The reduction of CO2 emission by recycling films

TOYOBO CO., LTD.

Outline

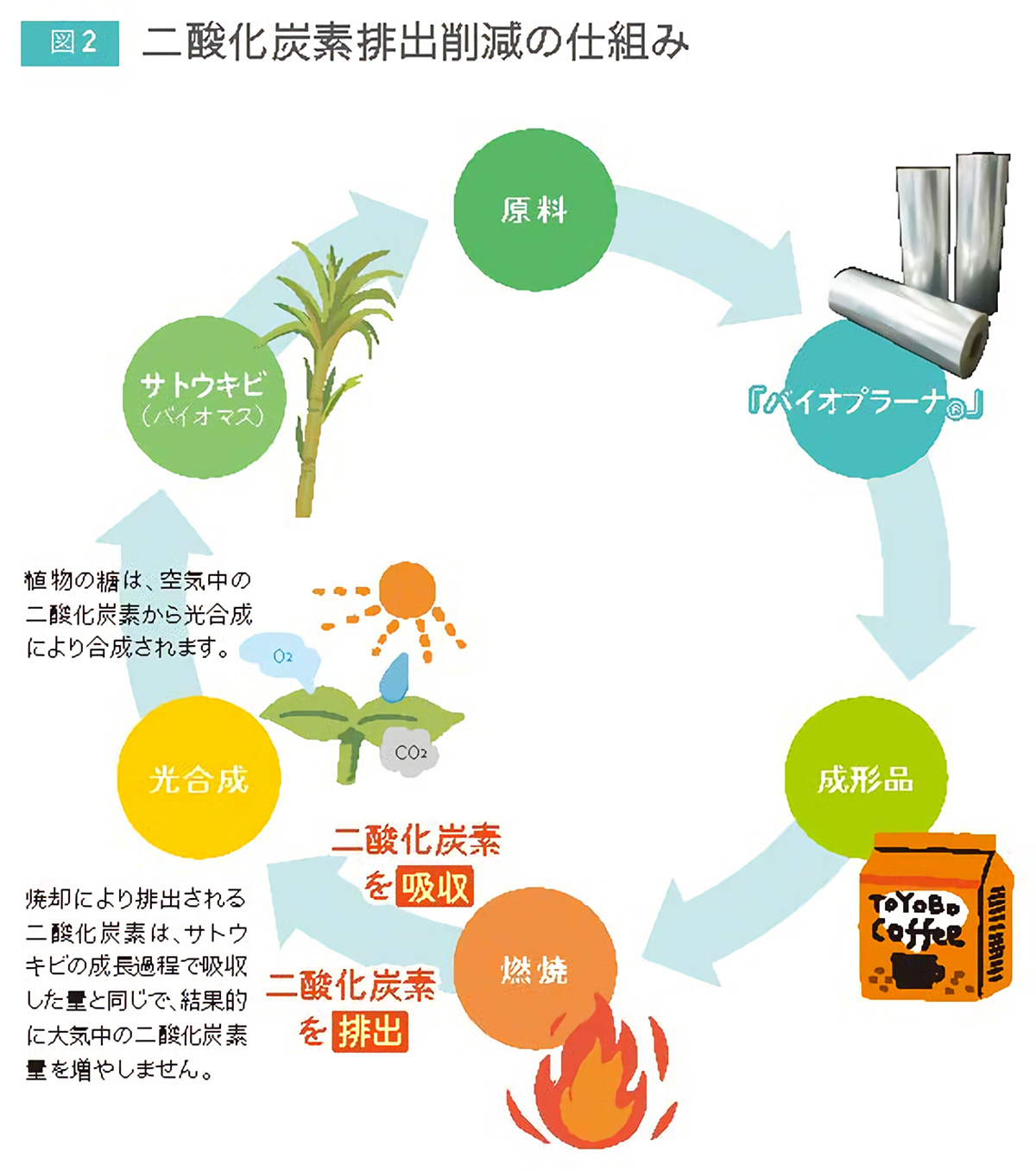

Large amount of disposed plastic materials are being incinerated, and CO2 emitted by incineration could be one factor of global warming. The entire industry has been making efforts to reduce CO2 emission, in which recycling has been considered as solution.

We sell PET films used in production process of electric and electronic materials. They are not assembled into manufactured parts or products, but are discharged as industrial waste from production process of parts or products.

Currently, the PET films used in such production processes are not utilized effectively. However, they can be recycled and reused in many ways, which leads to reduction of CO2 emitted during disposal and incineration. When 10K tons of PET films for production process are recycled a year, 60K tons of CO2 emission can be reduced.

Description

1. Achievement target for the challenge

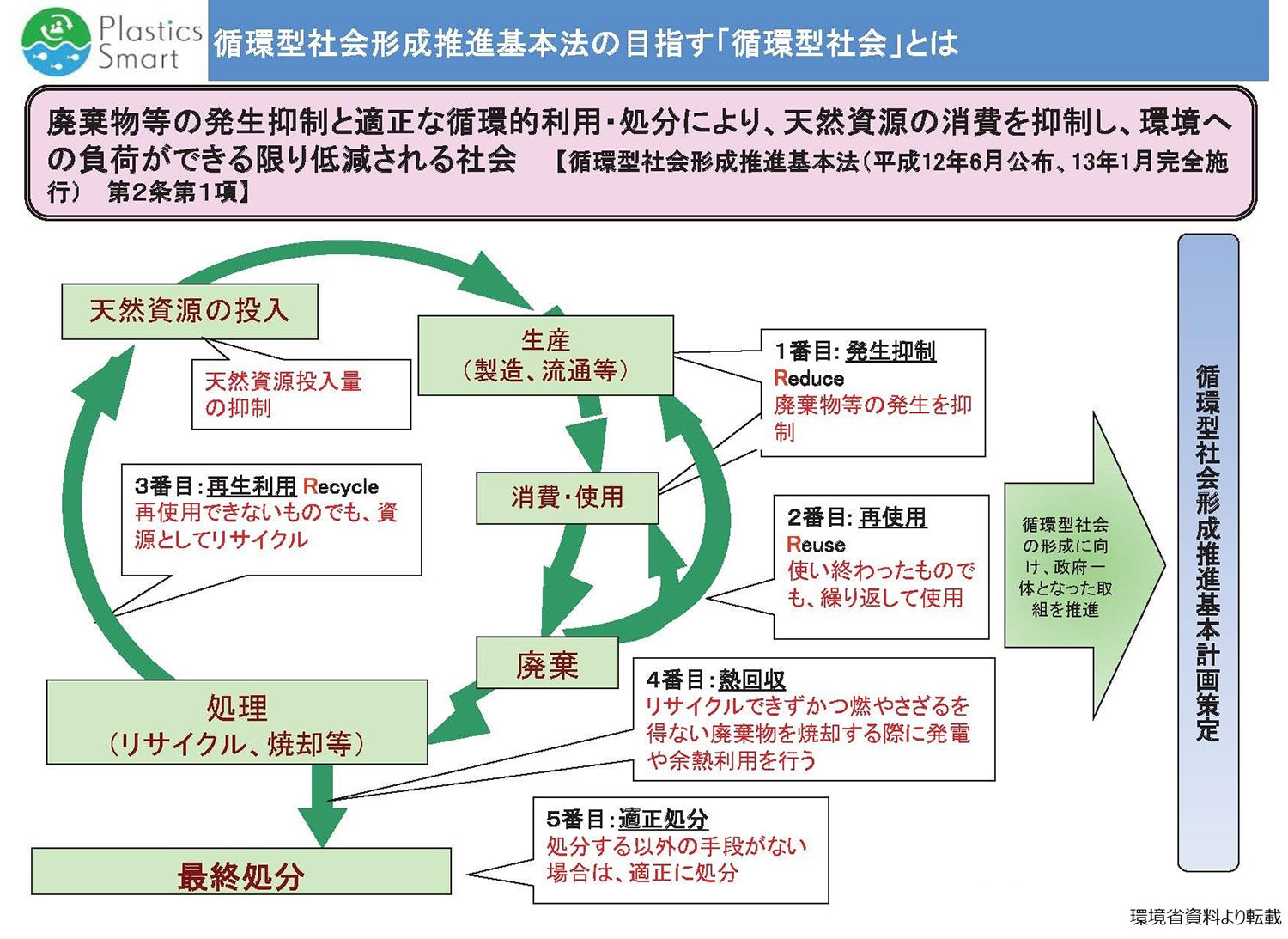

• In accordance with “Plastics Material Cycle Strategy” by the government.

By 2030, the ratio of products that contain recycled resin is to be 60%.

By 2050, all products are to be replaced with those that contain recycled resin.

2. Issues to be solved to overcome the challenge

• Technical issues have been solved until now. There are issues regarding price in comparison with the current products made with virgin resin.

