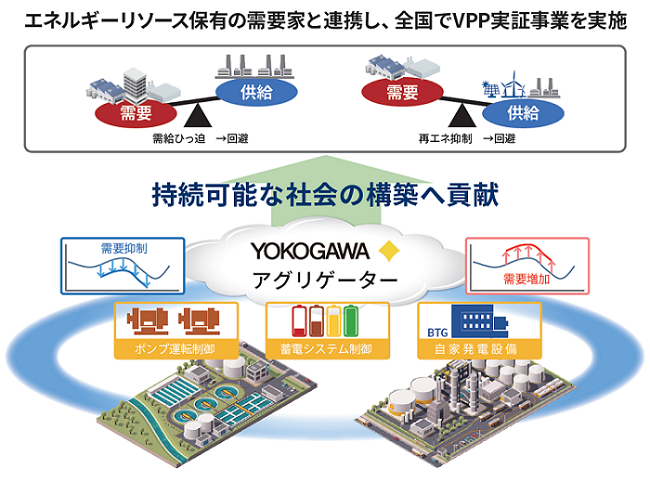

Construction of a virtual power plant that utilizes demand side energy resources

Yokogawa Electric Corporation

Outline

A virtual power plant (VPP) uses advanced energy management technology to remotely control and integrate the management of energy resources of factories and homes, and functions as if these resources were a single power plant.

Interest is growing in the use of such energy systems to expedite the transition from thermal power to renewable energy sources and improve the distribution of power in response to shifts in demand.

The Yokogawa Group participated in a VPP demonstration project carried out by Japan’s Ministry of Economy, Trade and Industry. Through this project, we demonstrated how industrial and social infrastructure such as water pumping stations, power plants, and industrial storage batteries can be used to maintain a balance between power supply and demand.

Moving forward, we will take the resources created by the energy control system powered by the digital technologies built through these demonstrations and use them as flexible adjustment capacity that will grow in importance as renewable energy becomes the main source of power. This aims to lead not only to efficient and effective greening, but also to contribute to the strengthening of Japan's industrial competitiveness.

Description

In recent years, great progress has been achieved in the introduction of solar, wind, and other renewable power sources. However, the power output by renewable energy plants can vary. There is thus an interest in using VPPs to balance the supply of power in periods of peak demand by remotely and integrally controlling the distribution of consumer-side energy resources.

The Yokogawa Group provides measurement, control, and information solutions to companies that operate critical infrastructure. We are very interested in making use of our technologies in VPP solutions that can help our customers better utilize their resources and lead to the wider use of renewable energy.

For these reasons, we have participated in the Ministry of Economy, Trade and Industry’s Demonstration Project for the Construction of a Virtual Power Plant that Utilizes Demand-Side Energy Resources. Through the conduct of surveys and other studies that focus on the in-house generation of power and the use of industrial storage batteries in VPPs by companies in the water supply and manufacturing industries, we are working to realize a low-carbon society and create new value.

In the industrial sector, we are working with Idemitsu Kosan Co., Ltd. to make use of the reserve capacity of a large-scale boiler turbine generator (BTG) at Seibu Oil’s (an Idemitsu Kosan subsidiary) Yamaguchi Refinery to compensate for fluctuations in the power drawn from renewable power sources. Regarding storage batteries, at oil depots and lubricant plants in Niigata City and Kobe City, batteries with capacities of several hundred kWh are used to provide agile load-following capability for rapid shifts in demand that cannot be met by power generated in-house. We are verifying the use of a mechanism that utilizes “multi-loose” peak load shifting to improve the balance between power supply and demand.

Furthermore, we are working with water utilities that wish to make more effective use of their facilities and conserve power by verifying a mechanism that adjusts the on/off timing of water pumps that are distributed over a wide area.

Based on this verification, with VPP we will further promote the consumption of power in the industrial field when there is surplus power generation, the application of storage batteries to the industrial solar self-consumption model, and overall optimization that combines the different characteristics of industrial and social infrastructure resources. These efforts will become more important due to the promotion of renewable energy adoption and will contribute to the growth and expansion of distributed energy resources. Through such activities, the Yokogawa Group is working with its customers to promote the aims of the Challenge Zero initiative.

Partner(s)

Idemitsu Kosan Co., Ltd.

Seibu Oil Co., Ltd.

Yokogawa Solution Service Corporation

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

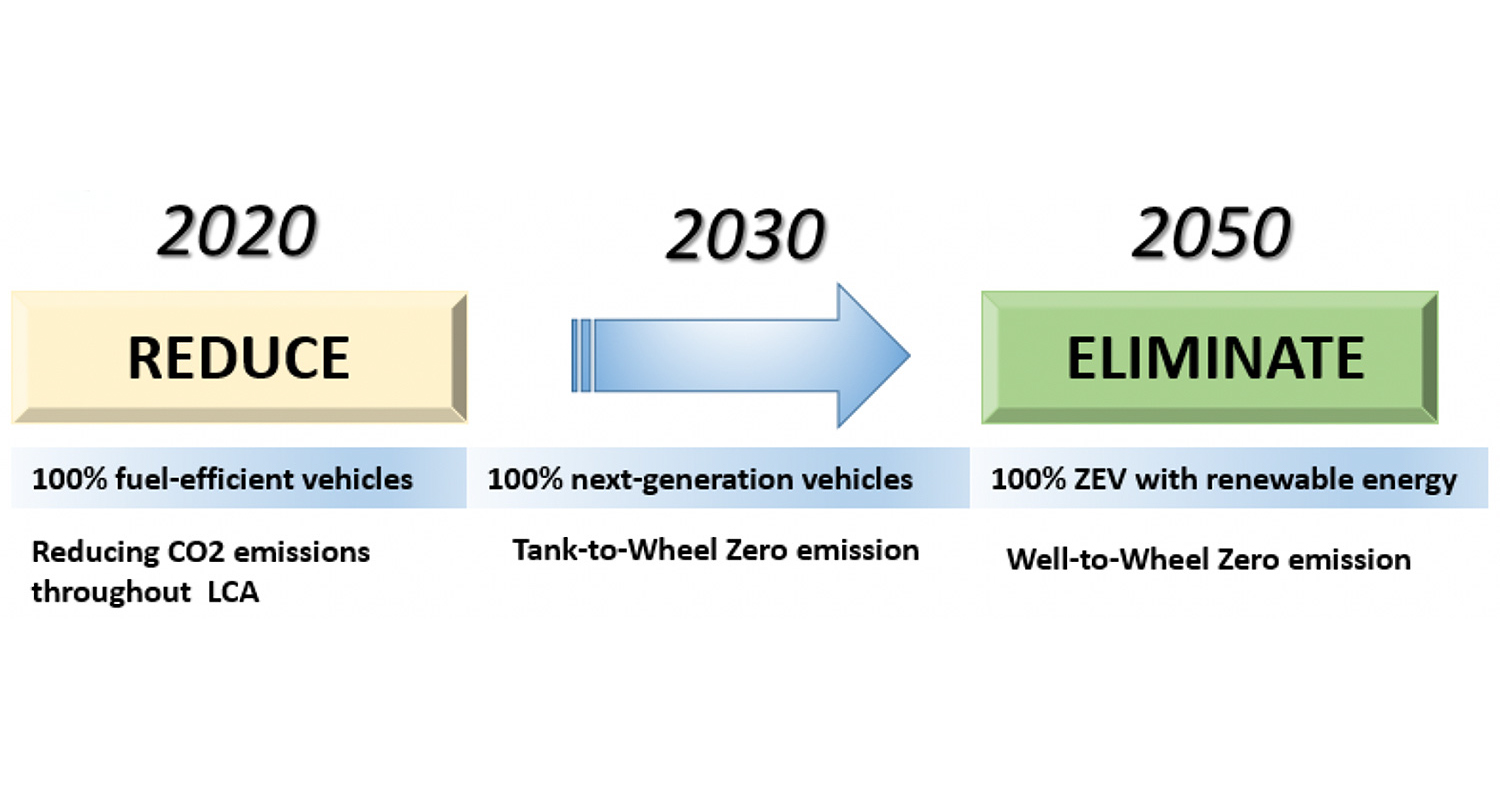

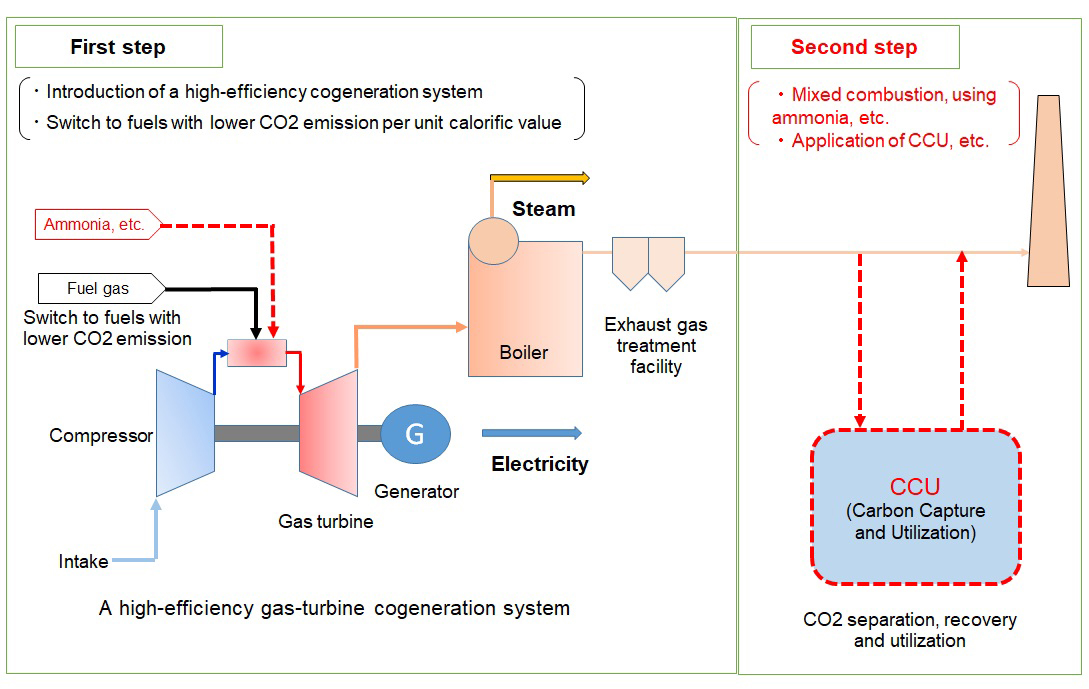

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.