Promoting Smart Factory Technologies

YASKAWA ELECTRIC CORPORATION

Outline

Promoting Smart Factory Technologies

Over the years, YASKAWA Electric has been creating mechatronics technologies and products such as servos, inverters, and robots in order to provide a wide range of solutions that reduce energy consumption and improve productivity at its customers’ production sites.

In order to contribute to the creation of a low-carbon society in the future, we are going to focus on developing the smart factory technologies described below while promoting the diffusion of related products with the goal of further improving the efficiency and productivity at production sites.

1. Technologies that make motor drives more compact and efficient

2. High-productivity solutions that utilize IoT and AI

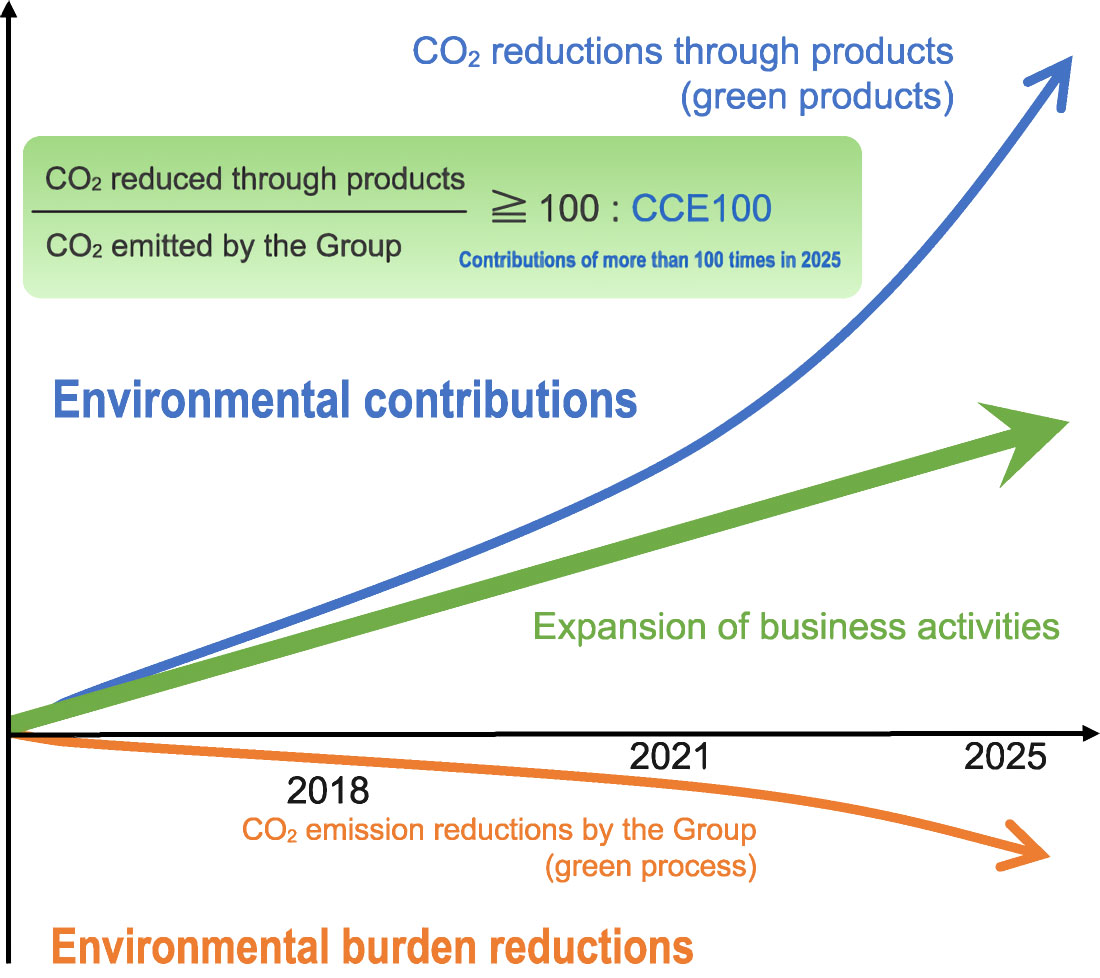

Including these initiatives, YASKAWA Electric aims to contribute to the preservation of the environment through both environment burden reductions (green process) associated with production activities and energy consumption improvements through the proliferation of products (green products). Setting CCE100: Contribution to Cool Earth 100 (to reduce CO2 emissions by our company and reduce emissions by more than 100 times in 2025 through our products) as one of the objectives of these commitments, we will promote environmental contribution activities toward realizing the above.

