Biomass energy utilization

Daio Paper Corporation

Outline

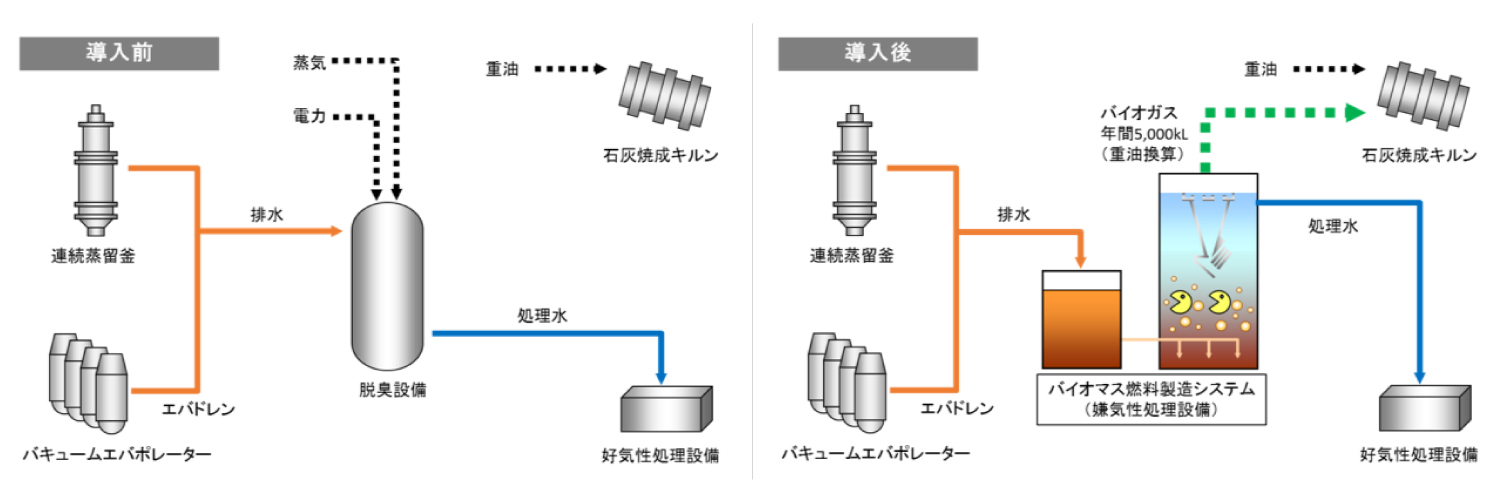

The wastewater generated from the production process of kraft pulp, which is a raw material for paper, contains methanol from wood resins. Biogas (gas derived from biomass, which is mainly composed of methane generated when organic matter is fermented) is extracted from the process wastewater and used as a substitute fuel for fossil fuels.

In October 2020, we plan to install one of the largest anaerobic treatment facilities in Japan at our Mishima Mill. In addition to reducing the load on existing wastewater treatment, we can also expect an annual reduction in heavy oil consumption of approximately 5,000kL and in CO2 emissions of approximately 15,000t.

Description

The paper industry has long used biomass fuels, waste liquor of pulp cooking (black liquor), wood bark, which cannot be used as a raw material, and paper sludge, which is produced when used paper is recycled, as fuels before global warming has been recognized as a worldwide critical issue. We have also started operation of a biomass boiler fueled mainly by construction and demolition waste, ahead of the Paper industry.

In addition to these conventional biomass fuels, a new biomass fuel production facility will be installed at our Mishima Mill in October 2020 to extract biogas from wastewater generated from the kraft pulp production process. This facility will be one of the largest anaerobic treatment facilities in Japan, utilizing the technology of the anaerobic treatment system (bioimpact) of Sumitomo Heavy Industries Environment Co., Ltd.

The wastewater generated from the production process of kraft pulp, which is a raw material for paper, contains methanol and odor component. Conventionally, wastewater, which contains methanol, is not used effectively, and had to use much energy to remove an odor component from the wastewater.

In this project, biogas extracted at this anaerobic treatment facility is used effectively as a fuel alternative to heavy oil used in the lime kiln at our Mishima Mill. This project is expected to reduce environmental impact by reducing CO2 emissions (approximately 15,000 tons per year) and reducing the load on existing wastewater treatment.

This project has been adopted by the Ministry of Economy, Trade and Industry as a leading case for the use of renewable energy as an auxiliary project for renewable energy operations. It is also approved as one of the promotion projects in the Ehime Prefecture Biomass Utilization Promotion Plan. This is a project to be promoted by the public and private sectors together.

We are also planning to further reduce heavy oil consumption by combining the biogas extracted from this facility with LNG.

DAIO PAPER Group will continue its efforts to reduce environmental impact through the effective use of renewable energies.

Partner(s)

Ministry of Economy, Trade and Industry

Ehime Prefecture

Sumitomo Heavy Industries Environment Co., Ltd

Supplementary information

Other Innovation Challenges

Development of manufacturing process and application of Cellulose nanofiber

Daio Paper Corporation

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION