Social development of inkjet technology

SEIKO EPSON CORPORATION

Outline

We have established ink ejection technology that does not use heat with our unique micro piezo technology and used this technology to form a common technical base for all Epson inkjet printers, including those for homes and offices. Using this technology, we promote inkjet innovations that provide the necessary functions for a society with minimum environmental impact. We aim to realize a sustainable society, and circular economy through industrial structural innovation. In FY2018, the company opened a new plant that triples the production capacity of print chips, a key element of inkjet heads. In addition to mass-production, the new plant includes development facilities for low-environmental-impact products for commercial and industrial printing. These facilities began operation in early 2020, building the foundation for innovating for a wide variety of industrial structures.

Description

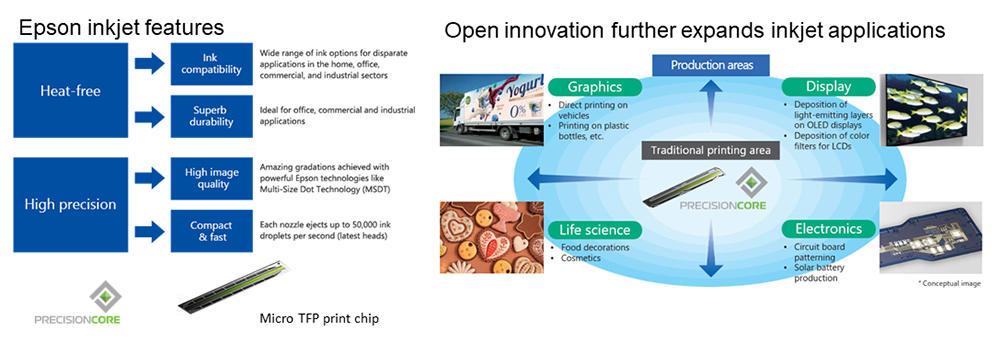

We have developed unique micro piezo technology and are working to sharpen our technology for discharging ink without using heat. Printers using this Heat-Free Technology have significantly lower power consumption than laser printers, which operate by thermally fixing toner particles.

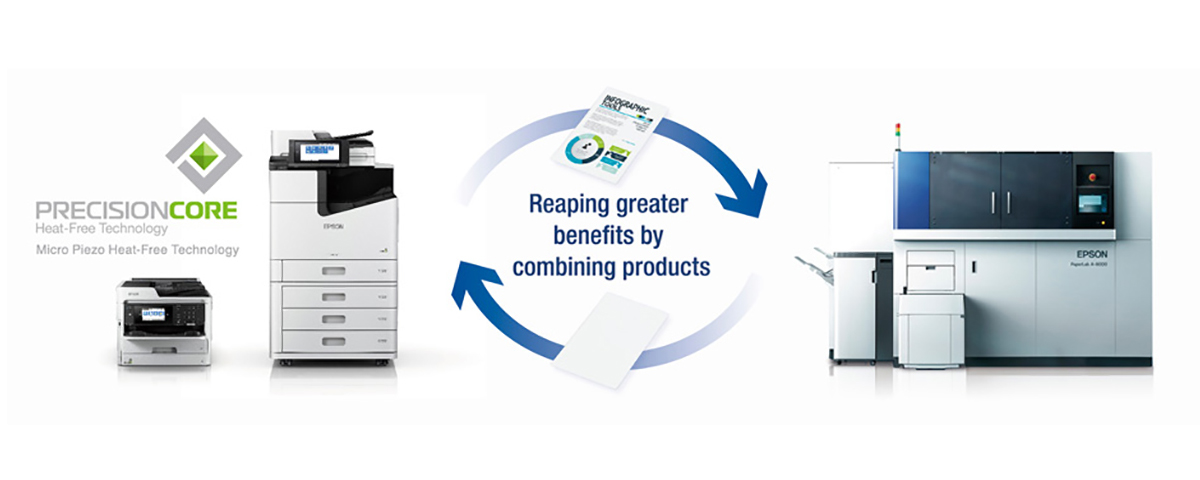

Our micro piezo technology, honed over many years of intensive research, has evolved dramatically; the current commercial iteration of this technology, dubbed PrecisionCore print head, combines micro-piezo with high-precision MEMS technology. In addition, the company has incorporated this print head in an inkjet device for R&D, so that researchers in a variety of fields can develop new applications of inkjet technology.

The company’s Fujimi plant opened a collaborative research facility, the Inkjet Innovation Lab, in order to accelerate the development of environmentally conscious industrial solutions in accordance with our basic policy of "maximizing use of assets and accelerating growth through collaboration and open innovation".

In addition, incorporation a capital tie-up with Elephantec Co., Ltd., which manufactures and sells flexible printed circuit boards, has is an innovative production that uses less than 1/10 energy, water and waste compared to conventional processes (according to Elephantec Co.,Ltd.). Began providing flexible substrates in the process.

In order to become a partner to innovate customers' production processes with low power consumption inkjet technology, we are promoting the external sales of PrecisionCore technology print heads and challenging the formation of a sustainable society.

Partner(s)

Capital tie-up with Elephantech Co., Ltd.

Supplementary information

Micro piezo technology

https://global.epson.com/innovation/core_technology/inkjet/micro_piezo.html

Inkjet Innovation Lab Fujimi

https://global.epson.com/newsroom/2019/news_20190826.html

Providing print heads for external sales

https://global.epson.com/IR/library/pdf/integrated_report/epson_ir2019_11_e.pdf

Other Innovation Challenges

Micro devices that prevent loss of social infrastructure

SEIKO EPSON CORPORATION

Robotics technology that realizes thorough power saving

SEIKO EPSON CORPORATION

Similar Innovation Challenges

Achieving net zero carbon emissions from paint finishing processes

Taikisha Ltd.

Activities for reducing GHG of business operations in Nissin Electric Group

Nissin Electric Co., Ltd.

-1人工光合成技術.jpg?id=2&tid=759&imageNumber=1)