Innovative optimization of petroleum refining process through “Petroleomics” technology

Petroleum Association of Japan

Outline

"Petroleomics" is the fundamental technology for realizing the innovative optimization of petroleum refining process, through analyzing tens thousands to millions of molecular structure and composition which are ingredients of crude oil and residual oil.

Until now, the development of refining process about residual oil and the setting of operating conditions about refining unit, etc. they have been advanced based on limited information such as general properties of feedstock (boiling point, etc.) and past experience.

Detailed information provided through the development of "Petroleomics" technology, are enabling an innovative "molecular level" approach to the development and the operating improvement on refining processes.

As a result, it becomes possible to produce more high value-added products from crude oil and to save energy in refinery facilities, etc.

"Petroleomics" technology is an innovative "transition technology" that is necessary to achieve stable and efficient supply of petroleum products and global warming countermeasure simultaneously.

Description

1. Details of "Petroleomics" technology

Petroleomics technology is an innovative fundamental technology for further optimizing and improving the efficiency of the petroleum refining process, and consists of three main technologies,

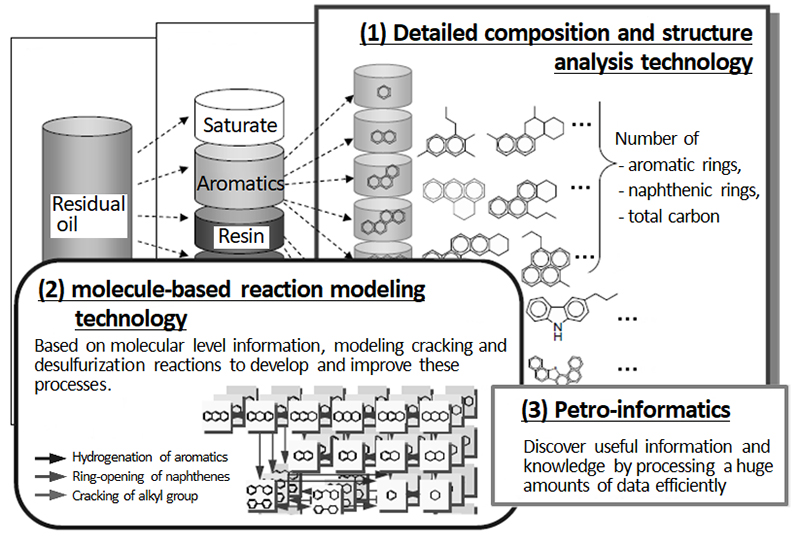

(1) “(detailed) composition and structure analysis technology” for analyzing and elucidating the detailed structure and composition of petroleum molecules,

(2) “molecule-based reaction modeling technology” for analyzing and modeling the reactivity of petroleum molecules,

(3) "Petro-informatics" for handling enormous information obtained by detailed composition analysis.

Crude oil and residual oil contain more than tens of thousands of components, especially residual oil has extremely complicated molecular structure and composition, so it was difficult to grasp its detailed structure and composition.

By the development of key technologies simultaneously, such as

(1) the utilization of ultra-high performance analyzer (Fourier transform ion cyclotron resonance mass spectrometry (FT-ICR-MS)),

(2) analysis technology corresponding to FT-ICR-MS,

(3) information processing technology that systematically deals with the obtained information,

"Petroleomics" technology is allow residual oil to be handled at the “molecular level”, will bring a new and innovative approach to the technology development of petroleum refining processes.

We have started technology development since FY2011.

2. Application to petroleum refining process

"Petroleomics" technology is an “innovative fundamental technology” used for the development of petroleum refining processes and the improvement of operations, etc., so it is also important to approach the development of petroleum refining processes using "petroleomics" technology.

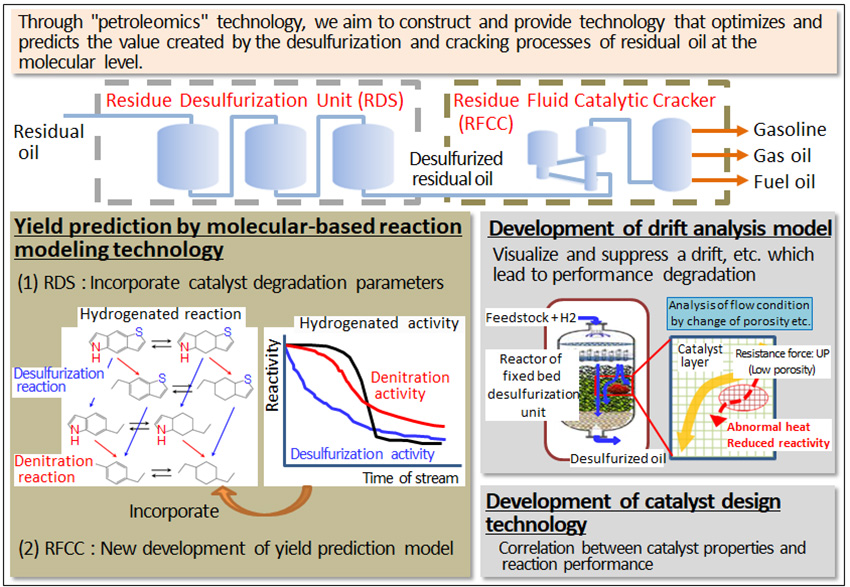

Up to now, in parallel with the development of "petroleomics" technology, we have been challenging to apply this technology to the development of refining process, (1) development of technology for more efficient desulfurization and cracking about residual oil, (2) Technology development for increasing the throughput of ultra-heavy crude oil (it is a higher proportion of heavy oil than conventional crude oil, and it is difficult to refine with conventional process), etc..

In petroleum refining, a large amount of energy is required in the process of (a) reducing the sulfur content (desulfurization) of heavy oil for the purpose of protecting the air environment, and (b) cracking heavy oil into gasoline (the demand of residual oil is decrease more than other products).

By tackling technological development utilizing "petroleomics" for these processes, we will continue to pursue more effective use of precious petroleum resources, and more reduction of load to global environment with production and use of petroleum products.

Partner(s)

This technology is being developed in cooperation with the Japan Petroleum Energy Center (JPEC) and petroleum companies, etc. with the support of the Ministry of Economy, Trade and Industry (METI).

Supplementary information

Japan Petroleum Energy Center (JPEC)

http://www.pecj.or.jp/english/index_e.html

Other Innovation Challenges

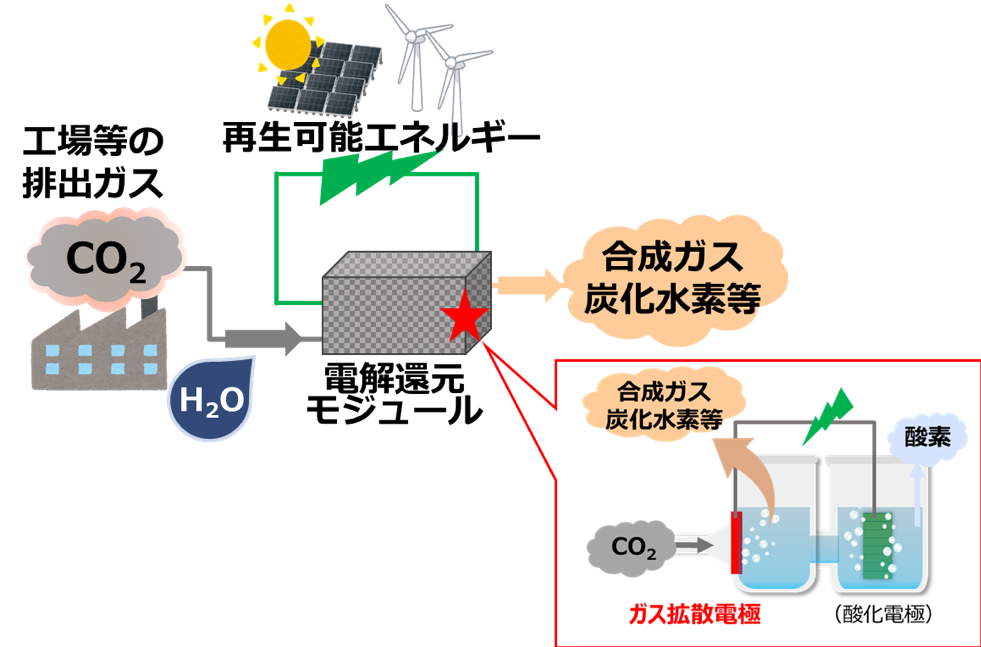

Development and social implementation of carbon neutral fuels “e-fuel” produced from CO2

Petroleum Association of Japan

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

.png?id=2&tid=831&imageNumber=1)

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)