Promote research and development to reduce cost and achieve greater durability and efficiency for the widespread use of fuel cell electric vehicles

TOYOTA MOTOR CORPORATION

Outline

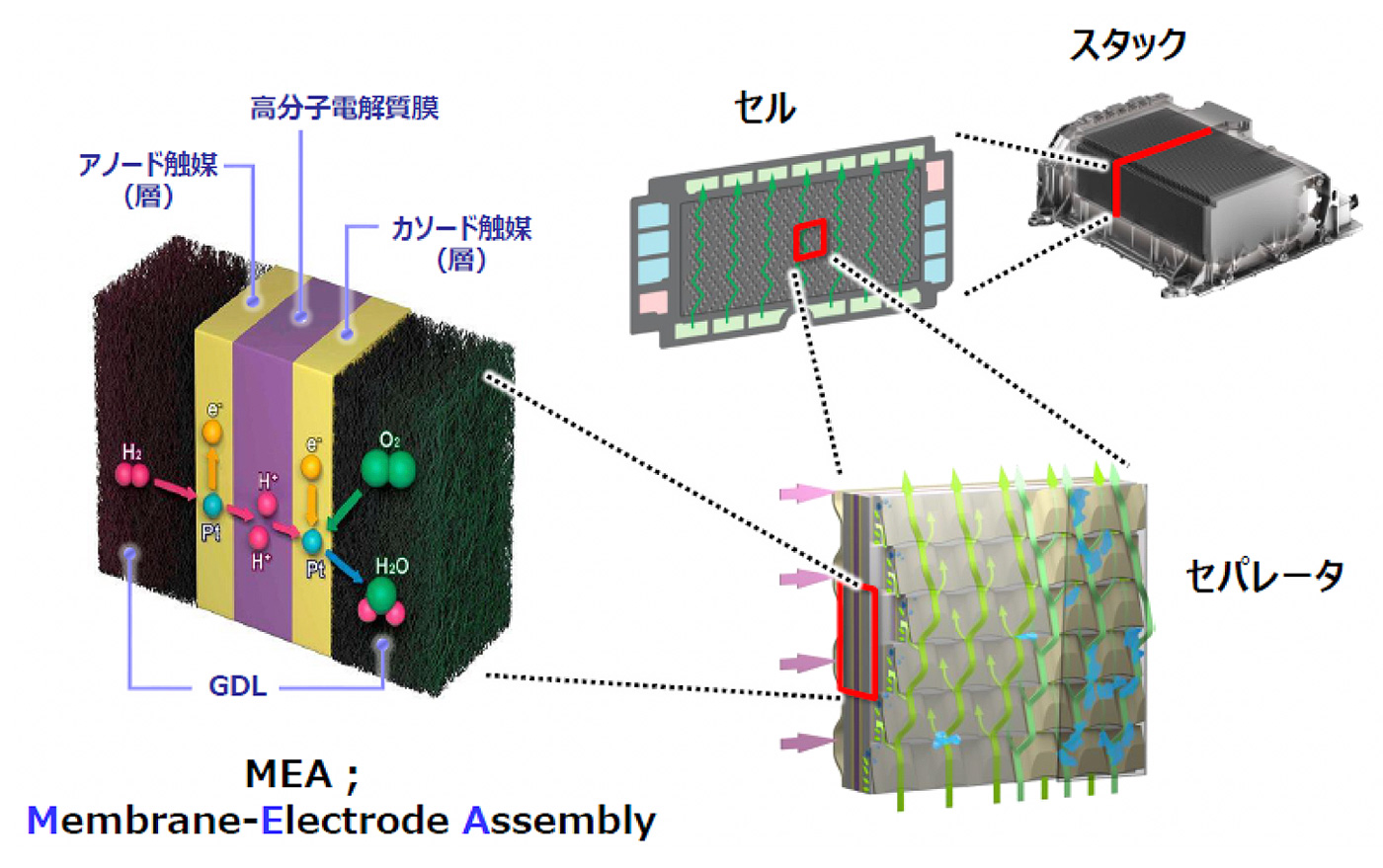

・ For the widespread use of fuel cell electric vehicles (FCEVs), it is necessary to further reduce cost and achieve greater durability and efficiency of the fuel cell system. To be more specific, we will work on research that goes back to the basic in collaboration with academia, such as new material development of electrolyte membrane, catalyst, carbon fibers and others and phenomenon analysis of electrochemical reactions, in order to realize the METI’s “2030 Strategic Roadmap for Hydrogen and Fuel Cells (FC system cost: less than 4,000 Japanese yen per kW; maximum output energy density: 6.0kW per liter; durability of passenger/ commercial vehicles: more than 15 years)” and NEDO’s “Technology Development Goals Around 2040 (FC system cost: less than 2,000 Japanese yen per kW; maximum output energy density: 9.0kW per liter; etc.)”.

