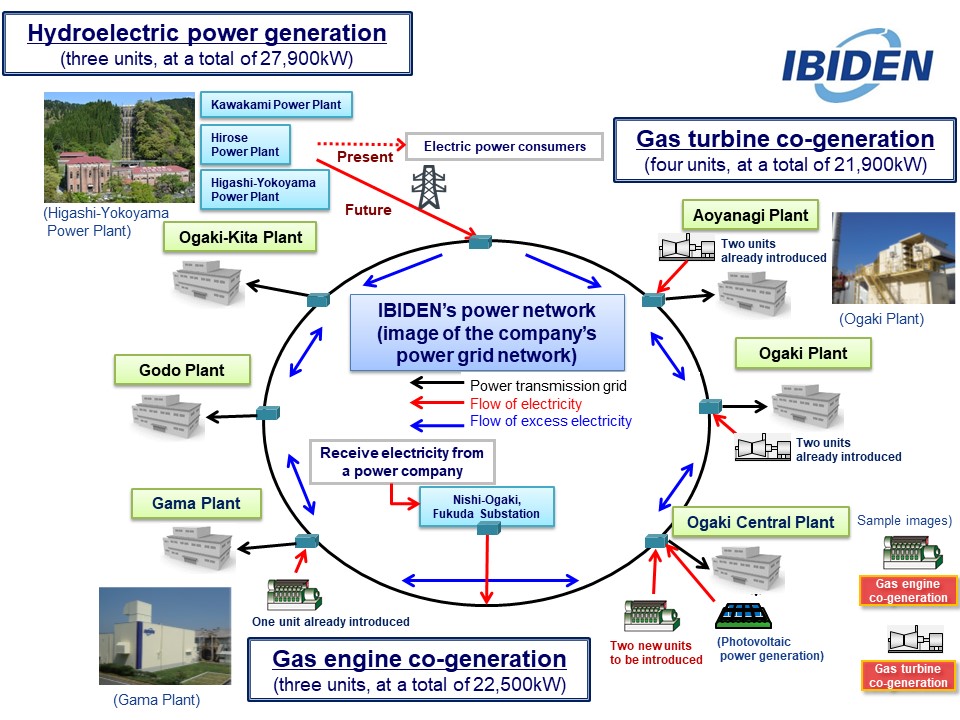

Introduction of high-efficiency co-generation and establishment of our in-house smart grid

IBIDEN CO., LTD.

Outline

We have expanded from our original business of hydroelectric power generation in 1912 to our current business of ceramic and electronic products by changing our technologies that we have accumulated since our company’s founding. And now, we plan to take up the challenge of improving the electric power infrastructure toward the realization of a low carbon society while promoting a production increase of our next-generation IC package substrate for the development of an information society.

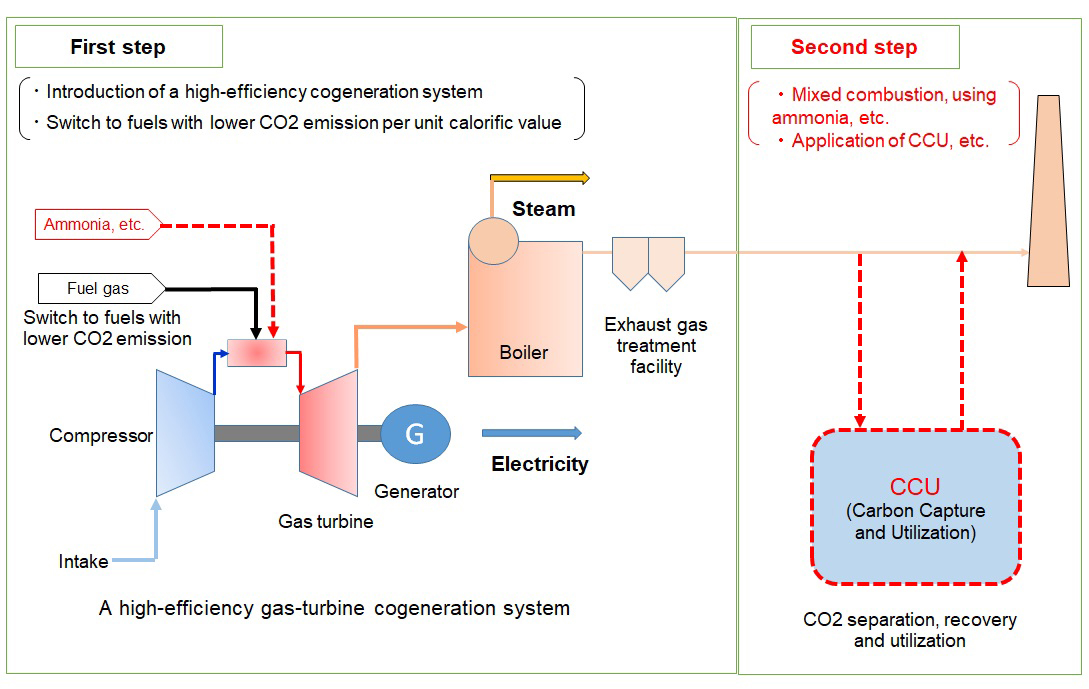

We will introduce a high-efficiency gas engine co-generation system (22,500 kW in total) with a power generation efficiency of 49.5% in our plant in the Ogaki District in Gifu Prefecture. Furthermore, we will establish a system for perfect power supply according to the demand among our plants by being equipped with an in-house electricity supply network connecting each plant and by constructing a smart grid in the same district. In the future, we will put our focus on the utilization of carbon-neutral methane gas, aiming for the following target achievements:

① Reduction in CO2 emissions of approximately 38%

② A system with which approximately 83% of power demand can be supplied from low-carbon on-site power generation.

Description

We have expanded from our original business of hydroelectric power generation in 1912 to our current business of ceramic and electronic products by changing our technologies that we have accumulated since our company’s founding. And now, we plan to take up the challenge of improving the electric power infrastructure toward the realization of a low carbon society while promoting a production increase of our next-generation IC package substrate for the development of an information society.

Utilization of power generation by renewable energy and high-efficiency power

Our company owns a hydroelectric power generation facility (a total of 27,900 kW, renewal of power generating capacity completed by 2015), which has continued its operation since our company’s founding, and generates power with renewable energy. And we have introduced photovoltaic power generation equipment in each plant for generating renewable energy. Moreover, we utilize gas turbine co-generation with a high overall efficiency (four units, at a total of 21,900 kW (already introduced)) at plants with a high steam demand.

① Reinforcement of our low-carbon on-site power generation.

Moreover, we will introduce a total of three high-efficiency gas engine co-generation systems, each with a power generation efficiency of 49.5% (7,500 kW × 3 units, a total of 22,500 kW per two plants), including one unit that was already introduced, sequentially to our plant in the Ogaki District in Gifu Prefecture. As gas engine power generation uses city gas as its fuel, we will promote the utilization of lower-carbon electricity in terms of CO2 emission factors compared with the total factor of a power company. In the future, we will put our focus on the utilization of carbon-neutral methane gas.

[Target achievements] Reduction in CO2 emissions of approximately 38%*

(* Compare a power company’s total factor of 0.484 kg CO2/kWh with CO2 emission factors of 0.3 kg CO2/kWh in the case of gas engine power generation.)

② Establishment of our in-house electricity supply network

We will also establish a smart grid within the same district by building an in-house electricity supply network that connects each plant’s non-utility generator, without just being satisfied with an increase in our power generation capacity through on-site power generation. With this, we aim to establish a system for optimum power supply generated through our on-site power generation equipment according to power demand situation among plants.

