Nihonbashi Smart Energy Project

Mitsui Fudosan Co., Ltd.

Outline

The Nihonbashi Smart Energy Project established the Nihonbashi Energy Center within Nihonbashi Muromachi Mitsui Tower, a new building in Nihonbashi Muromachi, Chuo-ku, Tokyo, to supply electricity and heat to the surrounding area. This joint project with Tokyo Gas Co., Ltd. began operation on April 1, 2019.

The project uses a large-scale cogeneration system (CGS) fueled by city gas supplied through a medium-pressure gas pipeline with a track record of high resilience to earthquakes. Together with grid electricity, the project realizes Japanese first multiplex electricity for the area, including existing buildings. By continuously supplying electricity even during a wide-scale power outage, the system increases the energy resilience of the local area to make Nihonbashi robust in disasters and a highly competitive global neighborhood.

The project has also implemented a heat supplying business that utilizes waste heat from the CGS and highly efficient heat sources, reducing CO2 emissions from the supply area by approx. 30% through local production for local consumption of energy and Japan’s first optimal operations control using information networks that connect heat source equipment for the area, including existing buildings.

Description

1. Renewing the entire neighborhood’s energy

Mitsui Fudosan is contributing to a sustainable society through the creation of neighborhoods that solves social issues such as energy and environmental problems, low birthrate and rapid aging and industrial renovation. In Nihonbashi, Mitsui Fudosan has worked on the Nihonbashi Revitalization Plan, based on the concept of “Proceeding to Create While Retaining and Reviving.” Promotion of smart cities in central urban areas such as Nihonbashi, which have a concentration of office buildings and retail facilities, are of urgent priority from the viewpoint of stable economic activity and maintenance of city functions, and Mitsui Fudosan believes it is necessary to enhance energy resilience throughout the whole area to achieve that.

The Fundamental Plan for National Resilience calls for energy resilience, and Tokyo Gas has prepared medium-pressure gas pipelines, which provided stable energy supply following both the Hanshin-Awaji and Great East Japan Earthquakes, as part of its efforts to strengthen its disaster readiness and introduced an independent distributed power supply in the form of a CGS. Tokyo Gas has been involved in initiatives regarding the effective use of energy in electricity and heat as a local energy supplier for approx. half a century and aims to realize cities with enhanced energy resilience that are in harmony with the environment.

Mitsui Fudosan and Tokyo Gas are aware that enhancement of overall energy resilience and environmentally friendly neighborhoods are significant issues for Japanese cities, and this initiative, the first of its kind in Japan, will leverage their strengths and knowledge in renewing the entire neighborhood’s energy, including existing buildings.

