Development of CO₂ conversion technology using iron-oxidizing bacteria

Kumagai Gumi Co., Ltd.

Outline

Kumagai Gumi Co.Ltd has developed a technology to produce ethylene, a raw material for chemical products, from CO₂ through a microbial reaction. Ethylene is mainly produced from oil and coal, which emit a large amount of CO₂ during the production process. If ethylene can be produced from CO₂, it is expected to significantly reduce CO₂ emissions and create the industrial field of CO₂ chemistry. We believe that this technology will make a significant contribution to the realization of sustainable carbon-recycling society.

Description

1. Background of Research and Development

The Paris Agreement was adopted at the COP21 held in Paris at the end of 2015. In addition to the 2˚C target for limiting temperature rise, the Paris Agreement also mentions measures to achieve 1.5˚C, such as peaking out greenhouse gas emissions as quickly as possible, and calls for an additional 30 billion tons of global CO₂ reductions by 2050. Around this time, in 2015, the Japanese government made an international commitment to reduce greenhouse gas emissions by 26% in FY2030 compared to FY2013 levels, and at COP24 held in 2018, it was decided to implement the Paris Agreement to achieve the 2˚C target. The Kumagai Gumi has been making good progress toward achieving its 2030 target for reducing CO₂ emissions through fuel-efficient driving and other activities since 2000, but the current reduction effect is nearly 100%, and we are approaching the limit of what we can do with our current efforts.

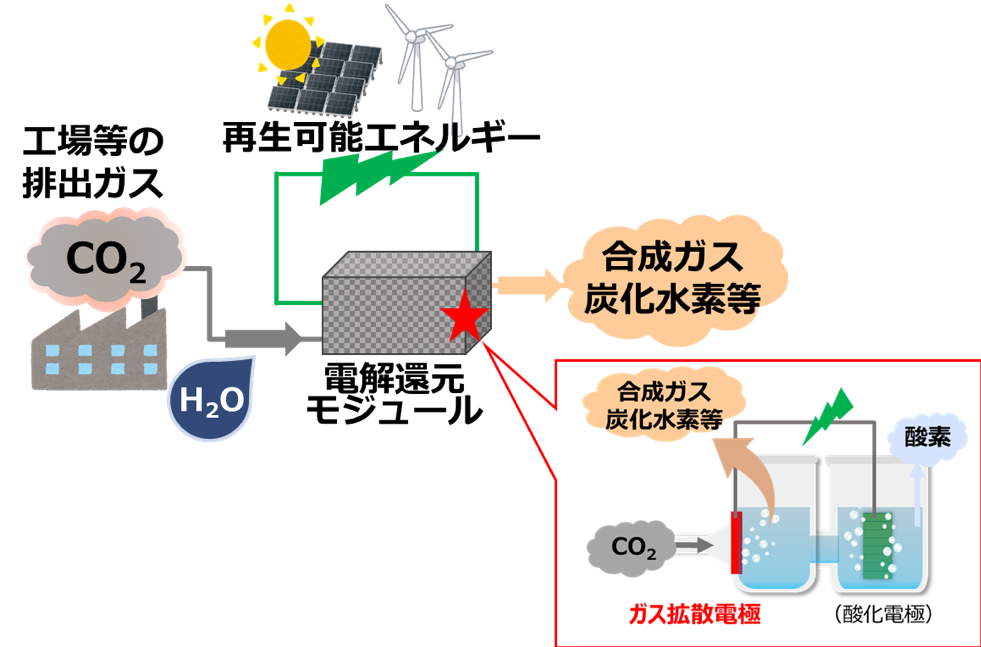

As a countermeasure, the Kumagai Gumi has been working to develop CCU (Carbon Capture and Utilization) technology, which effectively utilizes CO₂ recovered from large-scale sources, with high hopes for the realization of a low-carbon, carbon-recycling society. Although the development of bioprocesses such as artificial photosynthesis and microalgae has been attracting attention, there are currently some problems with the CO₂ treatment capacity and the production efficiency of useful substances, and further improvements are needed to put them to practical use. Therefore, we are developing alternative processes (Figure 1).

2. Outline of Development Technology

With the global trend toward "decarbonization" from the perspective of global warming and the SDGs, we have worked to develop CCU technology based on new bioprocesses, different from artificial photosynthesis and microalgae that could reduce CO₂ emissions and contribute to the realization of carbon cycle society. Specifically, we have developed a technology to produce ethylene, the main raw material for chemical products, from CO₂ using iron-oxidizing bacteria (Figure 1).

By gene modified techniques, ethylene producing enzyme (EFE) intoroduced into an iron-oxidizing bacterium (Acidithiobacillus ferrooxidans,: AF-WT), which grows using CO₂ as a carbon source, we succeeded in constructing a recombinant strain of AF-rEF1 which produces ethylene using CO₂ (Fig. 2). As a result of incubation with high CO₂ concentration, ethylene production was observed in AF-rEF1, while no ethylene production was observed in AF-WT (Fig. 3).

We have also developed and manufactured an electrochemical cultivation system for ethylene production. It is possible to increase the density of iron-oxidizing bacteria by applying electrochemical cultivation technology (patented technology at Central Research Institute of Electric Power Industry) using the current-carrying incubator. In addition, it is thought to be possible to increase the conversion efficiency of CO₂ by providing reduction power through the supply of electrons. Electrochemical culture does not require a large amount of electricity and is expected to use CO₂-free power from renewable energy sources, etc. In addition to using CO₂ as a raw material, it is also expected to reduce CO₂ emissions in the production process. Based on these technologies, we have applied for a patent "Ethylene Production Method and Ethylene Production Equipment" (patent application 2019-154435) as a basic technology for effective CO₂ utilization.

3. Future Prospects

As the productivity of ethylene is still low at this stage, there are still many problems to be solved for its practical application, as well as other existing technologies. Therefore, we are planning to construct a highly efficient ethylene production recombinant strain of iron oxidizing bacteria and to develop an ethylene production system using electrochemical cultivation system.

Partner(s)

Ibaraki University

Shibaura Institute of Technology

Central Research Institute of Electric Power Industry (CRIEPI)

Supplementary information

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

.jpg?id=2&tid=739&imageNumber=1)

.jpg?id=2&tid=739&imageNumber=2)

.jpg?id=2&tid=739&imageNumber=3)

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)