Power Unit for 2-Motor System “4GL-IPU”

Mitsubishi Electric Corporation

Outline

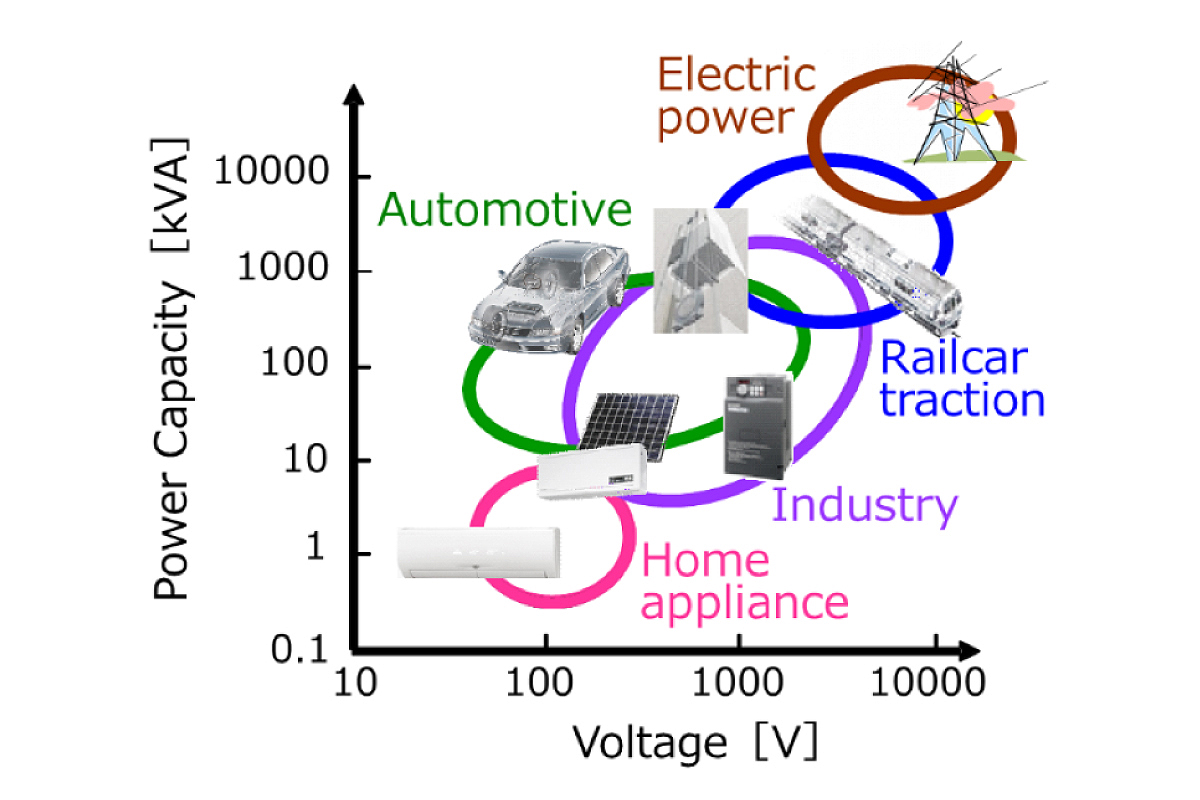

There are various types of electric vehicles, such as HEV: hybrid electric vehicles and BEV: battery-powered electric vehicles, from 1-motor HEVs in which the engine plays a leading role to BEVs in which only the motor drives. The conventional two-motor HEVs use the engine output together, so the motor output was smaller than the engine output. However, recently there has been an increase in the number of new fully electric two-motor HEVs that run only on motors. In this fully electric system, both higher output and downsizing are necessary. To meet this requirement, we have developed the 4GL-IPU with a high heat radiation power module and our company's original step-up circuit as product for fully electric two-motor HEV in our 4th generation IPUs (Integrated intelligent Power drive Unit).

