Development and production of parts and equipment that contribute to electrification of automobiles

JTEKT CORPORATION

Outline

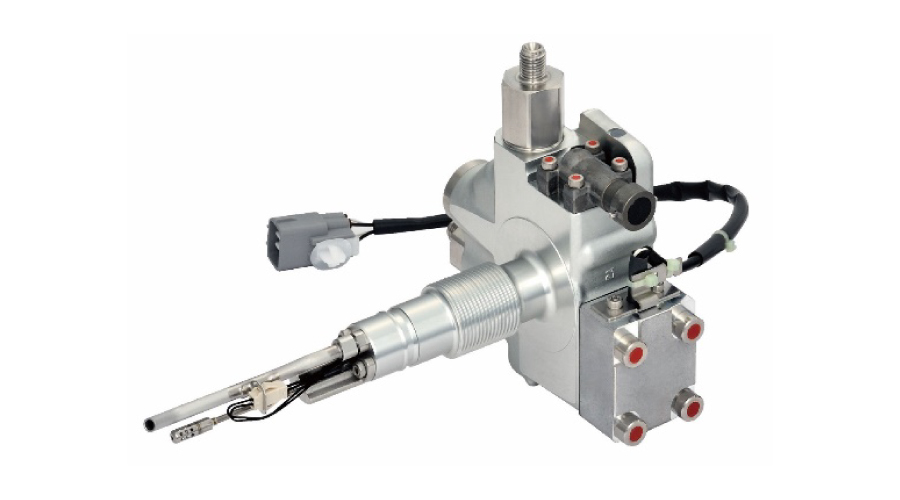

JTEKT has developed and produced high-pressure hydrogen supply valve for fuel cell vehicles, which are ultimate eco-cars that run on hydrogen and do not emit CO2 or air pollutants.

As a result of expansion of fuel regulations and spread and expansion of

automatic operation, there is a need to expand the application range of electric power steering (EPS), which greatly contributes to energy saving and automatic driving.

Our lithium-ion capacitor has superior characteristics at both low and high temperatures, and enabled expanding range of EPS mounting for large vehicles.

It has contributed to energy saving in industrial fields by high-efficiency power regeneration and instantaneous power support.

As needs of batteries for electric vehicles increase, we produce battery manufacturing equipment as well.

High-precision grinding machine that grinds rolls required in battery manufacturing facilities has also contributed to the electrification of automobiles.

Description

Our high-pressure hydrogen supply valve is mounted on a hydrogen tank filled with high pressure of 700 atmospheres, and has realized high sealing performance by utilizing the high pressure oil control technology cultivated over the years with hydraulic power steering to seal and supply hydrogen.

JTEKT plans to produce approximately 30,000 high-pressure hydrogen supply valves by 2020.

On the other hand, pressure reducing valve decompresses the high pressure hydrogen supplied in the lower stack to the usable level, and supports the high pressure hydrogen system.

We will aim to contribute to the spread of the coming hydrogen society by developing new components other than valves and pressure reducing valves.

JTEKT plans to produce one million lithium-ion capacitor cells by 2020.

In the future, we plan to sell modules in which capacitor cells are serialized and systems combining charge-discharge controllers.

We propose to use the lithium-ion capacitor not only as an auxiliary power supply for EPS, but also in various fields such as automotive fields including backup power supplies for automatic driving, machine tools, construction machinery, railways, power generation equipment, transportation infrastructure, etc.

The lithium-ion capacitor can contribute to improving energy efficiency and environmental properties of all industries in various applications such as auxiliary power supply, standby power supply, stabilizing of power generator functions, power supply regeneration, main power supply, etc.

As for battery manufacturing facilities, we mainly manufacture facilities for electrode processes (kneading, coating, and press slitting) that greatly affect the battery performance of lithium-ion batteries.

In recent years, Machine Tools Development Dept. has been put in charge of our lithium-ion capacitor electrode processing equipment.

In addition, the department has also developed a high-precision grinding machine for high-performance roll processing that is indispensable for electrode processing equipment, and will respond to the needs of higher precision, higher quality and longer life of rolls.

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.