Energy-saving using new innovative rechargeable batteries that enable fast charging

Toppan Printing CO., LTD.

Outline

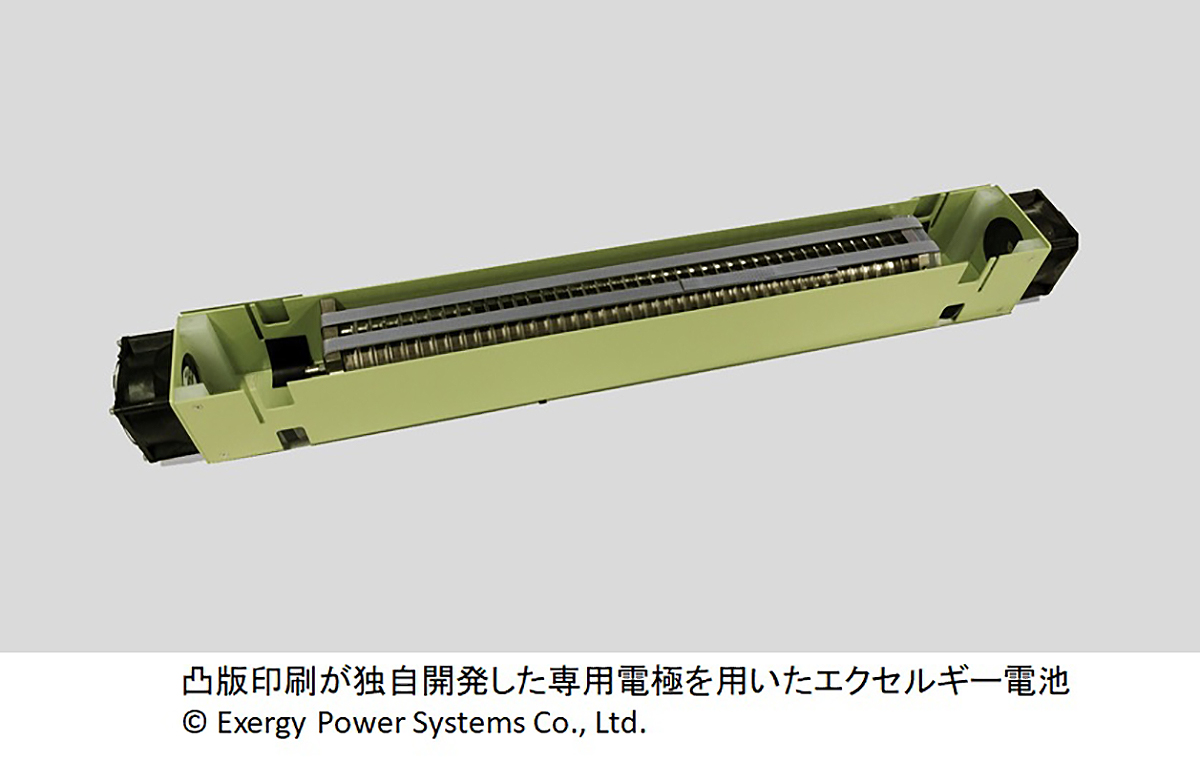

Using specially-designed electrodes developed in-house, Toppan Printing has collaborated with Exergy Power Systems, Inc. to develop the Exergy Battery, a next-generation rechargeable battery.

This battery can be charged/discharged at a high speed of more than 200C (*1), about 100 times the speed of conventional rechargeable batteries. This enables high-output regenerative power charging to be used for cranes and other heavy machinery, something that has been difficult with conventional rechargeable batteries. The use of regenerative power means that significant enhancement in energy efficiency is anticipated due to the reduction in electricity supply compared with conventional power supplies.

*1. C: Unit of charge and discharge rate. 1C indicates a current value that enables full charge/discharge in 60 minutes. The battery we have developed enables full charge/discharge at a rate of 60 minutes/200C=18 seconds.

Description

Against a backdrop of increased global demand for mobile devices, the market for rechargeable batteries, particularly for compact, thin, high-density lithium-ion batteries, is growing rapidly, and the value of the market is expected to exceed \9 trillion in 2025. Demand related to environmental protection, such as electric vehicles, is also expanding at pace.

Due to their combination of power and output time, nickel-hydrogen batteries and lithium-ion batteries are commonly used for automobiles. In the case of forklift trucks and other heavy machinery, several batteries need to be available to increase operating rates because it takes about 8 hours to charge a battery. There are also issues related to deterioration of batteries due to rises in temperature resulting from the time needed to release heat from the inside of conventional rechargeable batteries.

Exergy Power Systems is a venture company established in 2011 and originating from the University of Tokyo. It develops, produces, and provides hydrogen-based rechargeable batteries and fuel cells. Since 2011, when Exergy Power Systems was established, Toppan has worked on joint development and commercial testing of the Exergy Battery to find solutions to challenges faced. As a result, the development of highly durable rechargeable batteries that enable continuous high-speed charging and discharge is in sight, and a capital tie-up is being established via a \500 million capital injection as a foundation for joint commercialization efforts.

Features of the Exergy Battery

・ Enables high-speed charge/discharge

Employs a special battery structure that releases heat generated inside the battery quickly and limits rise in heat to a maximum of 5 degrees, meaning that continuous high-speed charging is possible at 200C, which is 100 times the speed of conventional rechargeable batteries.

・ Highly durable

Durability has been significantly enhanced by enclosing hydrogen inside the battery to prevent deterioration of the electrodes caused by oxygen. This enables a high-rate, continuous 50C charge/discharge cycle life of more than 150,000 times, which is 10 times that of conventional rechargeable batteries.

・ Floating charging is possible

Floating charging without overcharging is possible even without a control device because the battery voltage of the battery can be set at the same value as the charge voltage. This means that the battery can be used as a backup or uninterruptable power supply.

・ Uses safe materials

The nail penetration test (*2) performed as a safety test for rechargeable batteries is not necessary because no lithium or organic materials are used in the battery.

*2. Nail penetration test: A test in which a nail is used to piece the battery to check that it does not catch fire or explode.

・ Helps to increase energy efficiency and operating rates for heavy electrical machinery

The use of regenerative power enables a significant reduction in power consumption for such machinery as cranes. Fast charging also considerably reduces charging time, helping to raise operating rate per machine for heavy electrical machinery.

About the electrodes developed by Toppan Printing

Electrodes have been developed by leveraging Toppan Printing’s material design expertise and coating technologies. Specifically, printing technologies have been applied to coat nickel-based material with an original conductive ink developed by Toppan Printing as the electrode material. The battery cell has been formed by layering positive and negative electrodes and the separator.

Partner(s)

Exergy Power Systems, Inc.

EP, Inc.

Supplementary information

Other Innovation Challenges

Creating communication infrastructure to encourage behavioral changes at home

Toppan Printing CO., LTD.

Development of low cost, high-durability MEA targeting the further expansion of fuel cell use

Toppan Printing CO., LTD.

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)