We will challenge further downsizing and higher functions of IPU to keep contributing to popularizations of electric vehicles that realize environmental performance and fun to drive.

Description

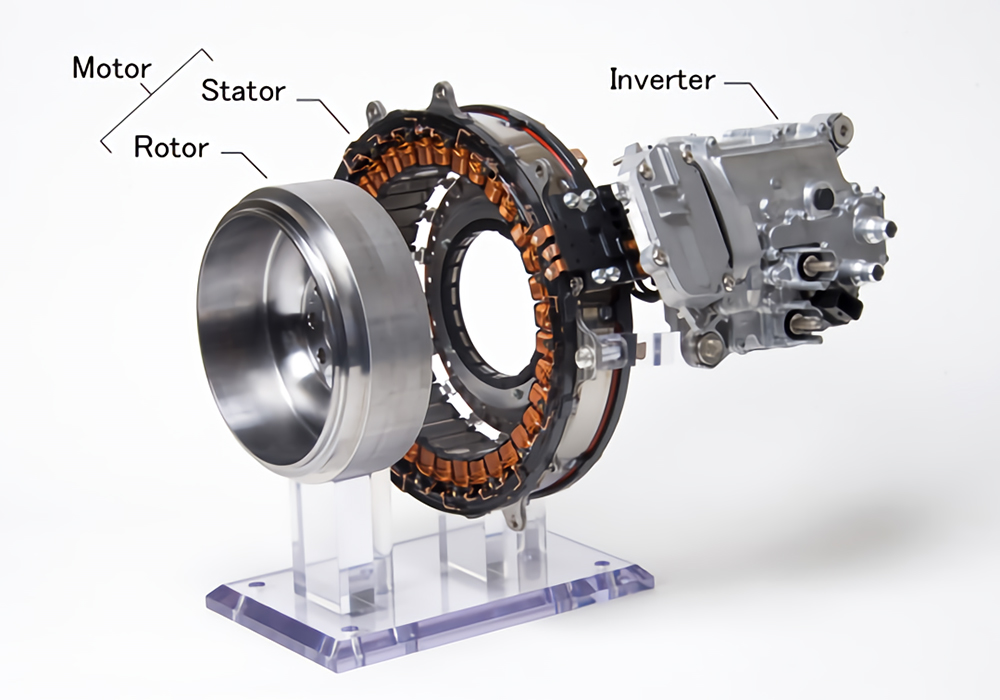

Mitsubishi Electric Corporation first commercialized Intelligent Power Modules (IPM) for hybrid electric vehicles in 1997. Since then, we have been contributing to the electrification of vehicles by releasing products such as 4GS-Integrated intelligent Power Unit (4GS-IPU) with heat sink and motor control functions as a result of our effort to downsize IPM, increase the output power, and integrate the functions. Our newly developed 4GL-IPU described in this article is for the high-power 2-motor systems, which enables motor-driven travel even in a high-speed region and in full acceleration. (Fig. 1)

