High efficiency technology for Fuel Cells

Tokyo Gas Co., Ltd.

Outline

The power generation efficiency of solid oxide fuel cells (SOFCs) in practical use exceeds the average that of the thermal power plants, but it is desired to achieve further increases in efficiency to realize a carbon free society in the future. The Group is working on improving the efficiency of SOFCs using two approaches. The first approach is to put the technology for improving the efficiency of SOFC into practical application by combining two-stage SOFC stack technology and a fuel regeneration technology so as to use more of the fuel input for power generation. This approach is in the stage of verification tests of a power generation system in cooperation with system manufacturers. The second approach is to develop a proton-conductive SOFC that uses a material called a proton conductor for the electrolyte, which is different from the conventional SOFC, then to research and develop a further high efficiency technology by combining the new SOFC with the first technology.

Description

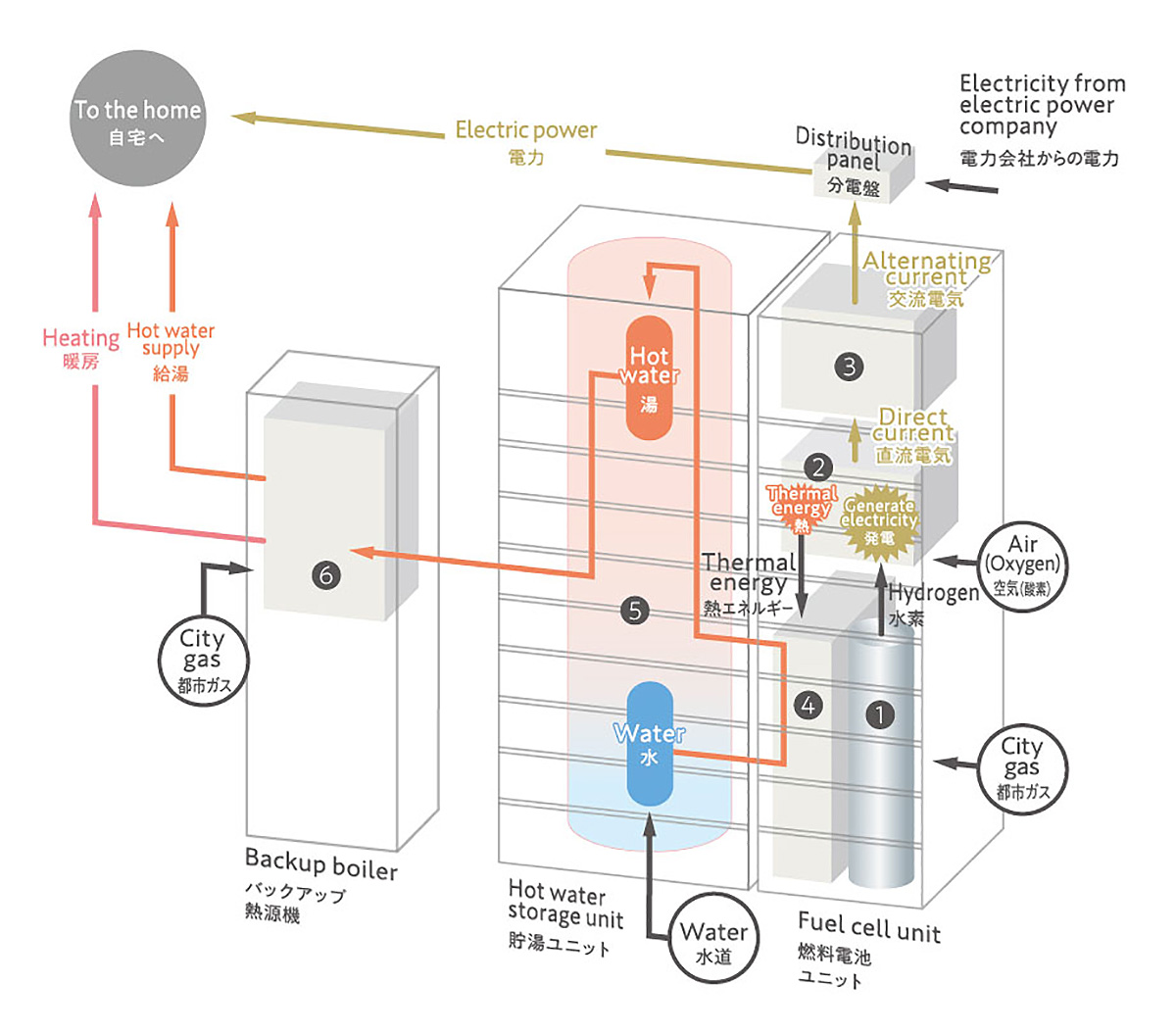

The solid oxide fuel cells (SOFCs), which are currently in practical use for household use, business use and industrial use, utilize city gas whose main component is environment-friendly natural gas as a fuel, and 50 to 60% LHV of power generation efficiency is achieved. This power generation efficiency is higher than the average thermal efficiency of thermal power plants, but further improvement in efficiency is desired for realizing a carbon free society in the future. At present, the Group is working on improving the efficiency of SOFC in two main approaches in cooperation with other companies, research institutes and universities.

