Development of CO2-Free Hydrogen Filling Stations for Fuel Cell Forklift

TAIYO NIPPON SANSO Corporation

Outline

Taiyo Nippon Sanso Corporation (“TNSC”) is developing CO2-free hydrogen filling stations for fuel cell forklifts (“FCFL”) as a technology for commercial vehicles to operate without emitting greenhouse gases. The system under development uses electricity generated by solar panels to power a water electrolyzer hydrogen generator that produces hydrogen used as fuel for FCFLs. The volume of hydrogen produced using solar power changes depending on the weather and sunlight hours. The number of FCFLs introduced also differs, depending on plant size. A system has been installed to store hydrogen produced with flexibility under these fluctuating conditions by pressurizing it using a compressor and storing it in a hydraulic accumulator. To respond to the abovementioned varying conditions, our system development will incorporate equipment that uses AI and IoT in the future, and will contribute to global initiatives aimed at realizing a carbon-free society.

Description

In North America, the number of FCFLs in operation already exceeds 15,000, and as more are introduced domestically in the future, demand for hydrogen filling stations is expected to increase. TNSC installed a FCFL CO2-free hydrogen filling station at the Kawasaki Mizue Production Facility in February 2020 and has started operating FCFLs.

TNSC is considering a weather forecast-based energy management system and collecting system data projecting FCFL filling demand to effectively control the volume of hydrogen production, and is working to optimize a unified operation system that will produce hydrogen, pressurize, hydraulically accumulate and supply the hydrogen produced with a view to starting commercial use in two years.

1. Specifications

(1) Capable of consecutive supply of hydrogen gas to five FCFLs

(2) Water electrolyzer hydrogen generator with hydrogen production capability of 5 Nm3/hr

(3) Compressor with hydrogen compression capacity of 5 Nm3/hr

(4) Hydraulic accumulator with 2 steel containers pressurized at 45 MPa capable of holding 300 liters

(5) Units contain all necessary devices, saving energy for local construction

(6) Control hydrogen production volume in response to change in sunlight hours

(7) Filling control is automatically selected upon recognition of an IC tag on an FCFL

(8) Automatic filling with filling management using employee ID cards or touch panel operations

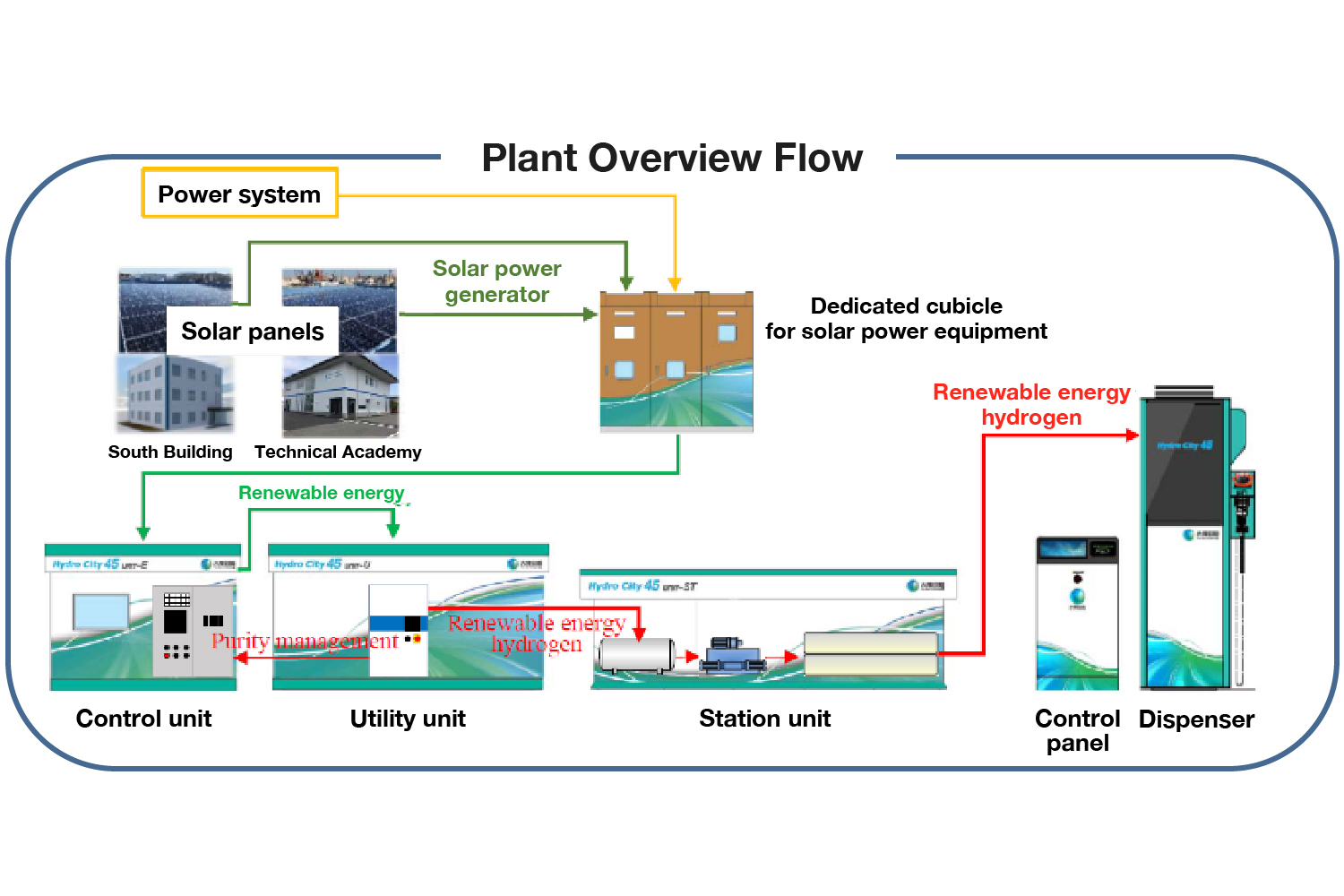

2. Unit Composition

(1) Solar panels

(2) Dedicated cubicle for solar power equipment

(3) Control unit

(4) Utility unit

(5) Station unit

(6) Dispenser and control panel

3. System Flow

(1) Generate power through the solar panels

↓

(2) Produce hydrogen gas in the water electrolyzer hydrogen generator

↓

(3) Pressurize the hydrogen gas in the compressor

↓

(4) Accumulate at pressure of 45 MPa in the hydrogen pressure accumulator

↓

(5) Fill the FCFL with hydrogen gas at 35 MPa

Partner(s)

(1) TOYOTA L&F KANAGAWA Co., Ltd., etc.

(2) Ministry of the Environment (subsidy)

(3) Kanagawa Prefecture (subsidy)

(4) City of Kawasaki

Supplementary information

(1) For more details, refer to the FCFL CO2-free hydrogen filling system catalog (Japanese)

(2) For more details, refer to the TNSC website (only in Japanese)

https://www.tn-sanso.co.jp/jp/news/detail.html?id=3314

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)