Utilization of Sewage Sludge Solid Fuel in Regions

SATO KOGYO CO.,LTD.

Outline

• With the spread of biomass power generation as renewable energy for decarbonization, limitations in the domestic supply and the like of resources such as timber from forest thinning for use as fuel have become an issue. On the other hand, with respect to sewage sludge, which is an organic resource like timber from forest thinning, most of it is still incinerated or subjected to other treatment as waste instead of being converted into energy.

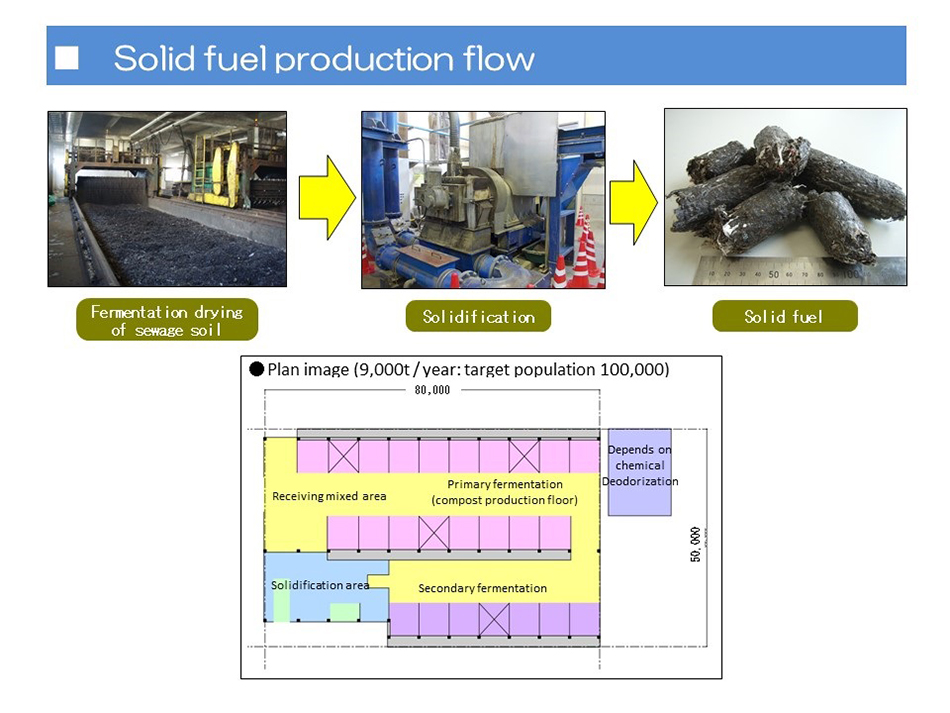

• Considering this situation, technology for converting sewage sludge into solid fuel is being developed. In this technology, sewage sludge, which is an organic resource generated in regions, is dried using fermentation heat in a composting system that does not depend on fossil fuels or the like, and converted into solid fuel by mixing it with waste such as waste plastics and wood. We will work to achieve a decarbonized society by promoting conversion of sewage sludge into biomass fuel using these technologies as a fuel supply business. In these efforts, we will aim to curb excessive use of wood resources and supply carbon-neutral fuels that enable local production for local consumption of organic resources in order to establish a recycling-based inclusive local society that will reproduce favorable effects on local employment and the economy.

Description

○ Challenges that should be overcome to make the efforts successful

• The technology for converting sewage sludge into solid fuel has been developed technically to a certain level. However, viewed in terms of a fuel supply business, there are some limitations to activities mainly performed by individual business operators in terms of total coordination of operations such as ensuring supply sources of sewage sludge and fuel sales destinations as well as coordination among related parties for processing costs, fuel sales prices, and the like.

• Additionally, due to the increased use of biomass power generation in the feed-in tariff scheme, the amounts of timber from forest thinning in Japan and imported PKS fuels have increased, causing emissions of greenhouse gases generated by the transfer of fuel over a wide area as well as country risks (increased supply cost risk, and so on).

• To promote biomass energy, from the perspective of a society based on local production for local consumption, there is a demand for business models that take into account the energy supply and demand balance and fuel supply capacity in individual regions.

○ Our specific actions

• Performing activities for commercialization of a specific energy supply model based on local production for local consumption through discretionary industry-academia collaborative research activities after sharing the challenges and issues in the region among them, using regions in which development of biomass power generation has been successful as models (first step: about two years; target 2022)

• Launching a pilot project to examine its economic efficiency and the like (second step: about three years; target 2025)

• Developing model projects based on local production for local consumption as an alternative to conventional biomass boiler projects: advanced in several locations (third step: five years; target 2030)

○ Objectives of the efforts

• Development (2022): Establishing indicators of dissemination of technology and the like for the model projects (efficient indicators of energy consumption scales and amounts of generated sewage sludge for the dissemination of the projects)

• Practical application (2025): Conducting a pilot project (e.g., population size of about 10,000 to 50,000)

• Cost: Target cost of solid fuel production using dehydrated sludge: 10,000 to 15,000 yen/t

Reference: Conventional biomass fuel procurement costs (yen/t)

Imported chips: 20,000 to 22,000

Imported pellets: 20,000 to 22,000

PKS: 10,000 to 12,000

Source: Japan Woody Bioenergy Association

○ Quantitative effects in a case in which the efforts are successful

Example: CO2 emissions reduced by production of solid fuels: 661 t-CO₂/year/processing population of 50,000

Reference (preliminary calculation example)

• Dehydrated sludge generated by a processing population of 50,000 => 4,000 t/year (assuming 0.08 t/person)

• CO₂ emissions in a case in which solid fuels are produced by using 4,000 t of dehydrated sludge

(Comparison with a case in which all amounts of sewage sludge are incinerated)

• Case of incineration processing

Amount of fuel oil A consumption: 197 kl => CO₂ emissions: 534 t-CO₂/year

Amount of electricity consumption: 1,089 MWh => CO₂ emissions: 599 t-CO₂/year

=> 1,133 t-CO₂/year in total

• Solid fuel production* => In a case in which fuels are used (carbon-neutral)

Amount of diesel fuel consumption: 20 kl => CO₂ emissions: 52 t-CO₂/year

Amount of electricity consumption: 764 MWh => CO₂ emissions: 420 t-CO₂/year

=> 472 t-CO₂/year in total

• CO₂ emissions reduced by solid fuel production:

1,133 − 472 = 661 t-CO₂/year/processing population of 50,000

Supplementary information

Similar Innovation Challenges

Accelarating the penetration of renewable energy resources with “Open Energy System”

Sony Group Corporation

Achieving net-zero carbon emissions from plant factories using full artificial lighting

Taikisha Ltd.

Advanced technology for buildings providing energy-saving and comfortable indoor environment (under Net Zero Energy condition)

Mitsubishi Electric Corporation

AI control reduces base station power consumption by up to 50%

KDDI CORPORATION