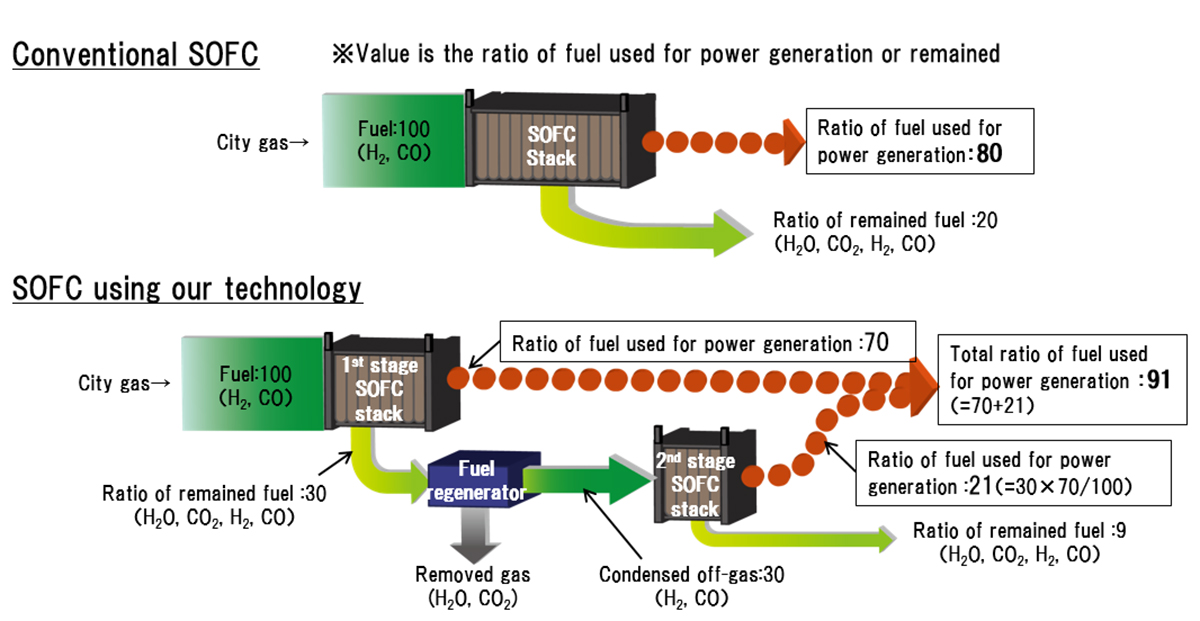

The first approach is the practical realization of the technology for improving the efficiency of SOFC by combining a two-stage SOFC stack technology and a fuel regeneration technology so as to use more of the fuel used for power generation. In this system, the fuel supply lines of the two stacks are arranged in series, and a fuel regeneration process is provided between the two stacks. After the fuel off-gas was used for power generation in the first stack, CO2 and H2O that do not contribute to power generation in fuel off-gas are separated and removed in the fuel regeneration process. Consequently, the concentrations of the unreacted H2 and CO contained in fuel off-gas increase, and it makes it possible to effectively reuse off-gas in the second stack. In this way, while 70 to 80% of the input fuel is used for power generation in the conventional SOFC system, more than 90% of the fuel can be used in this system. The principle of this systemization technology was investigated in FY2017 using a 5kW-class output scale and the world's first power generation efficiency of 65% LHV was demonstrated using only the main components. At present, we are developing a system and conducting the verification tests in conjunction with MIURA CO, LTD with the aim of practical realization of this system. We study and verify the power generation performance, durability and reliability of the system, and pursue the early commercial achievements of the system by using the knowledge obtained in this verification stage and by resolving issues.

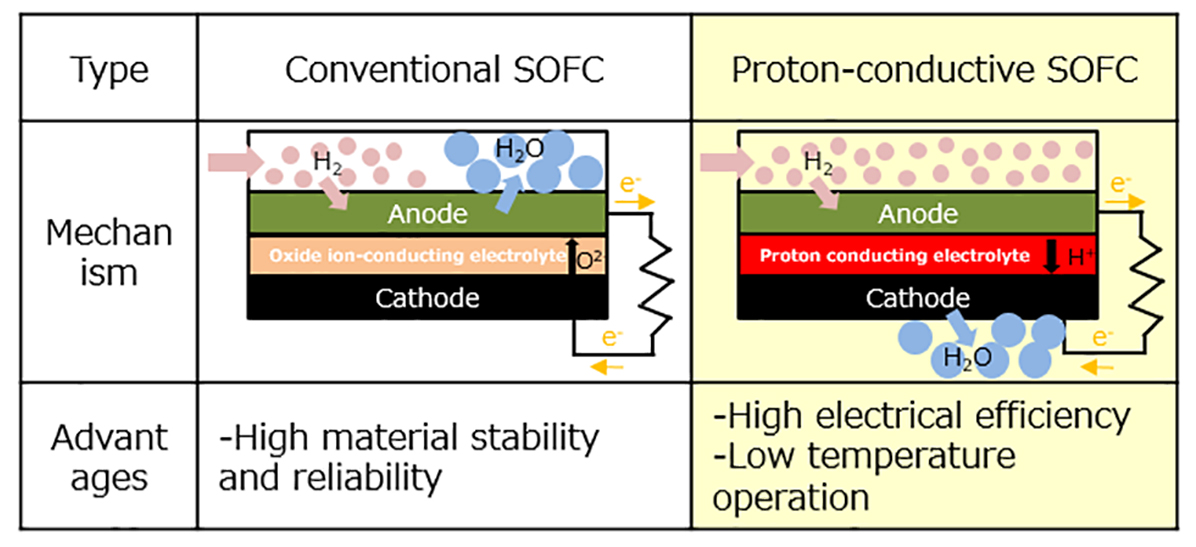

The second approach is the research and development of high efficiency technology that combines proton-conductive SOFC and the first systemization technology. The current SOFC generates electricity by conducting oxide ions (O2-) through the electrolyte, while the proton-conductive SOFC generates electricity by conducting protons (hydrogen ions, H+) through the electrolyte. Unlike the conventional SOFC using an oxide ion conductor as an electrolyte, the proton-conductive SOFC is expected to have high power generation efficiency because water generated by power generation does not dilute the fuel. In collaboration with Kyushu University, our group has confirmed through simulations that power generation efficiency over 80% can be achieved by combining the proton-conductive SOFC with the system technology for high efficiency shown in the first approach. Currently, we are working on research and development of oxides with high proton conductivity and material stability in order to realize a proton-conductive SOFC stack that meets the system requirements.

Furthermore, in the future, we plan to work on the practical application of the technology that combines proton-conductive SOFC with the first systemization technology for higher efficiency.

Partner(s)

・ MIURA Co, ltd (we are developing a system and conducting the verification tests in conjunction with MIURA CO, LTD with the aim of practical realization of this system.)

・ Kyushu University (In collaboration with Kyushu University, we have confirmed through simulations that power generation efficiency over 80% can be achieved by combining the proton-conductive SOFC with the system technology for high efficiency shown in the first approach)

Supplementary information

More detailed information about the project can be found at the following website.