・ As an action plan, for the fuel cell system:

(1) electrolyte membrane: develop technology that prevent cross leakage and maintain and improve durability; and

(2) precious metals which is used as catalyst: develop technology that reduce usage and replace current metals with other catalysts while maintaining and improving the performance and durability of the catalyst.

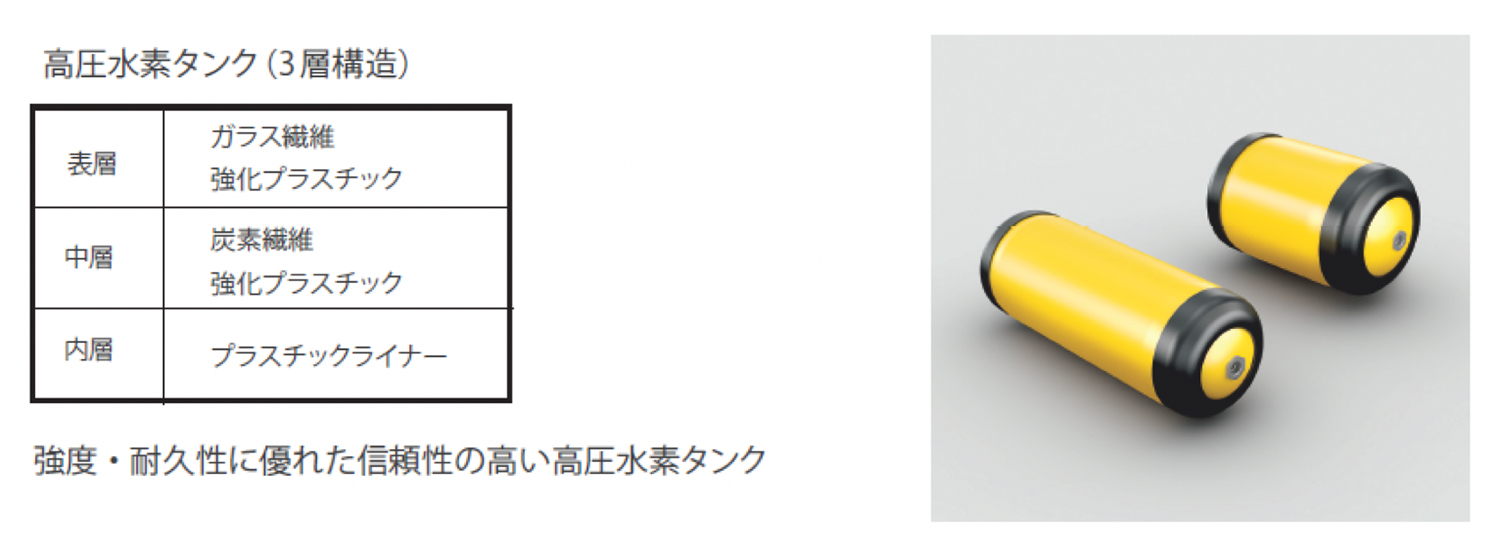

For hydrogen storage system, develop technology that enable effective winding, reduce carbon fiber usage which accounts for most of the onboard hydrogen tank costs and others.

Description

・ Within the fuel cell system of FCEVs, electrolyte membrane is considered to account for the very large part of the cost. Also, since cost of precious metals of the catalyst is considered to account for a significant cost even after mass production of vehicles, research and development to reduce these costs are important. In addition, it is necessary to develop technology for mass production in parallel, in order to establish commercial scale production technology.

・ For hydrogen storage system, it is important to reduce carbon fiber usage which accounts for most of the onboard hydrogen tank costs and develop new materials, and develop mass production technology for raising winding efficiency and shortening resin hardening time and others.

・ In future, it is important to follow up the achievement status of these element technologies and car models deployed, on a regular basis. And in order to support these initiatives, we will establish a multilevel system for technology development collaborated by the industry, government, and academia. For example, automotive manufacturers share the technical information and issues in the noncompetitive and cooperative area, and the universities and research institutions proposes the solution.

Partner(s)

New Energy and Industrial Technology Development Organization (NEDO),

Fuel Cell Cutting-Edge Research Center Technology Research Association (FC-Cubic),

University of Yamanashi, etc.

Supplementary information

https://www.nedo.go.jp/events/report/ZZTSC_100015.html

*Only available in Japanese

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION