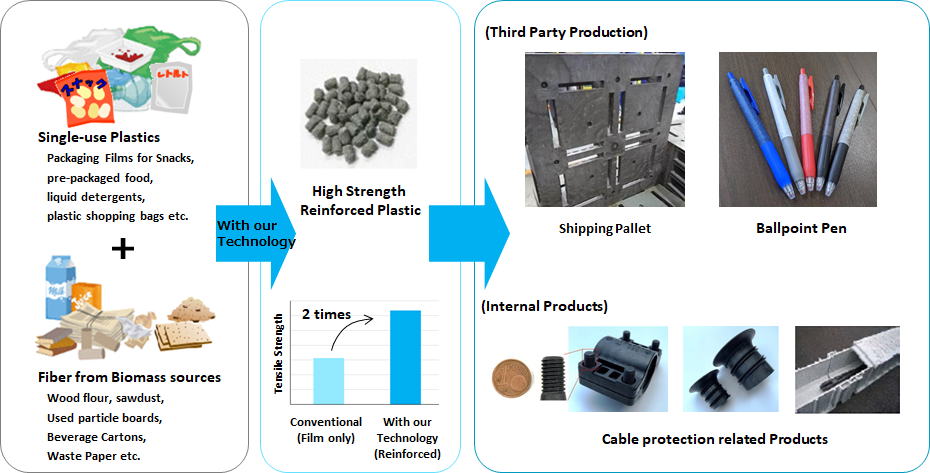

Furukawa Electric has developed a new mechanical recycling technology which allows “Single-use plastics” to be regenerated into high strength reinforced plastics. Currently, the vast majority of the collected “Single-use plastics” waste; Multi-layered film waste in particular, is incinerated. This new technology makes it possible to regenerate such “Single-use plastics” into higher strength reinforced plastics with the utilization of bio-fibers (wood chips, paper etc.). The implementation of this technology will enable more “Single-use plastics” waste to be mechanically recycled, resulting in reduction of CO₂ emissions from incinerating waste. Furukawa Electric has already begun the use of material processed with this technology into its own products, and will aim to communicate this technology to the world and drive its widespread implementation in order to contribute in the reduction of CO₂ emission.

Description

1. Background

“Single-use Plastics” are disposable plastics which are intended to be used once before they are thrown away. These include, among other items, packaging used for food and liquid detergents. At present, even though such plastic packaging waste is collected, instead of being recycled, it usually ends up being incinerated, and therefore becomes a cause of CO₂ emission. In particular, packaging film used for snacks and pre-packaged foods often consists of multi-layers of various types of materials; eg. Polyethylene, Polypropylene, PET, Nylon, Aluminum, paper etc., which are difficult to separate. Due to such complex structures, when mechanically recycled by ordinary methods, the mechanical strength degrades heavily, and can only be used for low-grade products. For this reason, the vast majority of such waste is currently incinerated (including thermal recovery). On the other hand, such film packaging is not only convenient, but also has superb functional properties to protect food and other contents. This allows products to stay longer on the shelves, as well as due to its lightness, makes transportation more efficient, which at the end does contribute in reducing the environmental impact. For this reason, rather than to deplete plastic packaging completely, establishing a sufficient recycling scheme for such plastic packaging is vital to reduce the overall Carbon footprint.

2. Technology developed

The technology which Furukawa Electric has developed, is a new upcycling technology which can increase the strength of even the most difficult to recycle multi-layered packaging by reinforcing the material with fiber. With the implementation of this technology for processing plastic waste, it would contribute in reducing CO₂ emission, by reducing the amount of plastic waste being incinerated. As for the reinforcement fiber source, fiber originating from Carbon Neutral Biomass sources will be used. Source of Fiber could be from Pulp or Cellulose Fiber, but also from Wood Flour, Sawdust, Wood waste (used particle boards etc.) or Paper Waste as well. Currently, some of such waste gets incinerated, and therefore, making the use of these fiber waste would also contribute in the reduction of CO₂ emission.

3. Application

As an example, beverage carton is composed of low density polyethylene, paper and Aluminum. The paper contents are separated at the Paper Mills when used beverage cartons are collected in order to use them for recycled paper. However, the residue after the extraction of paper from the beverage cartons, consisting of low density polyethylene, Aluminum, some paper as well water, is in many cases incinerated. The newly developed technology will be able to upcycle such residue, by increasing the tensile strength up to the level of high density polyethylene, making mechanical recycling more feasible. Furukawa Electric has already begun using this residue as a material source for its own products. In addition, sample production of Ballpoint pens and Shipping Pallets made from Potato Chips and Chocolate packaging waste processed with this technology has been successfully conducted.

4. Future Plans

Furukawa Electric will not only limit the use of this technology internally, but will widespread the implementation worldwide. By doing so, incineration of “Single-use plastics” waste can be reduced, and we truly believe that regenerating more waste into new products, will contribute in reducing CO₂ emission in a larger scale worldwide.

Supplementary information

Other Innovation Challenges

Research of C2 compounds generating technology by the electrolytic reduction of CO₂

Furukawa Electric Co., Ltd.

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION

.png?id=2&tid=707&imageNumber=1)