• Unlike food packages, recycling of collected films is relatively easy. However, the amount that can be collected is smaller than food packages. Therefore, scale effect will be necessary for economic efficiency, in such a way as collecting PET films also from other manufacturers.

3. Our concrete actions

• Collaboration with other companies could be necessary, for which we are going to search for partners and make offers to them.

4. Quantitative effects when the challenge is overcome

• We use an assumption that used films collected from our customers are cleaned by surface washing, and are sold again as recycled materials.

• Based on a material document, 1 t of PET films emit 3.9 t of CO2 for production and 2.3 t for incineration (6.2 t−CO2/t in total). When used films are recycled with 1.4 t−CO2/t of energy amount and then reused directly, the CO2 amount for production (1.2 t−CO2/t) can also be reduced. Therefore, 1 t of products can reduce 6.0 t of CO2.

• By recycling and reusing 10K tons of products a year, CO2 emission can be reduced by 60K tons compared with the current amount.

Supplementary information

Other Innovation Challenges

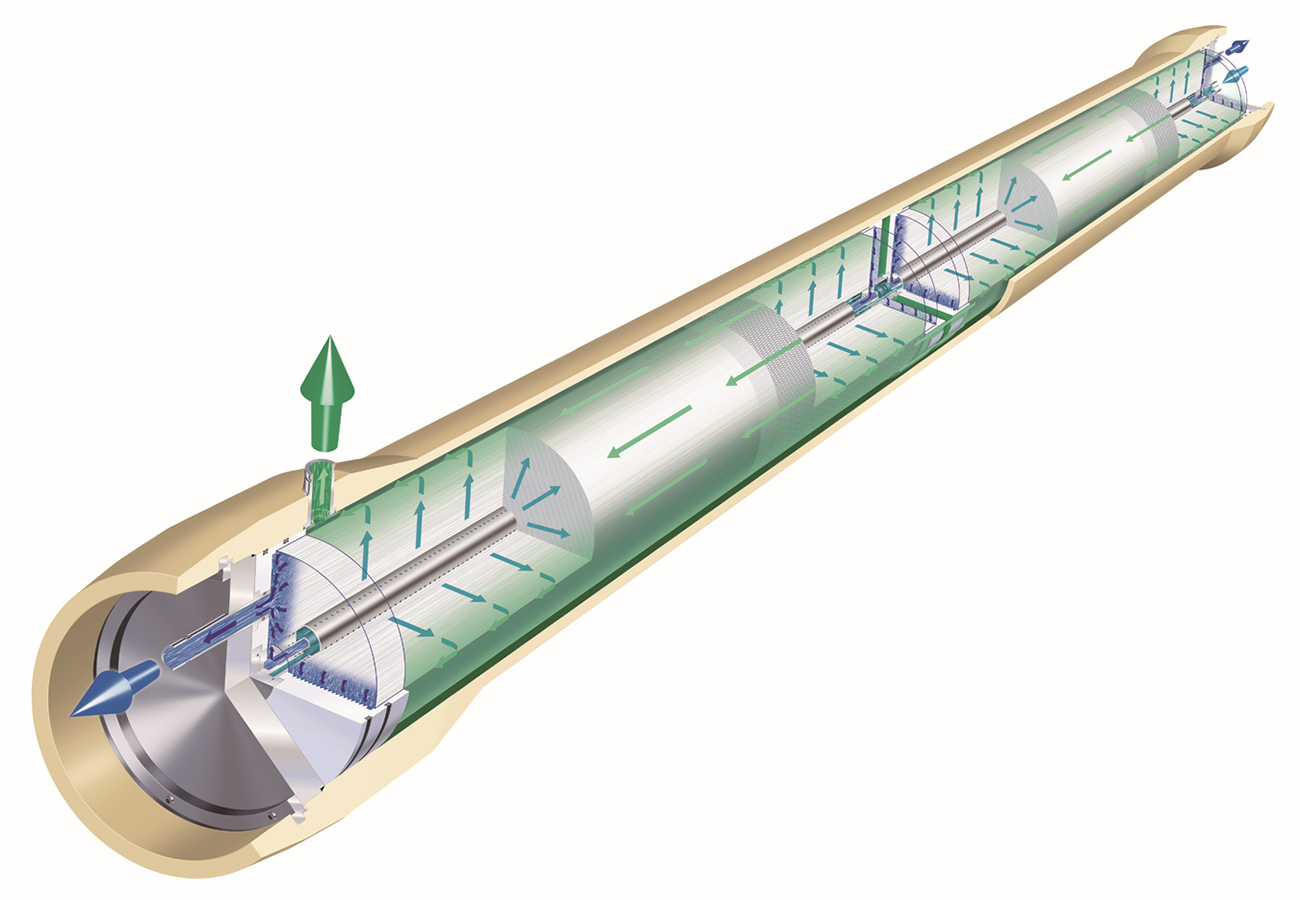

Development and practical application of CO2 separation membrane and system that have both high performance and practicality

TOYOBO CO., LTD.

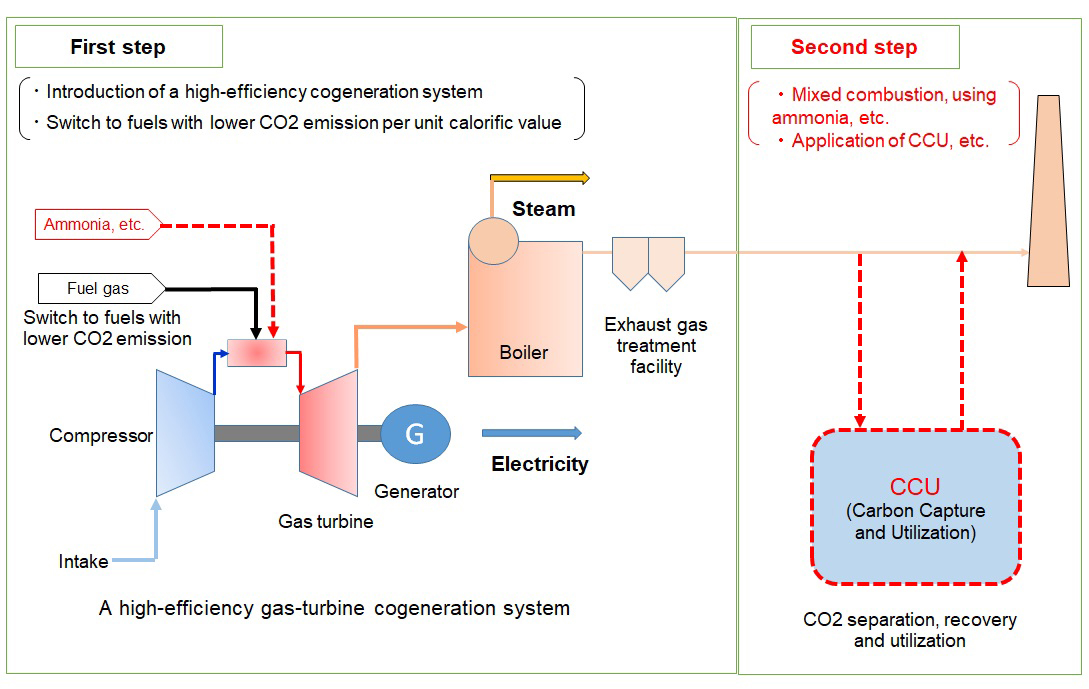

Fuel conversion of boiler and private power generation equipment

TOYOBO CO., LTD.

Recycling of PET bottles~the reduction of CO2 emission by shortening processing of PET bottles

TOYOBO CO., LTD.

The develop of a forward osmosis membrane (FO membrane) for osmotic pressure power generation using high salt concentration geothermal water

TOYOBO CO., LTD.

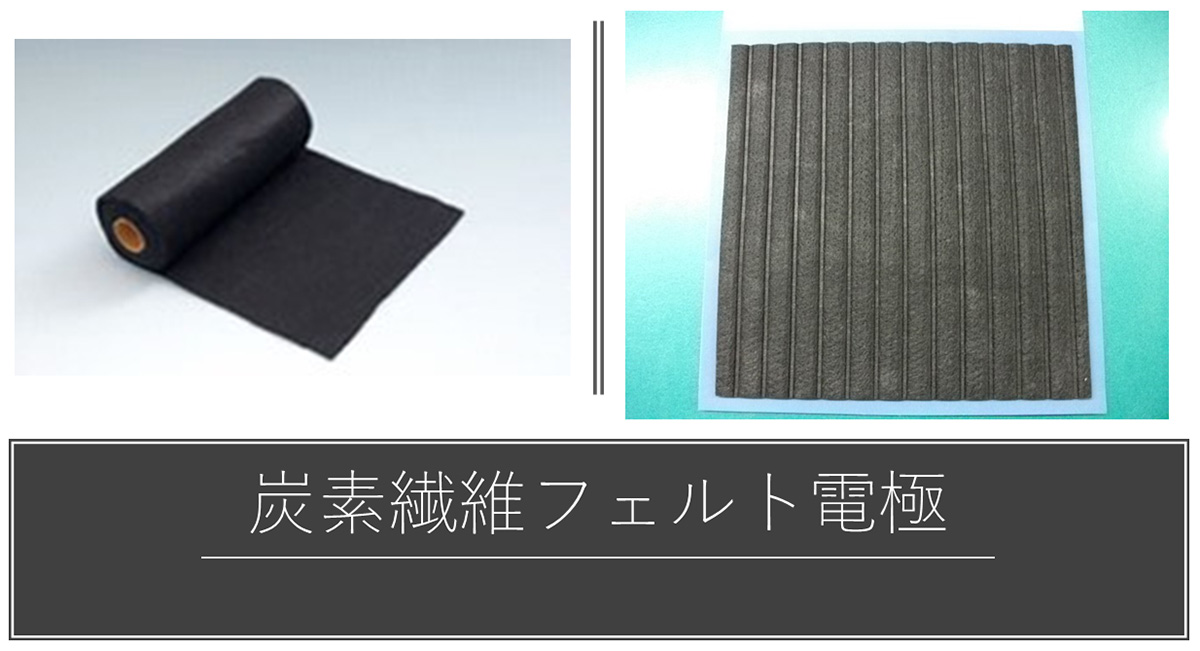

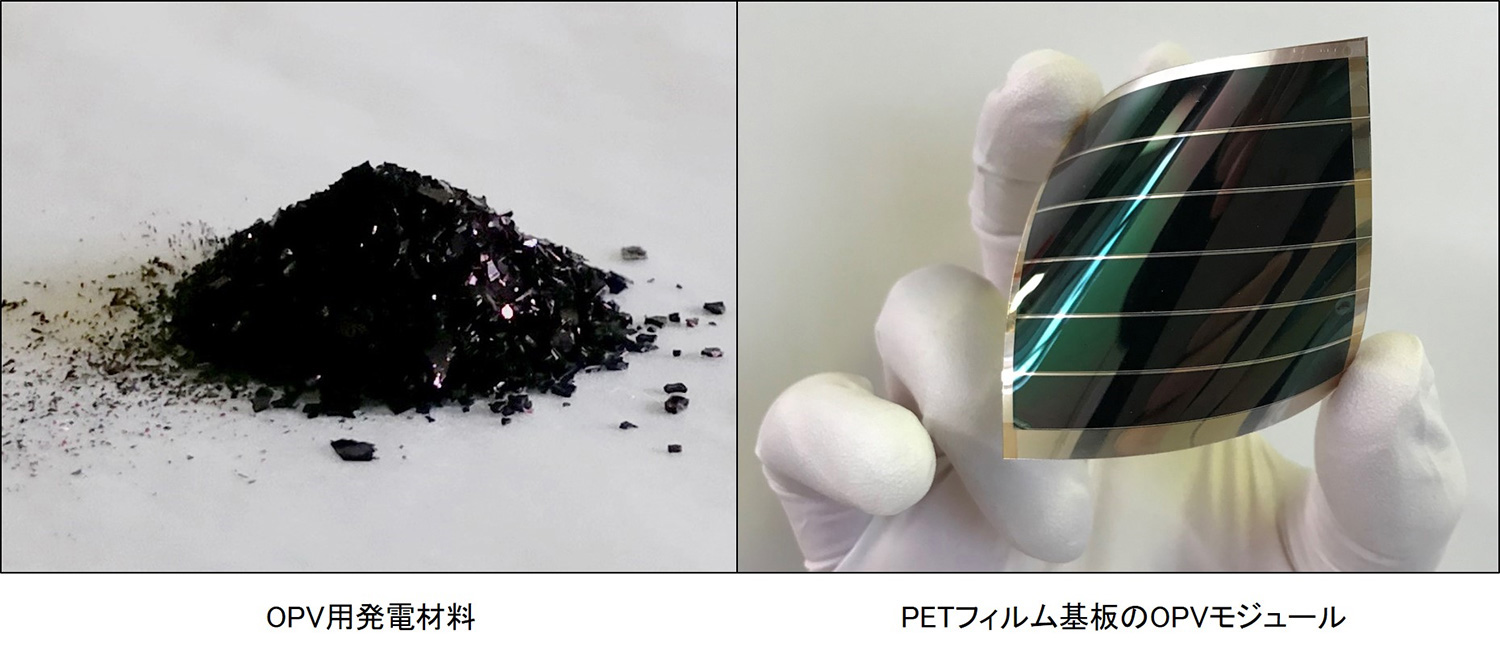

The develop of high performance carbon materials for the dissemination of secondary battery which is essential for utilization of renewable energy

TOYOBO CO., LTD.

