Power to Chemicals ~Recycling of carbon dioxide via electrolysis powered by renewable energy~

TOSHIBA CORPORATION

Outline

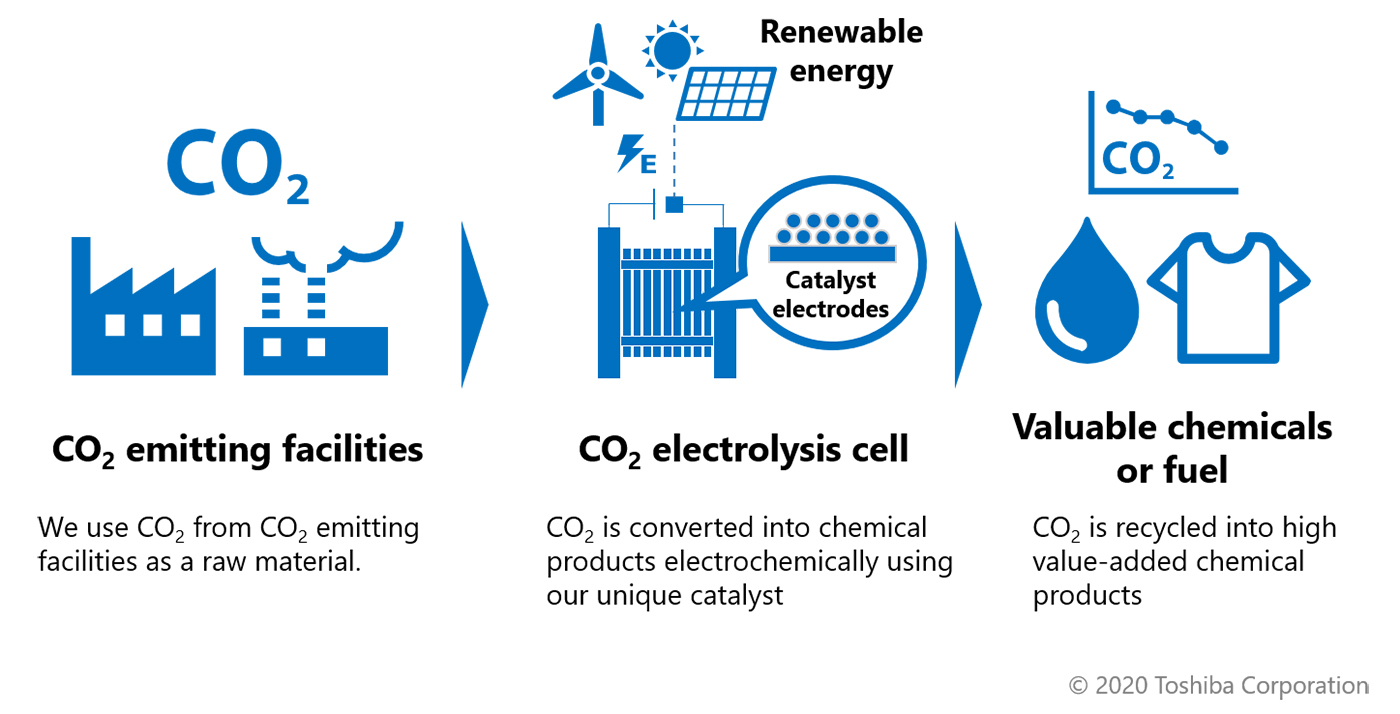

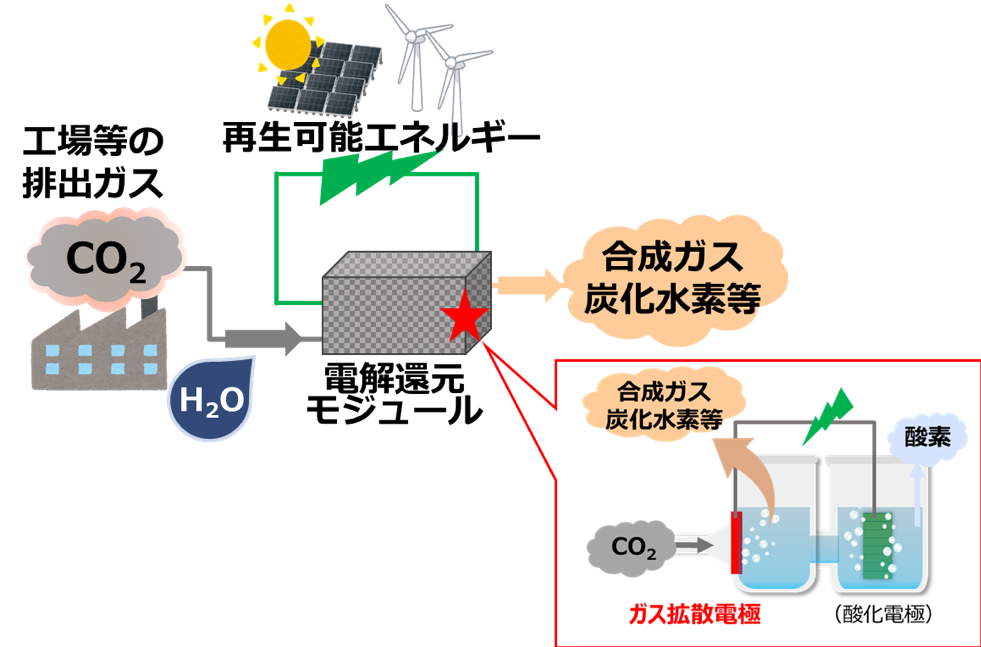

We are promoting the development of Power to Chemicals technology to make effective use of CO2 and to disseminate renewable energy. This technology can recycle CO2 gas via electrolytic reduction powered by renewable energy or its surplus power.

Although artificial photosynthesis can be used to convert CO2 into carbon monoxide, which is a raw material for jet fuel and plastics, traditional technology suffers limitations in terms of costs and installation locations due to its slow conversion speed. Therefore, we have studied the catalysts and electrode structures for CO2 electrolytic reduction and developed our unique catalyst electrode with the world’s top-level conversion speed. Using this technology as a foundation, we made an electrolysis cell stack capable of electrolytically reducing CO2 to carbon monoxide at the ton-per-year level and verified its operation with a CO2 recycling system. Based on these results, we will continue to develop a MW-class CO2 recycling system which can be installed at various CO2 emitting facilities, in anticipation of a carbon neutral society.

Description

We are developing a CO2 recycling system (Power to Chemicals) to electrolytically reduce CO2 into carbon monoxide, a raw material for jet fuel and plastics. We have been developing a catalyst electrode capable of increasing the CO2 processing volume for the establishment of a high-throughput technology, which is key to realize this Power to Chemicals system. By reacting the CO2 gas with water instead of dissolving the CO2 in water, we suppressed the current density (conversion speed) decrease. Furthermore, the catalyst layer has a unique structure having macro-sized pores, which act as CO2 flow channels, as well as nanometer-sized pores, allowing higher concentrations of CO2 to be efficiently delivered to the catalyst surface. As a result, we have successfully converted CO2 at a world-record current density of 645 mA/cm2. We have also made a CO2 recycling demonstration system capable of processing CO2 at a maximum 1 ton per year based on this technology. We were able to greatly increase the CO2 processing volume by applying high current density operation, electrode area expansion, and electrolytic cell stacking to the CO2 electrolysis cell, which is the core technology of this system. We have also verified the extended operation of a CO2 electrolysis cell stack. Furthermore, we have studied the effects of power fluctuations using a power source emulating renewable energy in order to develop a CO2 recycling system applicable to a real-world environment, as well as the effects of impurities in the CO2 gas expected from a thermal power plant using a simulated collected CO2 gas. Based on these results, we aim to socially implement and spread the use of a MW-class CO2 recycling system applicable to facilities emitting large amounts of CO2 such as waste incineration plants.

Partner(s)

A portion of this technology was demonstrated within a project commissioned by the Ministry of the Environment (“Project for Establishing a Model of a Carbon-circulating Society Based on CO2 Recycling: Verification of a Community-compatible CO2 Recycling Model Based on Artificial Photosynthesis Technologies at Large CO2-emitting Facilities, 2022 Fiscal Year”).

Supplementary information

Promotion video of Power to Chemicals

https://www.global.toshiba/jp/technology/corporate/rdc/rd/video/nano-p05.html

Press release (2019.03)

https://www.global.toshiba/jp/technology/corporate/rdc/rd/topics/19/1903-02.html

Press release (2021.03)

https://www.global.toshiba/jp/technology/corporate/rdc/rd/topics/21/2103-02.html

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)