https://www.tokyo-gas.co.jp/Press/20170523-01.html

https://www.tokyo-gas.co.jp/Press/20150729-01.html

https://www.tokyo-gas.co.jp/Press/20200304-02.html

Other Innovation Challenges

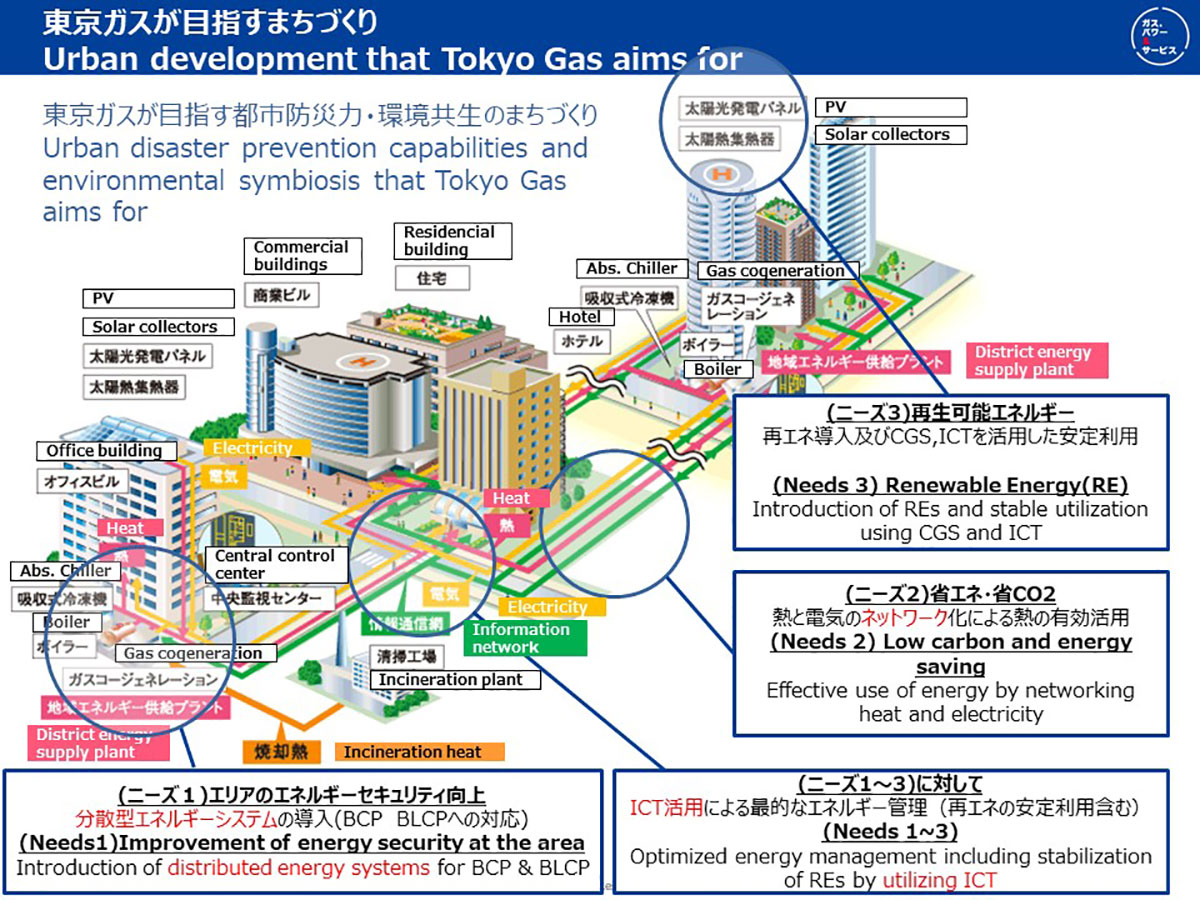

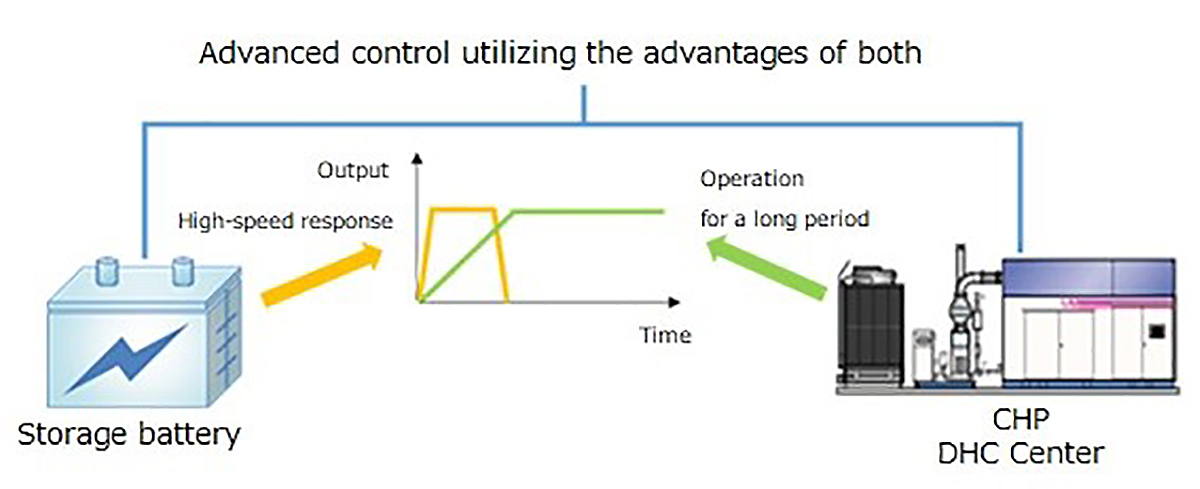

