Carbon capture and Storage on board to realize Zero emission Shipping

NYK Line

Outline

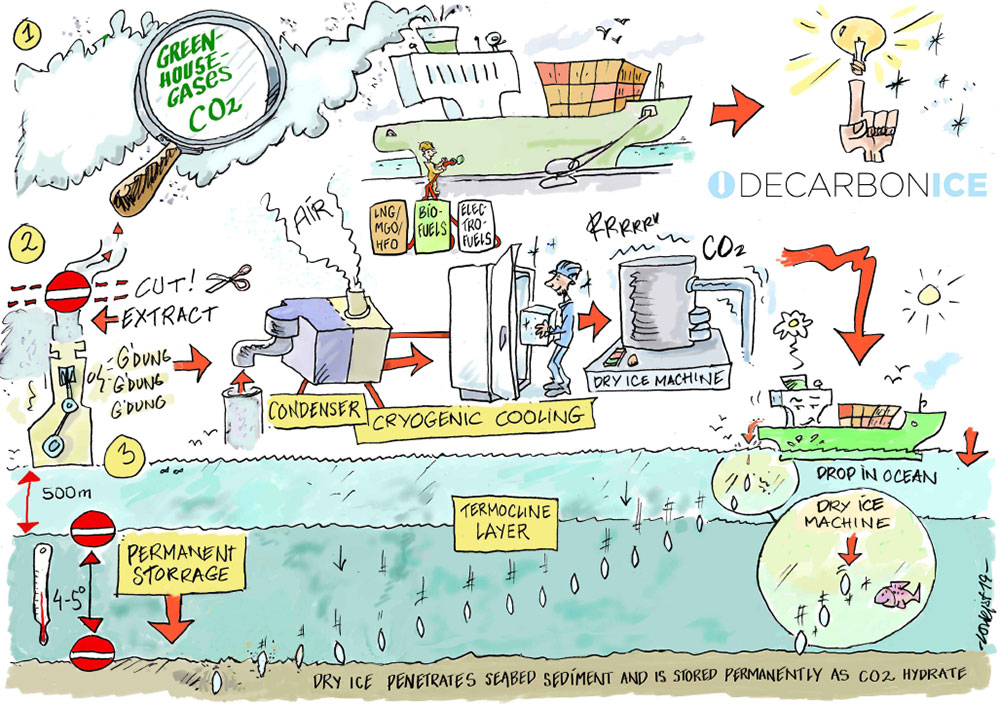

NYK has joined the international DecarbonICE project that will be conducting a feasibility study to capture onboard carbon as dry ice and store it in seafloor sediments. The DecarbonICE project was launched on October 1 by the Denmark-based Maritime Development Center, which has teamed with global shipping companies (including NYK), shipbuilders, and others to conduct a feasibility study on solutions to onboard carbon capture and storage, and to initiate discussions on environmental impact assessments and the IMO-approval process for the technology. The solution builds on known technologies and physical principles and can be used on new buildings and retrofitted into existing ships. When new carbon neutral fuels like biofuels or synthetic fuels (e-fuels) become available, the technology will in combination with such fuels lead to carbon negative shipping, where CO2 is removed from the atmosphere.

Description

NYK has joined the international DecarbonICE project that will be conducting a feasibility study to capture onboard carbon as dry ice and store it in seafloor sediments.

The shipping industry is looking for carbon-free solutions to achieve the IMO 2050 target of a 50% CO2 emissions reduction (compared to the 2008 level). In response, new zero-carbon solutions are being developed around the globe, including alternative low-carbon fuels such as LNG fuel that can be used in place of heavy oil.

The DecarbonICE project was launched on October 1 by the Denmark-based Maritime Development Center, which has teamed with global shipping companies (including NYK), shipbuilders, and others to conduct a feasibility study on solutions to onboard carbon capture and storage, and to initiate discussions on environmental impact assessments and the IMO-approval process for the technology.

During the study, CO2 in the ship exhaust will be captured on board in a cryogenic process and turned into dry ice. It will then be transported into seafloor sediments during normal ship operations. There, the CO2 will be safely and permanently stored as liquid CO2 and CO2 hydrate.

Shipping emits close to 1 billion tons of CO2 each year, of which 80% comes from ships in deep sea trading. Through application of the decarbonICE™ technology, it is the ambition to reduce emissions from deep sea shipping by 90% in a safe, environmentally friendly, and affordable manner.

The solution builds on known technologies and physical principles and can be used on new buildings and retrofitted into existing ships. When new carbon neutral fuels like biofuels or synthetic fuels (e-fuels) become available, the technology will in combination with such fuels lead to carbon negative shipping, where CO2 is removed from the atmosphere.

The NYK Group is dedicated to achieving the SDGs through the group’s business activities and its medium-term management plan “Staying Ahead 2022 with Digitalization and Green.” NYK will continue its efforts to reduce CO2 emissions through initiatives such as the introduction of new technology and fuel conversion.

Partner(s)

Listed alphabetically

Ardmore Shipping Services Corporation

BW Group Ltd.

Clean Marine AS

Daewoo Shipbuilding & Marine Engineering Co., Ltd.

Knutsen OAS Shipping AS

Sovcomflot Ltd.

Teekay Corporation

Vale S/A

Maritime Development Center

Transport Innovation Network

Supplementary information

NYK Line News releases

https://www.nyk.com/news/2019/20191204_01.html

NYK Line Targets and Plans

https://www.nyk.com/english/csr/envi/plan/

decarbonICE™

https://mdc.center/decarbonice-home

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION