GHG emission reduction by recycling-based production

AJINOMOTO CO.,INC.

Outline

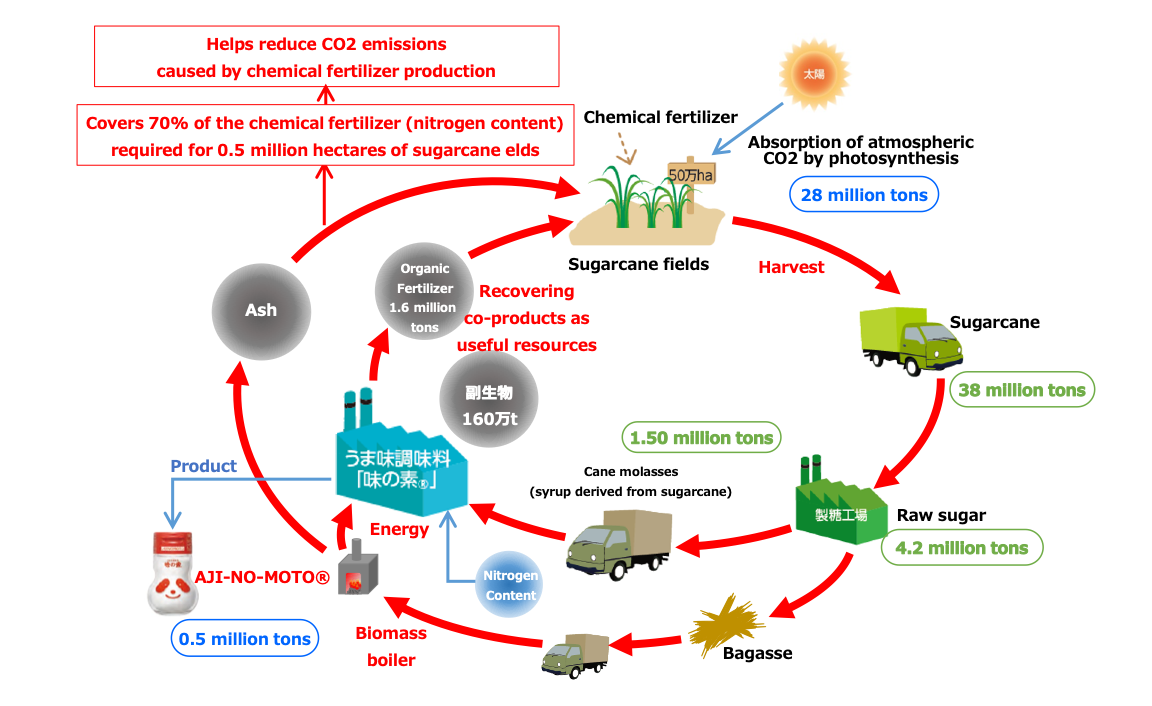

The Ajinomoto Group manufactures amino acids using a recycling-based production named “Biocycle”. The Group has also introduced biomass boilers in some factories. Both approaches have contributed to reducing GHG emissions. The Group will maintain and develop these approaches and work closely with local agricultural producers to keep our business sustainable and to reduce GHG emissions.

Description

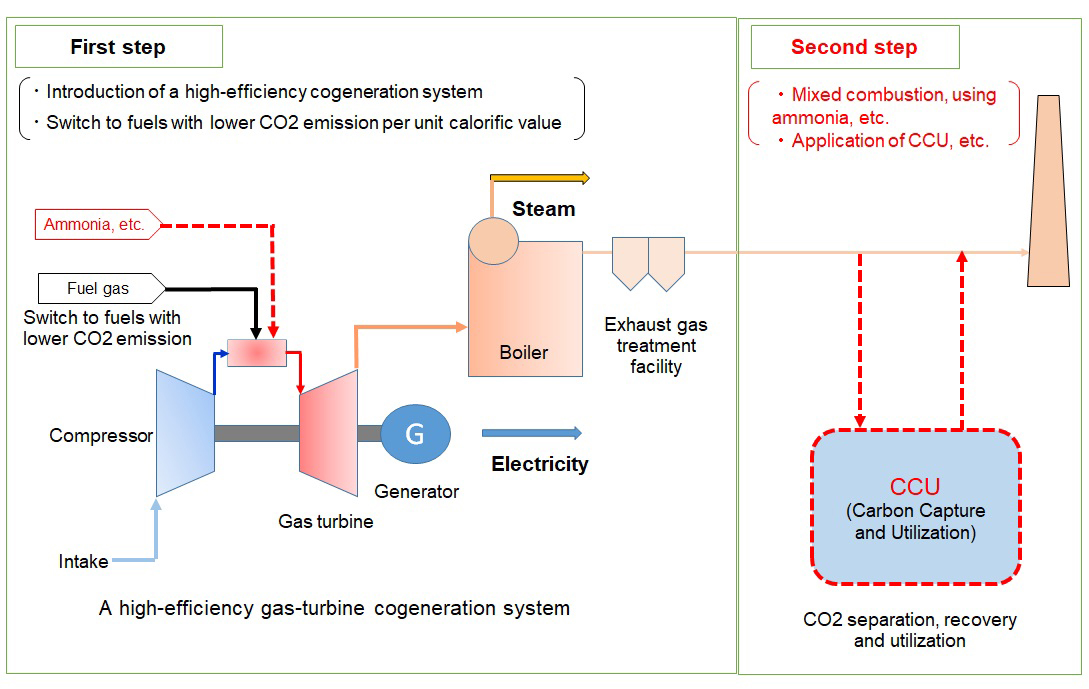

The Ajinomoto Group produces amino acids by fermentation using mainly agricultural crops that are available in each region and uses almost 100% of the nutrient-rich by-product (copro) after extraction of amino acids. The Group has implemented such recycling-based amino acid fermentation processes “Biocycle” into fermentation plants around the world to secure stable raw materials supply and to reduce GHG emissions. This “Biocycle” reduces 1.1 million MT of GHG emission comparing with ordinary organic nitrogen fertilizer. The Group has also introduced biomass boilers in some factories, achieving a renewable energy rate of 24%.

In order to maintain a GHG reduction of 1.1 million MT, it is necessary to operate “Biocycle” stably to maintain GHG reduction. Similarly, for biomass boilers, it is necessary to increase the demand for copro, including incineration ash before expanding biomass boilers in the future.

The Ajinomoto Group also started to sell copro to cabbage plantations, and uses the cabbage produced there as raw material for the gyoza that the Group sells locally. This has ensured not only the stable sales of copro, but the traceability of cabbage and stable procurement of high-quality and good sized-cabbage, bringing benefits to both contract farmers and the Group. The Group is also strengthening cooperation with neighboring farmers to secure copro demand and biomass supply. Through these efforts, we are promoting the resource-recycling based amino acid production and reducing GHG emission.

Partner(s)

Suppliers of raw materials and regional agricultural producers

Supplementary information

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.