Description

1. Technologies that make motor drives more compact and efficient

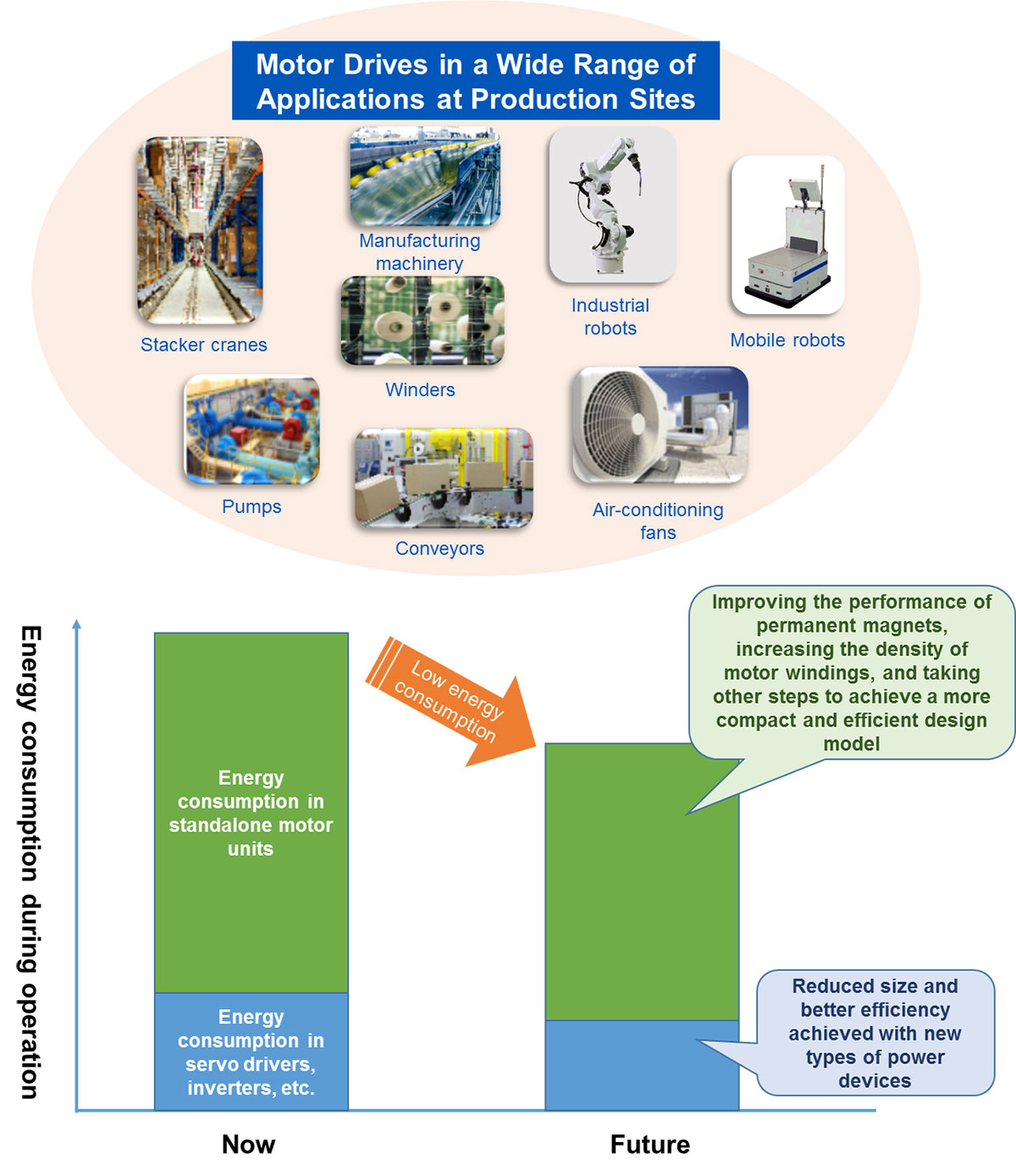

Motors are used in a wide variety of drive systems. They are believed to account for 50% or more of global energy consumption. Robots, production machinery, fans, and other types of manufacturing equipment used at production sites are also powered by motor drives. Thus, maximizing the efficiency of industrial motor drives, including servo and inverter drives used as power sources, is directly linked to reducing energy consumption at production sites. On the other hand, making industrial motor drives more compact reduces the energy required for the motors to run and decreases the weight of moving units (such as mobile robots) that feature industrial robots or motor drives.

Our efforts to make industrial servo drives more compact and efficient can be divided into two large categories: (1) making standalone motor units more compact and efficient and (2) making servo drivers, inverters, and other parts that power the motors more compact and efficient. These efforts aim to reduce energy consumption in motor drives.

(1) Due to the introduction of the Top Runner Program in Japan, manufacturers have an obligation to meet high-efficiency targets. Therefore, in an effort to make our standalone motor units more compact and efficient, we also ensured those criteria were met. In the future, we will strive to improve the performance of permanent magnets, increase the density of motor windings, and take other steps to achieve an even more compact and efficient design model.

(2) To make servo drivers, inverters, and similar parts more compact and efficient, we have given particular attention to innovative technologies that minimize losses in power conversion circuits. We are seeking to reduce the size and improve the efficiency of our products by equipping our power conversion circuits with new types of power devices that use advanced materials such as gallium nitride (GaN) and silicon carbide (SiC). Our goals for the future include utilizing power devices designed with cutting-edge materials in order to be able to offer products that are more compact and efficient.