The development of higher seawater concentration by the new hollow RO membrane

TOYOBO CO., LTD.

The recycle of PET bottles ~The reduction of CO2 emission by replacing recycled yean,which was made from PET bottles

TOYOBO CO., LTD.

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

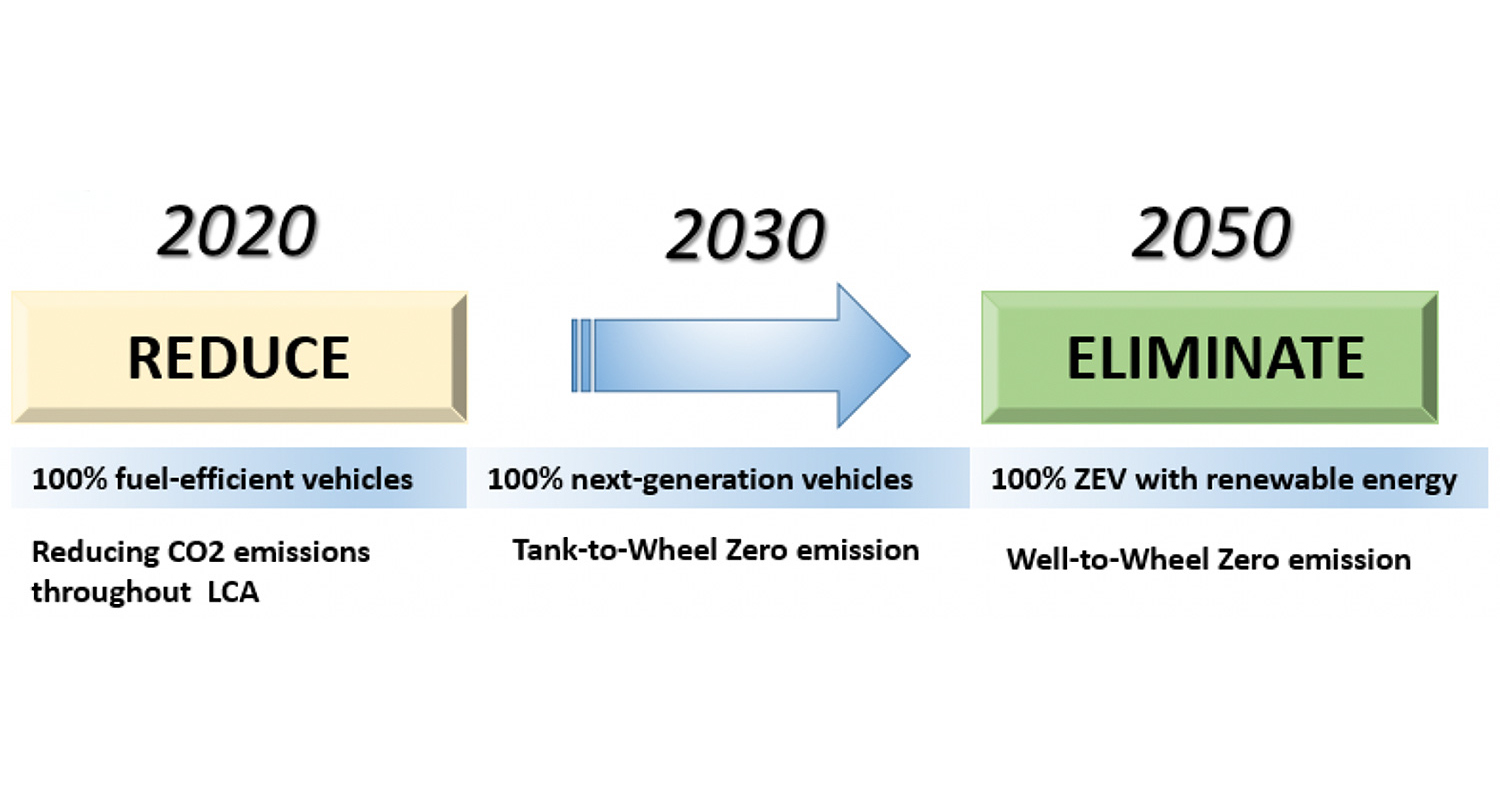

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.