Technical development of intermediate materials for aircraft

TEIJIN LIMITED

Outline

The aircraft market is said to almost double in the next 20 years.

Among them, it is expected that the delivery of thin body machines (single aisle machines) will account for 75% of the total, and there is a strong demand for energy saving and cost reduction of these single aisle machines *1, *2.

In order to achieve these targets, low cost, intermediate materials for aircraft that contribute to high cycle process are required. By accelerating and adopting these technological developments, Teijin has expanded the application range of lightweight Carbon Fibers Composites materials (50%), we aim to reduce the life cycle CO2 emissions of aircraft by 7%. *3

Description

Among aircraft materials, Teijin aims to develop and put into practical use the following intermediate materials.

① Tenax® Dry Reinforcements Non-Crimp Fabrics (DRNF)*4

Tenax® Dry Reinforcements are specially designed for the aerospace industry, offering high performance, flexibility and the ability to create complex geometries. By combining textile technology and resin injection process, we can achieve a high production rate, integrated order, and complex shape, and aim to put the aircraft industry to practical use in the future.

② Thermoplastic prepreg material*5

Tenax® TPUD is a tape-shaped prepreg (a Carbon Fibers sheet impregnated with resin) that uses a thermoplastic resin as a foundation material, and has excellent heat resistance, impact resistance, fatigue resistance, etc. can greatly shorten the forming time, which greatly contributes to the improvement of cost efficiency in the manufacturing process. We anticipate full-scale adoption by next-generation aircraft that aircraft manufacturers are planning to launch, and aim to start supplying "Tenax® TPUD" to aircraft component manufacturers within 2021.

③ Thermosetting prepreg material*6

We are developing a high-performance high-speed curing prepreg (carbon fibers sheet impregnated with resin) with improved heat resistance and impact resistance based on a high-speed curing type prepreg developed for automobiles. Started material drafts for aircraft component manufacturers.

By using these intermediate materials in the right places, it is possible to reduce the cost of aircraft parts, accelerate the application of lightweight Carbon Fibers Reinforced Composites materials, and contribute to improving the fuel efficiency of aircraft and reducing CO2.

Other Innovation Challenges

Development of Carbon Fibers for pressure vessel supporting the realization of hydrogen society

TEIJIN LIMITED

Low Speed EV (LS-EV) development toward “Well to Wheel Zero Emission Mobility” and Challenge for improving a social services (QOL) by utilizing its platform

TEIJIN LIMITED

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

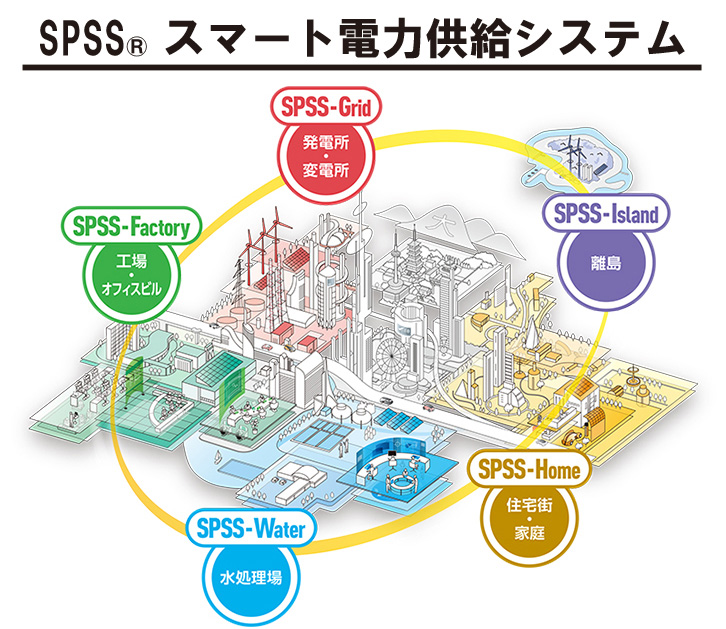

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

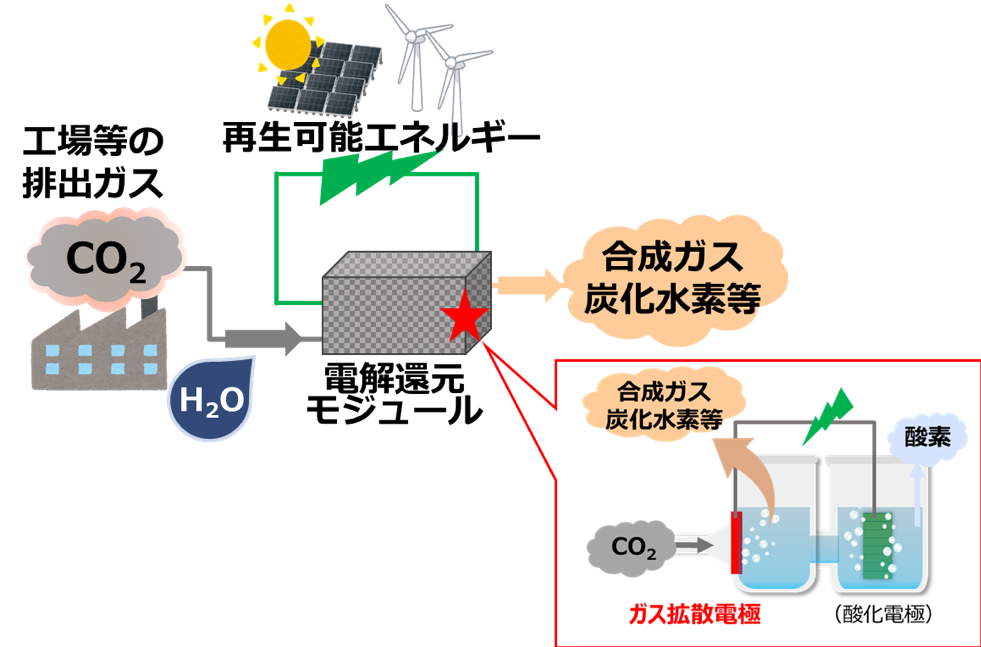

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)