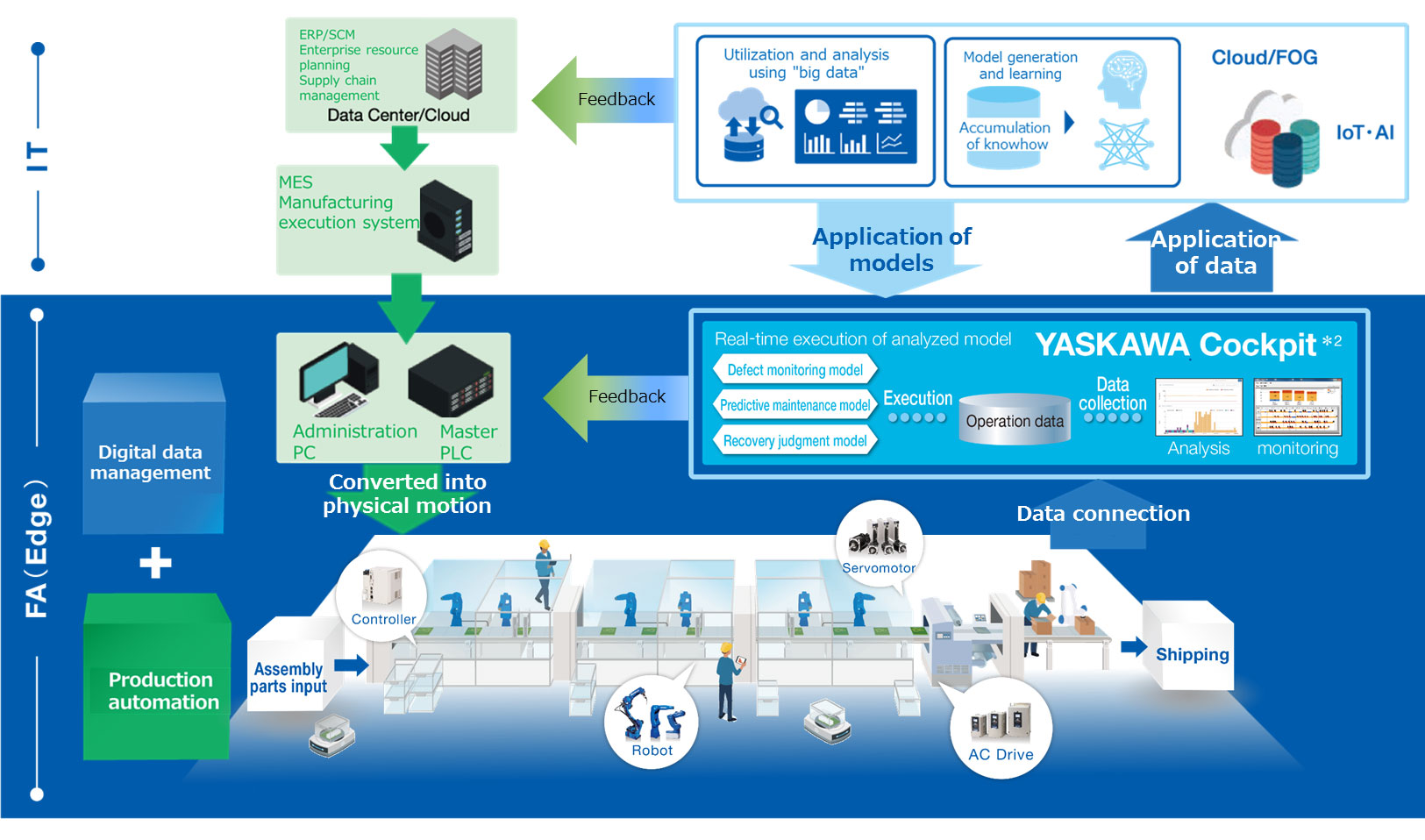

2. High-productivity solutions that utilize IoT and AI

Nowadays, it is becoming more and more important for a production site to be able to manufacture a large variety of products in small quantities and to change production quantities and product types in a flexible manner according to consumers’ needs. This trend is going to grow even stronger in the future.

YASKAWA Electric is committed to creating new solutions that improve productivity by utilizing IoT, AI, big data, and similar tools covered in our own original concept of i3-Mechatronics*. By integrating data utilization with our mechatronics products, we can detect and remedy production site issues. Our aim is to provide high-productivity solutions for shorter lead times, better rolled throughput yield (fewer defective products), higher utilization rate, and other improvements. These solutions are also designed to reduce the amount of energy required for the production of a single unit at a plant.

* i3-Mechatronics: The original concept of mechatronics (created by YASKAWA Electric's engineers in 1969) has been enhanced with three additional notions, namely the "three i's": integrated, intelligent, and innovative. In other words, we have embedded data utilization in our mechatronics products in order to provide solutions for management issues directly from our customers' production sites.

Supplementary information

Information about i3-Mechatronics:

https://www.yaskawa-global.com/product/i3-mechatronics

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION