Development of construction / mining equipment to achieve zero CO2 emissions at customer sites

Komatsu Ltd.

Outline

Komatsu has developed a battery-powered mini excavator, designed to set the course for next-generation construction equipment, and has achieved “zero CO2 emissions” during its operation. Built upon the technologies cultivated through the creation of hybrid construction equipment and battery-powered forklifts, the mini excavator is environment- and human-friendly machine equipped with a newly developed charger and high-voltage transformer, which enables it to achieve “zero CO2 emission” and significantly reduced noise pollution in working, while demonstrating equivalent excavating capacity to that of engine-powered excavators with the same output. In the future, we will further improve the performance of battery-powered excavators and promote the electrification of other construction and mining equipment, aiming for zero CO2 emissions at customer sites.

Description

The main bulk of CO2 emissions produced throughout the lifecycle of our construction equipment is centered on product operation, during which approximately 90% of emissions are produced. Since construction machinery requires high output and a longer working time, the battery-powered machines have not yet been widely realized in practical use. Under this situation, Komatsu has developed a battery-powered mini excavator, designed to set the course for next-generation construction equipment, and has achieved “zero CO2 emissions” during its operation. It was unveiled at bauma 2019, an international trade fair for construction equipment held in April 2019 in Germany, and sales in market has been launched in March 2020 with the name of “PC30E-5”.

Built upon the technologies cultivated through the creation of hybrid construction equipment and battery-powered forklifts, the mini excavator “PC30E-5” is environment- and human-friendly machine equipped with a newly developed charger and high-voltage transformer, which enables it to achieve “zero CO2 emission” and significantly reduced noise pollution in working, while demonstrating equivalent excavating capacity to that of engine-powered excavators with the same output. These features will no doubt prove to be valuable in construction projects at hospitals, schools and in residential areas, where it was previously necessary to take steps to mitigate exhaust and noise pollution, in addition to tunnels, which could fill with exhaust gas. This excavator uses the easy maintenance battery which powers the popular Komatsu FE-series electric forklift trucks. When fully charged, this battery enables two to six hours* of operation. It also allows for quick charging, for example, during a lunch break, extending the available working hours. (*Hours of work vary depending on jobsite and machine-operating conditions.)

In the future, we will further improve the performance of battery-powered excavators and promote the electrification of other construction and mining equipment, aiming for zero CO2 emissions at customer sites.

Supplementary information

Press Release : “Launching PC30E-5 Electric Mini Excavator in Japan”

https://home.komatsu/en/press/2020/product/1205405_1842.html

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

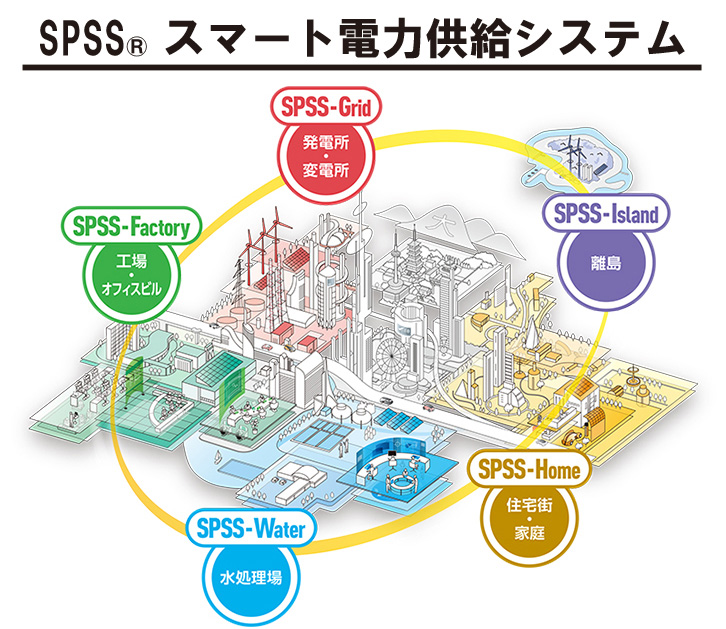

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

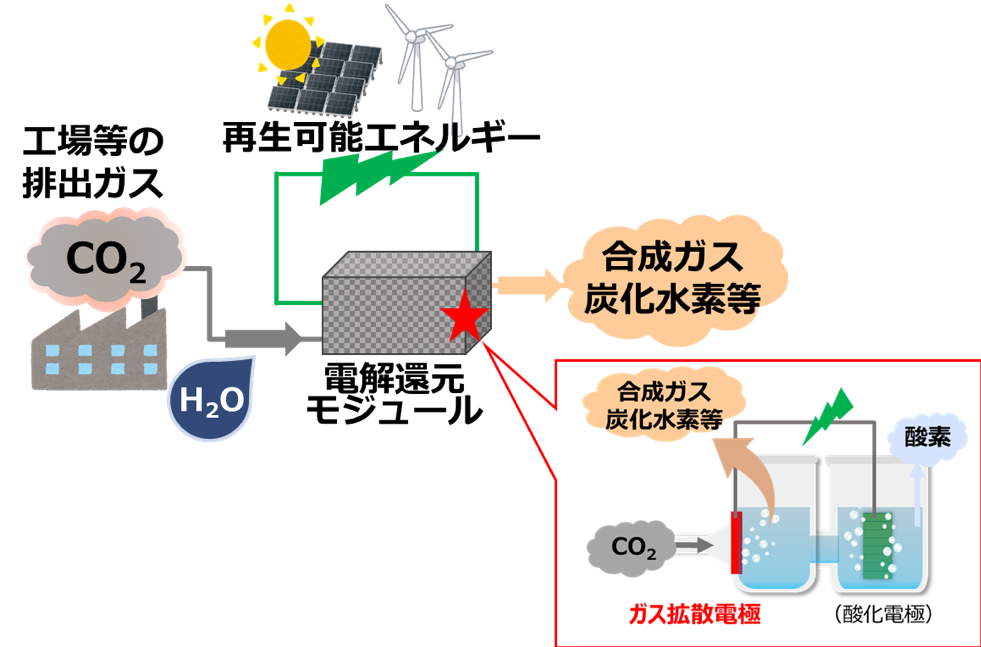

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)