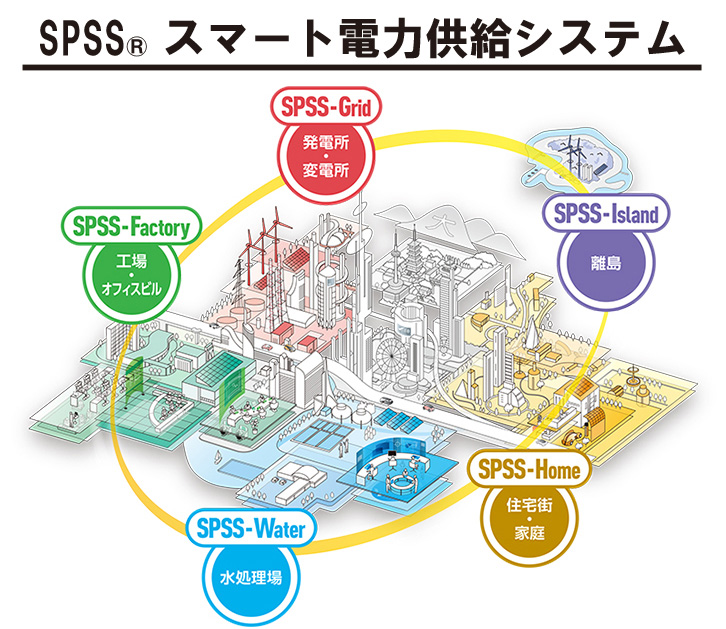

Utilization of distributed energy resources (The Virtual Power Plant)

Tokyo Gas Co., Ltd.

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

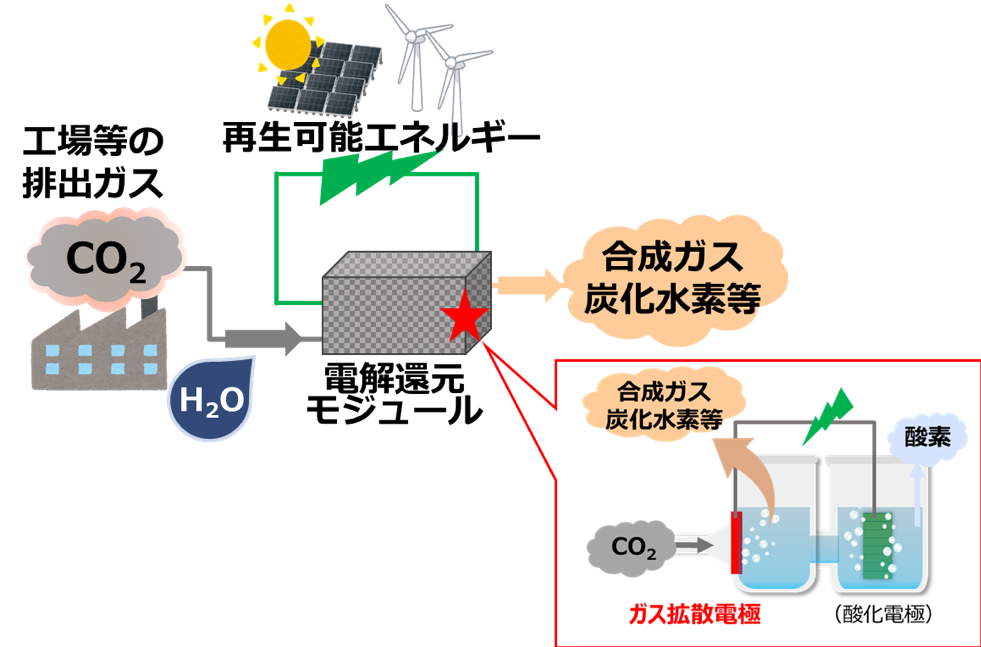

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)