[Target achievements] Realization of a power supply from low-carbon on-site generation* to meet an approximately 83% power demand

(* Total of hydroelectric power generation, photovoltaic power generation, and gas engine and gas turbine power generation)

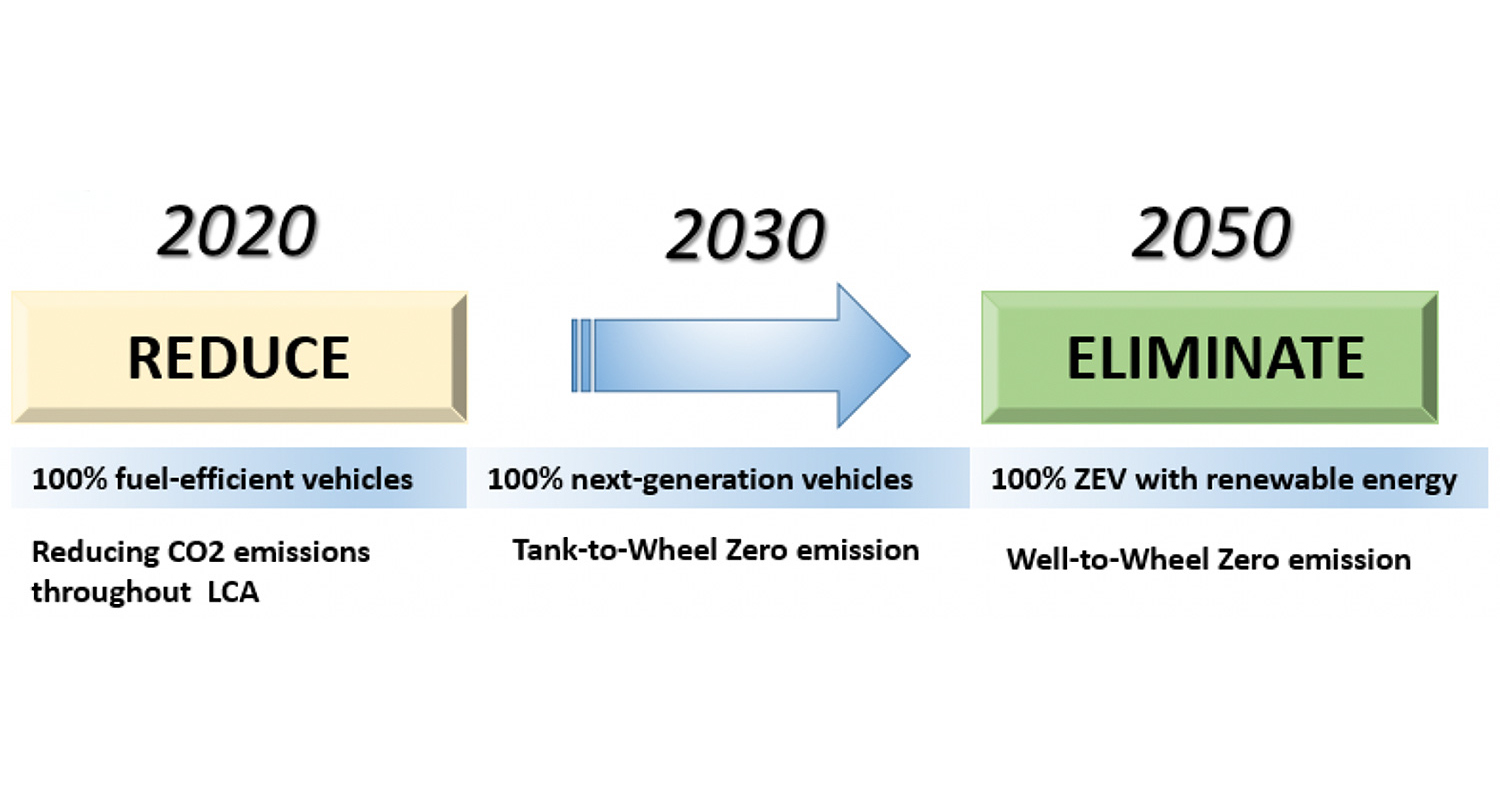

Similar Innovation Challenges

Achieve 2050 decarbonization target with Net Zero Energy House!

Sekisui House, Ltd.

Achieving net-zero emissions by promoting renewable energy use through both our monozukuri and products.

DAIWA HOUSE INDUSTRY CO., LTD.