Characteristics of the 4GL-IPU

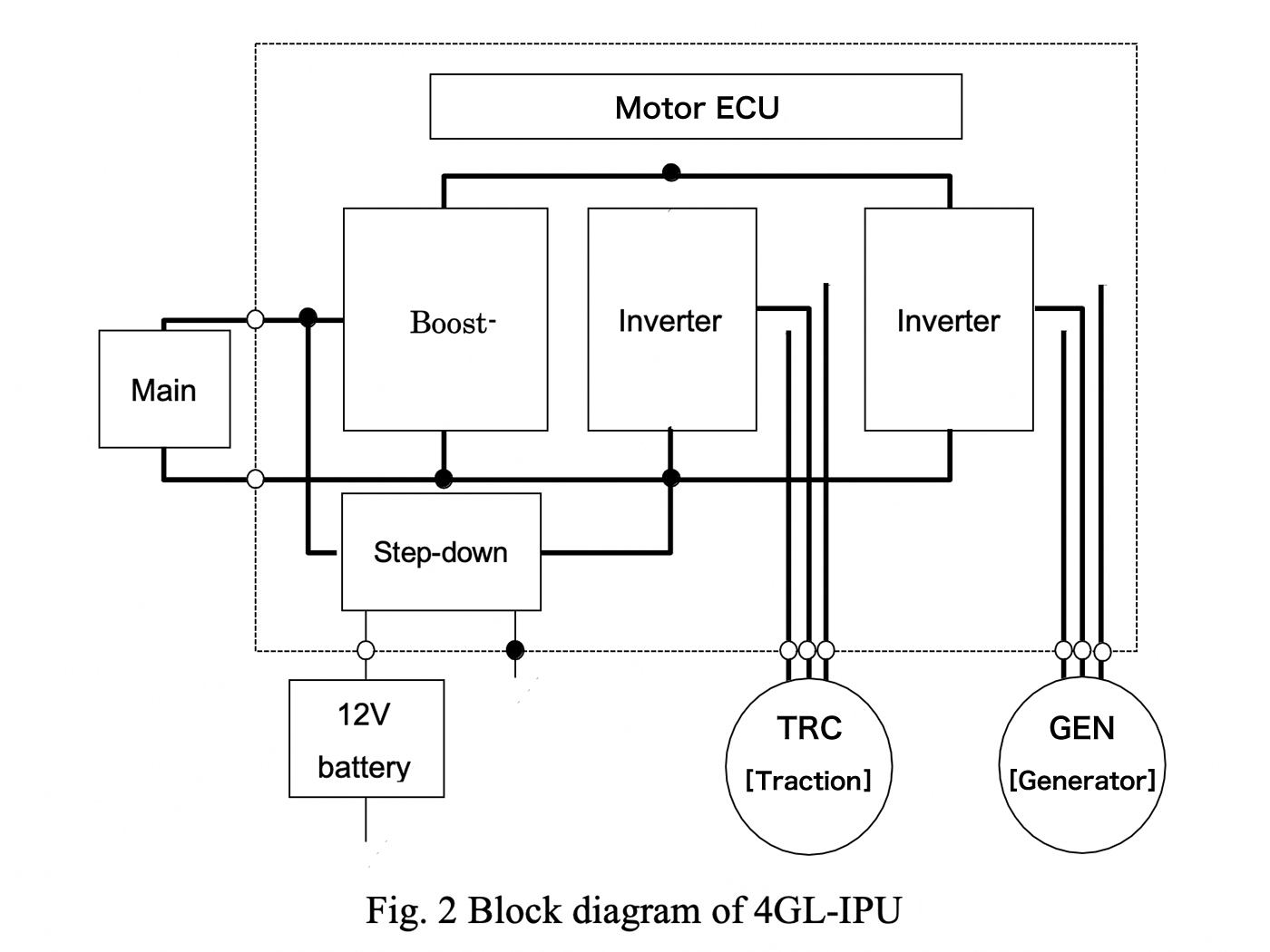

4GL-IPU has two high-power inverters: one for the high-power traction motor and the other for the generator motor that supplies high power to the traction motor. It also has a voltage boost-up converter that boosts the voltage of the main battery and an insulated step-down converter that lowers the voltage of the main battery to 12 V for the auxiliary battery (Fig. 2).

Source: Mitsubishi Electric ADVANCE Magazine

https://www.mitsubishielectric.com/en/about/rd/advance/index.html

Supplementary information

1.Global Official Website: Initiatives that contribute to addressing environmental issues of Mitsubishi Electric Corp. Automotive Equipment Group

https://www.mitsubishielectric.com/en/sustainability/csr/management/social_contributions/automotive/index.html

Other Innovation Challenges

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

Crankshaft ISG System for 48V Hybrid Vehicles

Mitsubishi Electric Corporation

D-SMiree System for Medium-and Low-voltage DC Distribution

Mitsubishi Electric Corporation

Energy saving technology for power electronics equipment with SiC devices

Mitsubishi Electric Corporation

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION