Reduction of CO2 emissions due to spread high efficiency amorphous transformers

Hitachi Metals,Ltd.

Outline

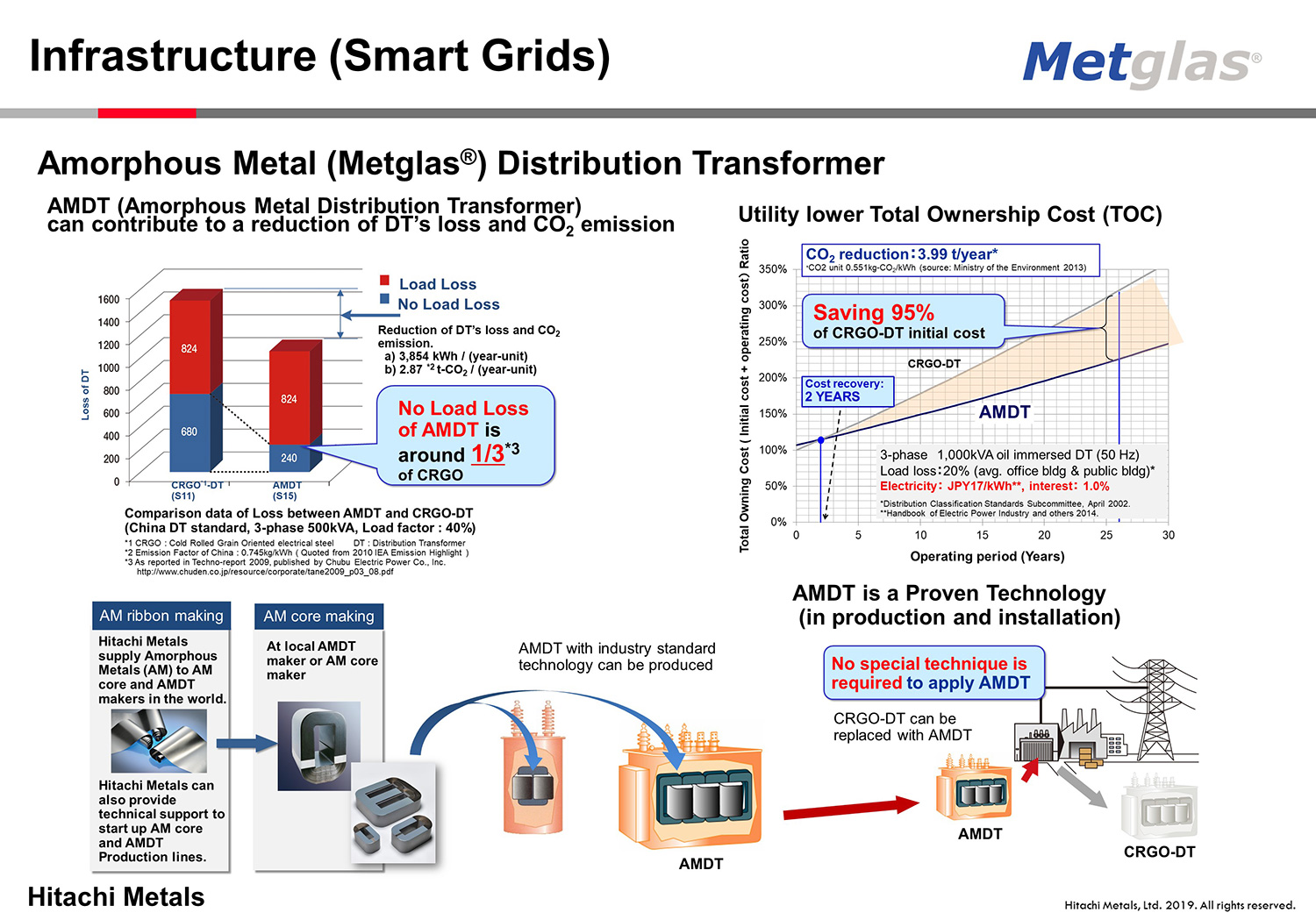

Transformers that use Fe-based amorphous alloy/Amorphous Transformers have a small no-load loss (iron loss) of about one-third compared to those that use silicon steel/conventional Transformers, and can greatly contribute to energy savings and CO2 emissions reduction.

Even though the amorphous transformer has been in the market for more than 30years, the worldwide penetration rate of amorphous transformer is only 14% (our estimates), because manufacturing requires special processing and known-how, the initial cost rises and the standards or regulations on energy saving transformers is not sufficient.

We contribute to a sustainable low carbon society, by solving these issues and spreading the amorphous transformer to the world.

Description

[Goal]

- 30% global penetration of Amorphous Transformers

[Challenges]

- Lower initial cost for introducing amorphous transformers

- Conversion of evaluation indicators ( to use the Total Owning Cost Indicator )

[Actions]

- Participate in CEFIA workshops by sharing case studies of Amorphous Transformers in other countries and Global Efficiency Trends

- Lobby merit of Amorphous Transformers to the governments and the power distribution companies, which especially highly depend on coal-fired power generation, by quantifying the benefits of the Amorphous Transformers vs conventional Transformes based on enhanced efficiency and reduction of GHG.

- Co-work and support with local manufactures by Japanese manufacturing way called “MONOZUKURI” technology and known-how to make Amorphous Transformers, and contribute to expand electrification ratio and further job creation.

- Further contribution of saving energy with new amorphous metals named “MaDC-A”, which can reduce 25% iron loss compared to conventional amorphous metals.

[Effect] (our estimates)

- Reduction of CO2 emissions : * 4,665,500t CO2/year ( equivalent to 32 million kW coal-fired power plants)

* CO2 reduction factor : 0.4kg-CO2kW/h

Supplementary information

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.