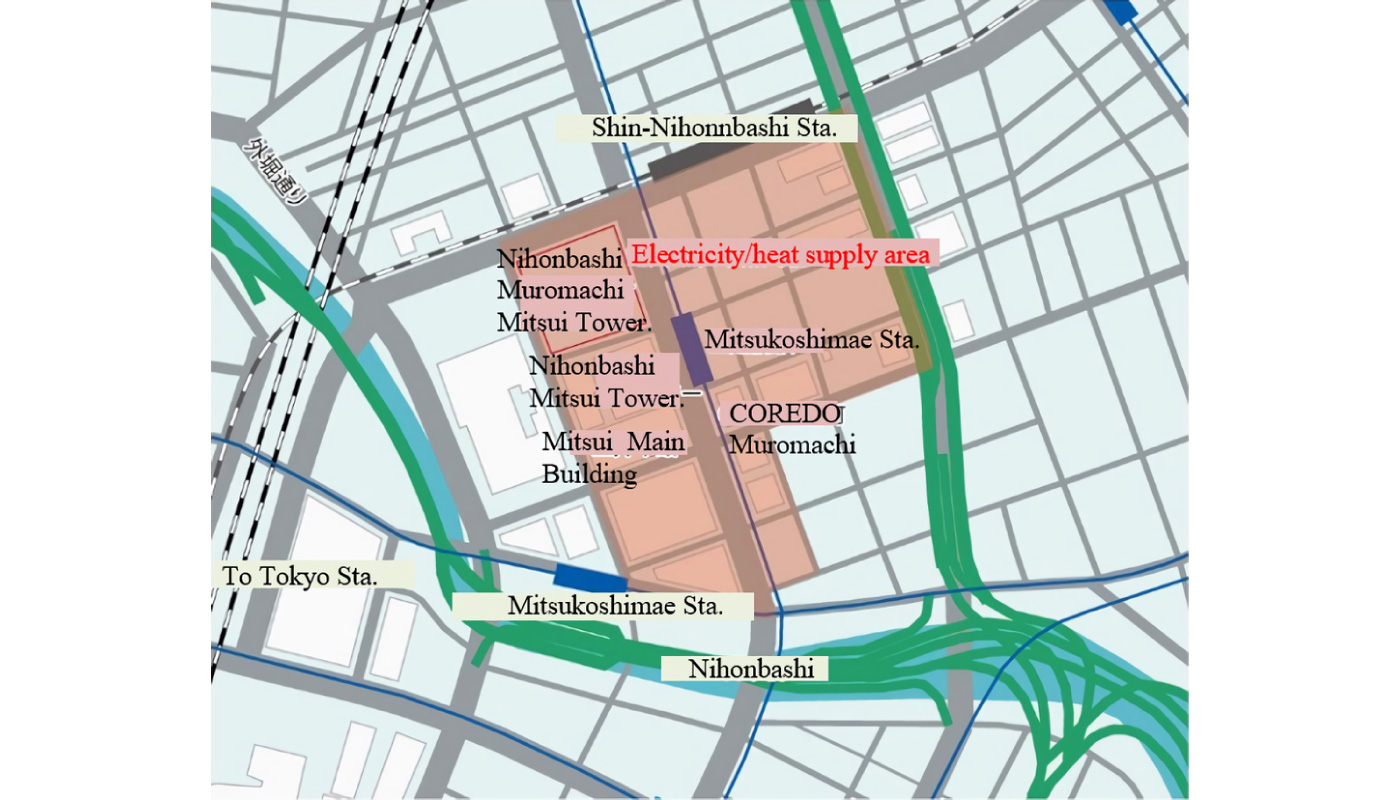

Fig. 1. Supply area

2. Raising energy resilience throughout the entire neighborhood, including important cultural properties

Mitsui Fudosan and Tokyo Gas have built Japan’s first energy network by installing a large-scale CGS in Nihonbashi Muromachi Mitsui Tower and at the same time laying out an independent power line to supply surrounding buildings and retail facilities with energy on a regular basis and during emergencies.

The large-scale CGS installed uses highly reliable medium-pressure gas pipelines to generate electricity following a disaster, providing the power supply required (corresponding to 50% of peak level) for the entire neighborhood’s business continuity plans (BCP) at a time of widespread power outage. The range of power supply will extend to a total area of approx. 10.8 million ft2 (approx. 1,000,000 m2) encompassing approx. 20 buildings including important cultural properties such as the Mitsui Main Building and Nihombashi Mitsukoshi Main Store, as well as other existing buildings, such as the head office of Takeda Pharmaceutical Company Limited. Energy can also be supplied to facilities to temporarily accommodate those unable to return to their homes following a disaster, which contributes to safe and secure neighborhoods with enhanced energy resilience in the entire area.

Welded steel pipes have been used for the piped medium-pressure gas pipelines as they have the excellent strength and flexibility needed to withstand a large-scale land transformation, and gas supply basically does not end. The pipes are known to have had high seismic resistance during the Hanshin-Awaji and Great East Japan Earthquakes and enable stable energy supply during emergencies. Moreover, the medium-pressure gas pipelines are looped to ensure multiple supply routes and secure supply stability.

<Supply Capacity>

Electricity: Approx. 43,000 kW

Cool heat: Approx. 100 GJ/h

Warm heat: Approx. 60 GJ/h

<Facility Overview>

Gas engines: 7,800 kW × 3 units

Waste heat boilers: 4t/h × 3 units

Absorption refrigerating machines with exhaust heat recovery: 1,400 RT × 3 units

Centrifugal chillers: 1,350 RT × 2, 800 RT × 1, 300 RT × 1 units

Steam boilers: 3t/h × 2 (single-fuel fired, gas), 2t/h × 3 units (dual-fuel fired, gas and oil)

3. Environmentally friendly neighborhood creation by realizing energy saving and CO2 reduction

The project realizes energy saving and CO2 reduction in the following three ways.

(1) Establishment of a power generation plant in the area for local production and local consumption of energy

(2) A heat supply business using waste heat generated during power generation

(3) Building the Nihonbashi Energy Management System to utilize information networks to realize Japanese first optimally operated heat source facility for an entire community, including heat source facilities of existing buildings

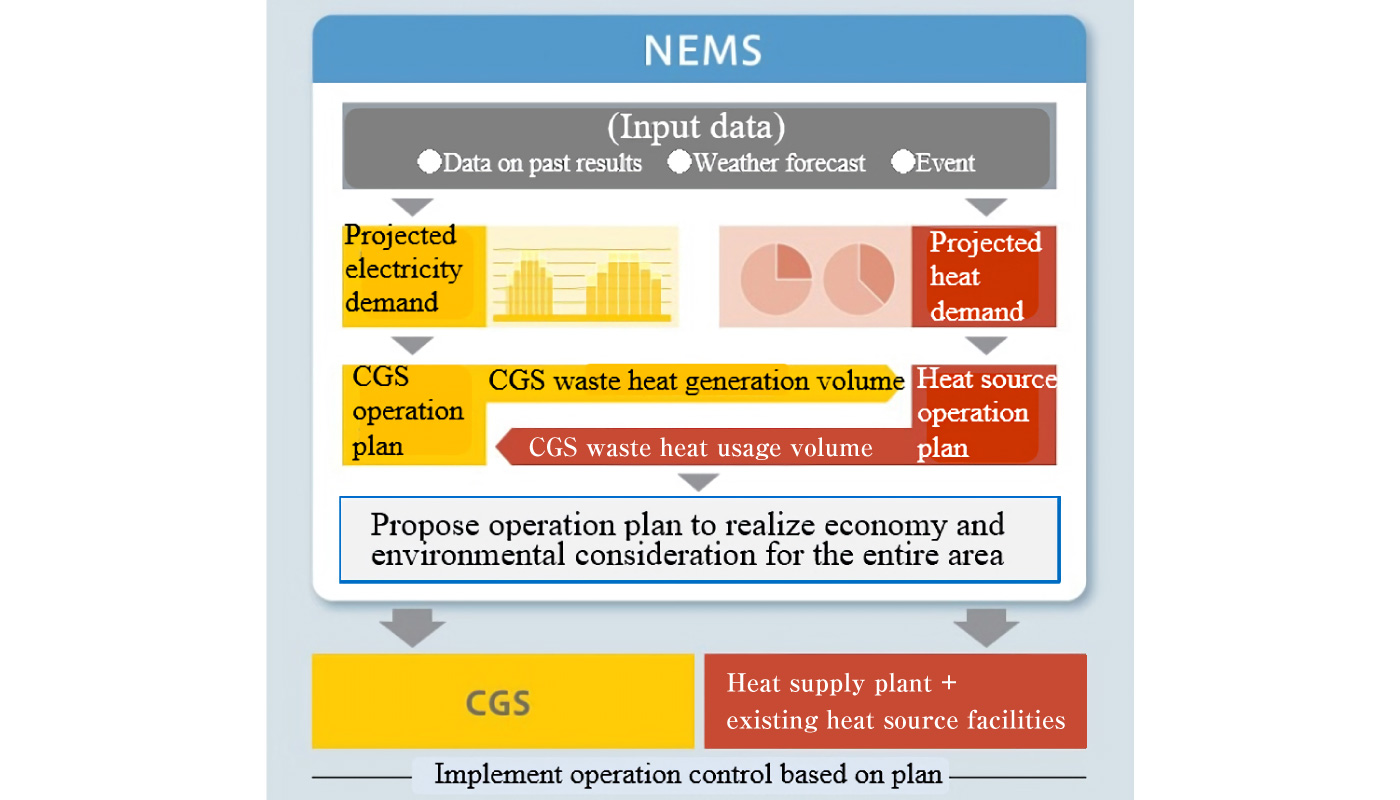

<Nihonbashi Energy Management System>

NEMS projects an area’s load and through optimal operation of a CGS and heat source facility contributes to saving energy and reducing CO2 throughout the entire neighborhood by raising the usage efficiency of waste heat produced by the CGS. Furthermore, due to partial supply using heat source facilities in existing buildings, heat that would have been disposed of during heating demand off-peak times is used effectively to enhance the CGS waste heat use rate during the inter-peak phase, which saves energy and reduces CO2.

Fig. 2. Conceptual Chart of Nihonbashi Energy Management System

Fig. 3. Conceptual Chart of Partial Supply

4. Future smart energy projects

Mitsui Fudosan and Tokyo Gas plan to continue collaborating on smart energy projects in other areas, such as Toyosu Bayside Cross, which is scheduled for completion in the spring of 2020. By leveraging their expertise and deepening and evolving their collaborations, the two companies will create attractive neighborhoods supported by stable energy supplies that are environmentally friendly and resilient to disasters, and build an advanced model of a smart city to communicate within Japan and overseas.

Partner(s)

This project is a joint project with Tokyo Gas Co., Ltd.

Similar Innovation Challenges

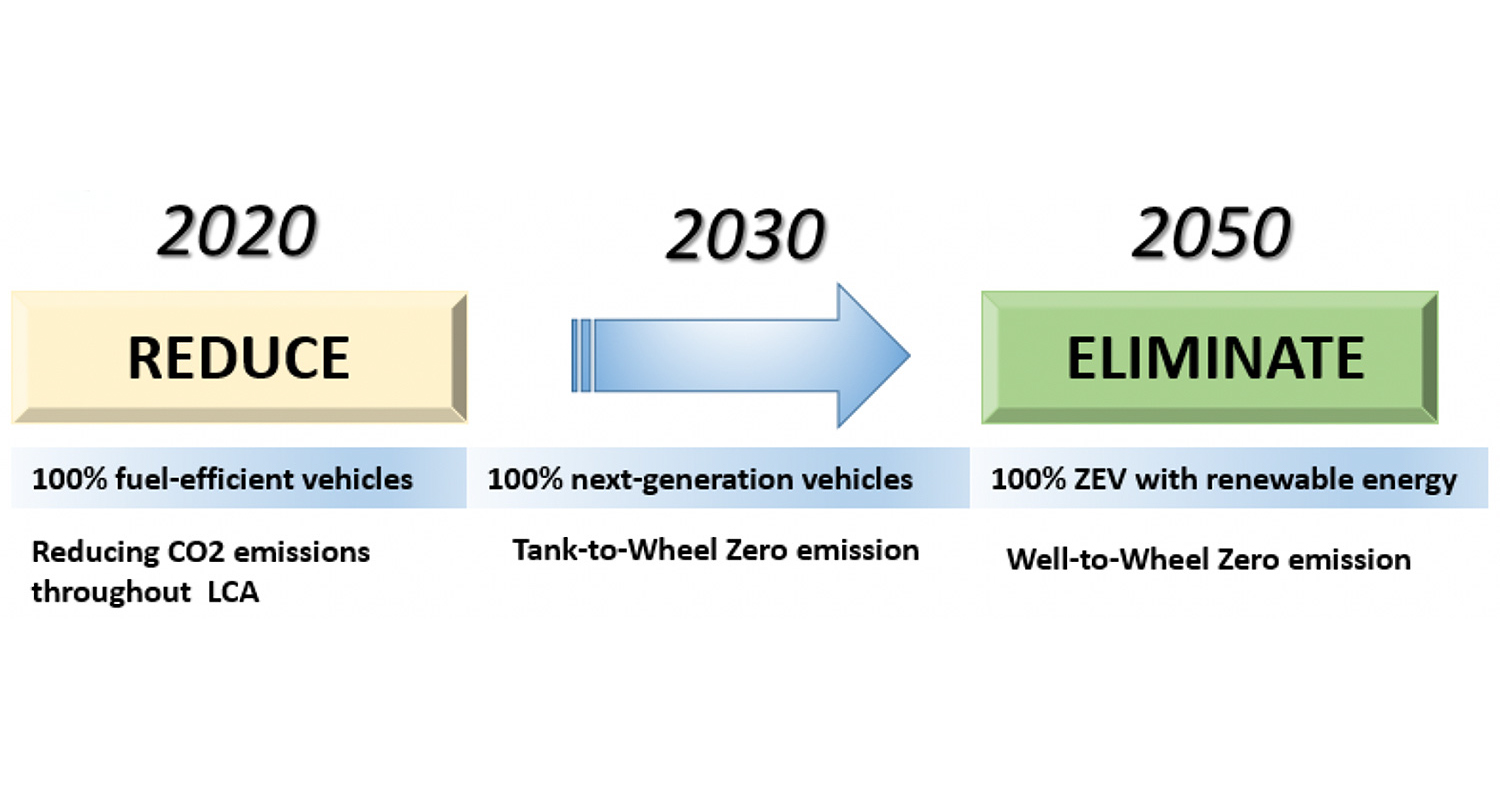

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.